Sludge brick heavy metal curing agent, sludge brick and preparation method of sludge brick

A curing agent and heavy metal technology, which is applied in the production of clay products, other household utensils, ceramic materials, etc., can solve the problems of complex composition of heavy metal elements, unreasonable control of sintering temperature, long processing cycle, etc., and achieve stable curing effect and high curing effect Visible, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Based on the same inventive concept, the present invention also provides a method for preparing sludge bricks, comprising the following steps:

[0050] (1) Prepare the following raw materials according to the parts by mass:

[0051] Base material: 100 parts;

[0052] Water: 17-22 parts;

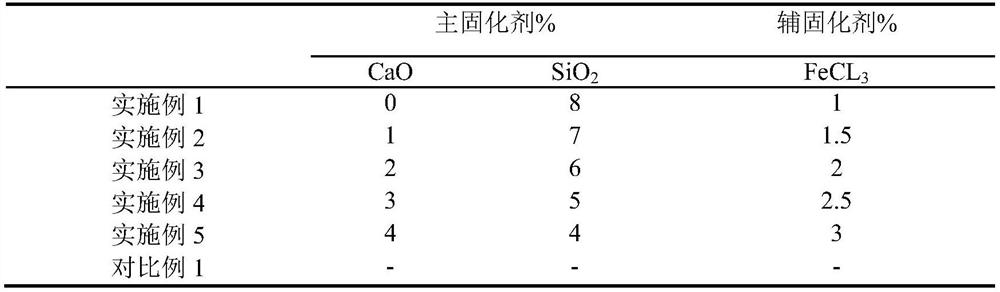

[0053] Main curing agent as mentioned above: 8 parts;

[0054] Auxiliary curing agent as mentioned above: 1 to 3 parts;

[0055] Wherein, the base material includes sludge, clay and fly ash, and the mass-number ratio of the sludge, clay and fly ash is 1:0.5-8.5:0.1-2.5.

[0056] (2) Pour sludge, clay, and fly ash into the container and stir evenly to form a base material mixture;

[0057] (3) Add the main curing agent and the auxiliary curing agent in the container, add water and stir evenly and place it to form the required mixed mud for preparing sludge bricks;

[0058] (4) aging the mixed mud in a sealed bag;

[0059] (5) The aged mixed mud material is packed into a mold and pre...

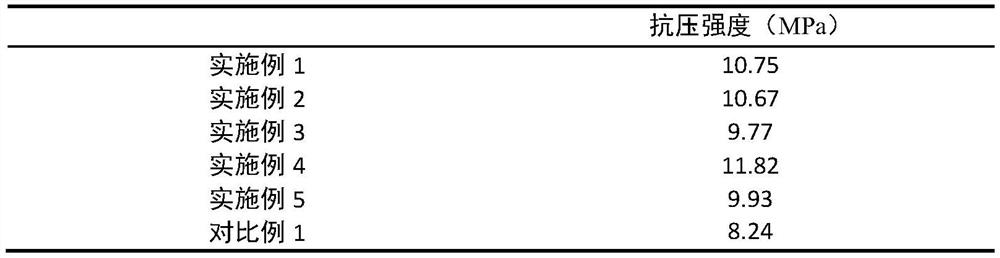

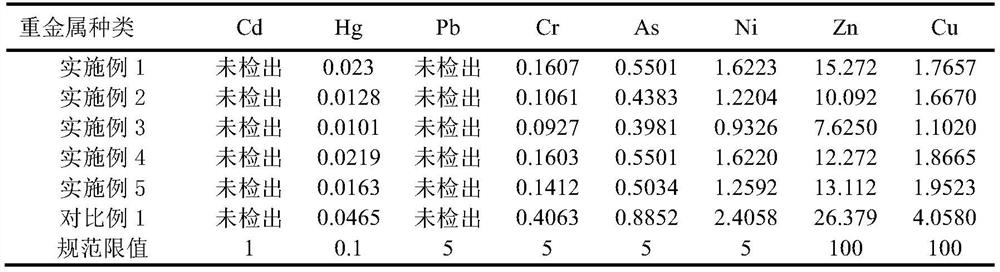

Embodiment 1

[0075] Weigh the dry pulverized sludge, clay and fly ash as the base material, wherein the mass ratio of sludge, clay and fly ash is 1:1.33:0.67, based on the dry basis weight of the base material, weigh The tap water of amount 17~22% by weight.

[0076] Taking the dry basis weight of the base material as a basis, take by weighing 8% of the main curing agent by weight, and take by weighing 1% of the auxiliary curing agent by weight; wherein in the main curing agent, CaO and SiO 2 The mass-to-number ratio is 0:8.

[0077] Pour the weighed sludge, clay, and fly ash into a container and stir evenly to form a base material mixture.

[0078] Add the main curing agent and auxiliary curing agent into the container, stir again, add water, stir evenly and place it to form the mixed mud required for preparing sludge bricks.

[0079] Put the mixed sludge into a sealed bag for aging.

[0080] Put the aged mud into the mold, press it under the press, and disassemble the mold.

[0081] ...

Embodiment 2

[0084] Same as Example 1, the difference is only in the content of heavy metal curing agent for sludge bricks. In this embodiment, take the dry basis weight of the base material as a benchmark, weigh 8% by weight of the main curing agent, and take by weighing 1.5% by weight of the auxiliary curing agent , where CaO and SiO in the curing agent 2 The mass-to-number ratio is 1:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com