Chromatographic filler, and preparation method and application thereof

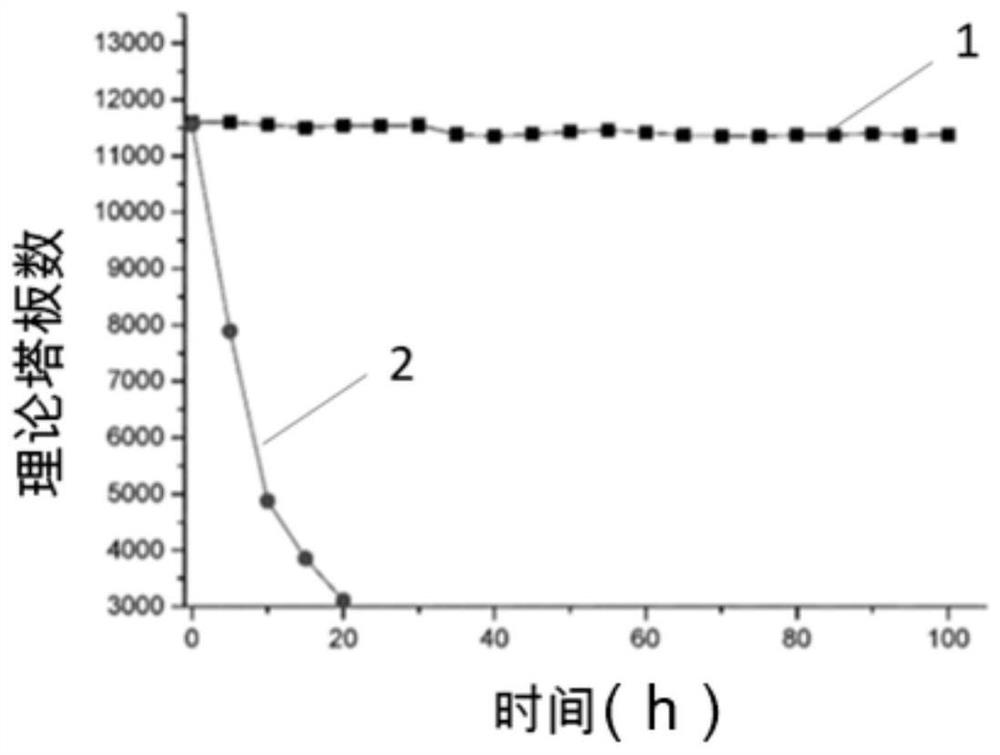

A chromatographic packing and raw material technology, applied in the field of analytical chemistry, can solve the problems of alkali resistance defects and slow mass transfer, and achieve the effects of uniform and controllable pore size, improved alkali resistance, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A chromatographic filler, the preparation method thereof includes the following steps:

[0060] (1) 1 g F127 polyether template agent, 0.16 g of a hexadalkyltrimethylammonium ammonium ammonium dielectric (CTAb template), 30 ml deionized water and 6 ml ethanol were mixed under stirring conditions of 500 rpm, Get clarified solution;

[0061] (2) 1.76 g of orthosilicate (TEOS), 0.85 g 1, 4-di (triethoxyla) benzene (BTEB) and step (1) were subjected to a stirring condition of 500 rpm under a rotational speed. The reaction was mixed for 1 h, at 80 ° C for 5 h, and the reaction was reacted at 130 ° C for 12 h, resulting in an intermediate product;

[0062] (3) The intermediate product obtained by flushing step (2) was dried at 50 ° C for 12 h, and the intermediate product was stirred in anhydrous ethanol at 50 ° C for 24 h, and the chromatogram filled.

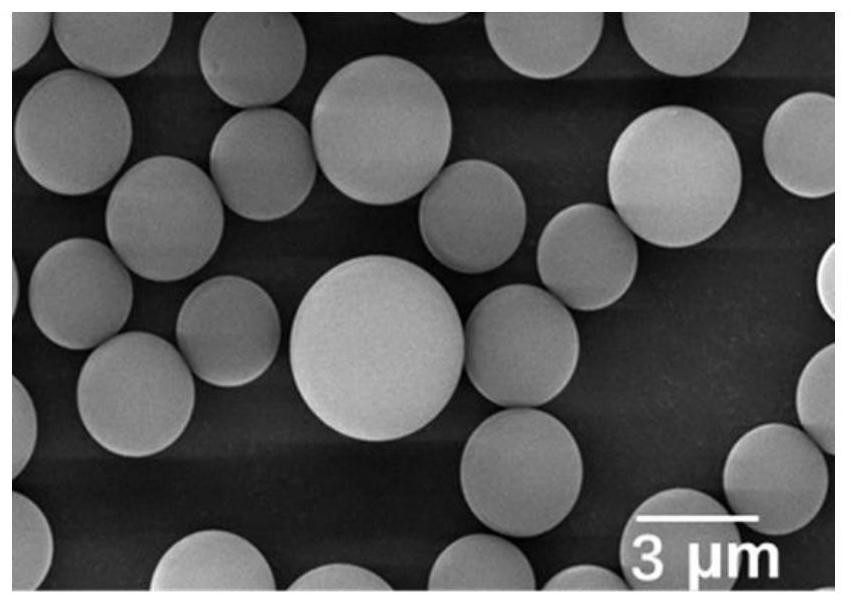

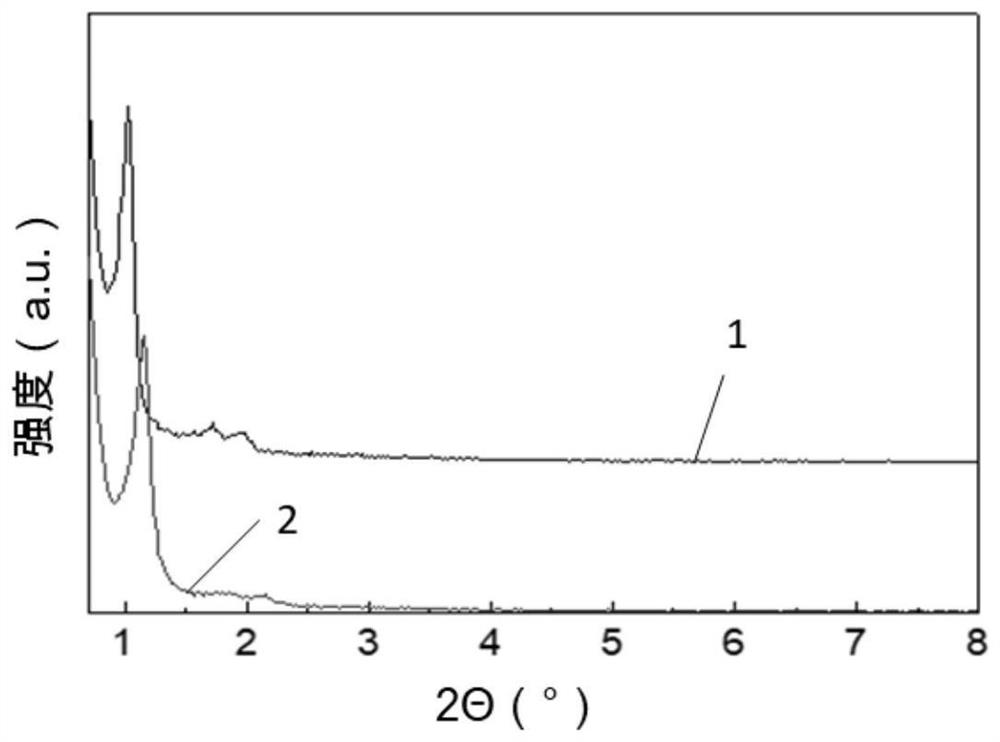

[0063] The chromatographic filler obtained by the present embodiment is 3.5 μm, a pore size of 8.9 nm, a specific surface area ...

Embodiment 2

[0065] A chromatographic filler, the preparation method thereof includes the following steps:

[0066] (1) 2G F127 polyether template agent, 0.32 g of CTAb template, 50 ml deionized water and 13 ml of ethanol were mixed under stirring of 600 rpm under stirring conditions of 600 rpm to obtain a clear solution.

[0067] (2) The clarified solution obtained by 3.52 g of TEOS, 1.7G BTEB and step (1) was mixed under stirring conditions of 600 rpm, and at 70 ° C at 70 ° C for 6 h, and at 120 ° C for 14 h, the intermediate product was obtained;

[0068] (3) The intermediate product obtained by flushing step (2) was carried out at 70 ° C for 12 h, and the intermediate product was stirred in anhydrous ethanol at anhydrous ethanol at 60 ° C for 24 h, and the chromatographic filler was obtained.

[0069] The chromatographic filler obtained by this embodiment is 2.8 μm, a pore size of 7.1 nm, a specific surface area of 472m. 2 / g, the variation coefficient is 12.5%.

Embodiment 3

[0071] A chromatographic filler, the preparation method thereof includes the following steps:

[0072] (1) 0.5 g of F127 polyether template, 0.08 g of CTAb template, 15 ml deionized water and 2.5 ml of ethanol were mixed under stirring conditions of 400 rpm under a stirring conditions of 400 rpm, resulting in a clear solution;

[0073] (2) The clear solution obtained by 0.88 g of TEOS, 0.42 g of BTEB and step (1) was mixed with 0.5 h, and at 85 ° C for 4 h, at 140 ° C for 10 h, to obtain an intermediate product under stirring conditions of 400 rpm.

[0074](3) The intermediate product obtained by flushing step (2) was carried out at 60 ° C for 12 h, and the intermediate product was stirred in anhydrous ethanol at 60 ° C for 24 h, and the chromatographic filler was dried.

[0075] The chromatographic filler obtained by this embodiment is 3.1 μm, a pore size of 9.6 nm, a specific surface area of 450m. 2 / g, the variation coefficient is 10.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com