A kind of preparation method of nano mesoporous material

A nano-mesoporous material and nano-mesoporous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex processing, expensive templating agent, poor continuity of mesoporous materials, etc. , achieving great application prospects, avoiding synthesis difficulties, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0031] Experimental Example 1: Nano Mesoporous Oxide NiO

[0032] Synthetic raw materials: sucrose, urea, Ni(NO 3 ) 2· 6H 2 O (nickel nitrate)

[0033] (1) Weigh 100 g sucrose, 1 g urea and 1 g Ni(NO 3 ) 2· 6H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 100°C, and the stirring was continued for 60 minutes until the drug in the beaker formed a uniform molten liquid.

[0034] (2) Put the beaker containing the molten liquid sample in (1) into an oven at 120°C, and react for 48 hours to obtain a dark brown puffy solid.

[0035] (3) Grind the product obtained in (2) with a mortar and put it in a crucible. The product obtained by the reaction is in N 2 Heat treatment at 1100°C for 2 hours under protection.

[0036] (4) Calcining the black solid described in (3) at 450°C in air for 24 hours to obtain nanometer mesoporous metal oxide NiO. The XRD test shows that the particle size of nano...

experiment example 2

[0037] Experimental Example 2: Nano Mesoporous MgO-Al 2 o 3

[0038] Synthetic raw materials: glucose, urea, Mg(NO 3 ) 2· 6H 2 O (magnesium nitrate), Al(NO 3 ) 3· 9H 2 O (aluminum nitrate)

[0039] (1) Weigh 1 g glucose, 10 g urea, 0.1 g Mg(NO 3 ) 2· 6H 2 O and 0.1 g Al(NO 3 ) 3· 9H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 220°C, and the stirring was continued for 10 min until the medicine in the beaker formed a molten liquid.

[0040] (2) Put the beaker containing the molten liquid in (1) into an oven at 250°C and react for 1 hour to obtain a dark brown puffy solid.

[0041] (3) Grind the product obtained in (2) with a mortar and put it in a crucible. The product obtained by the reaction is in N 2 Heat treatment at 250°C for 40 hours under protection,

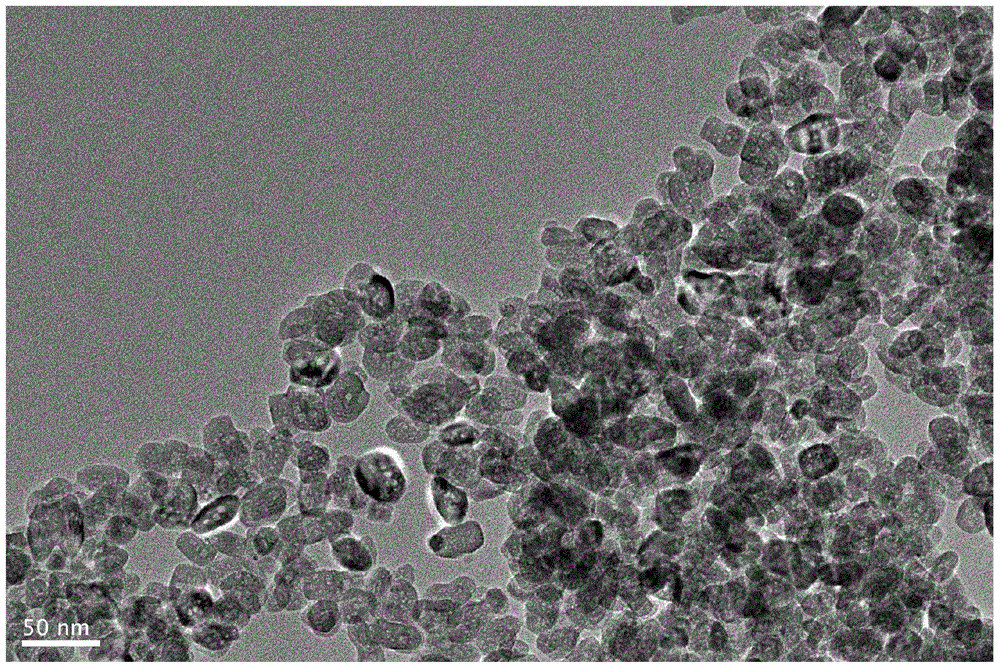

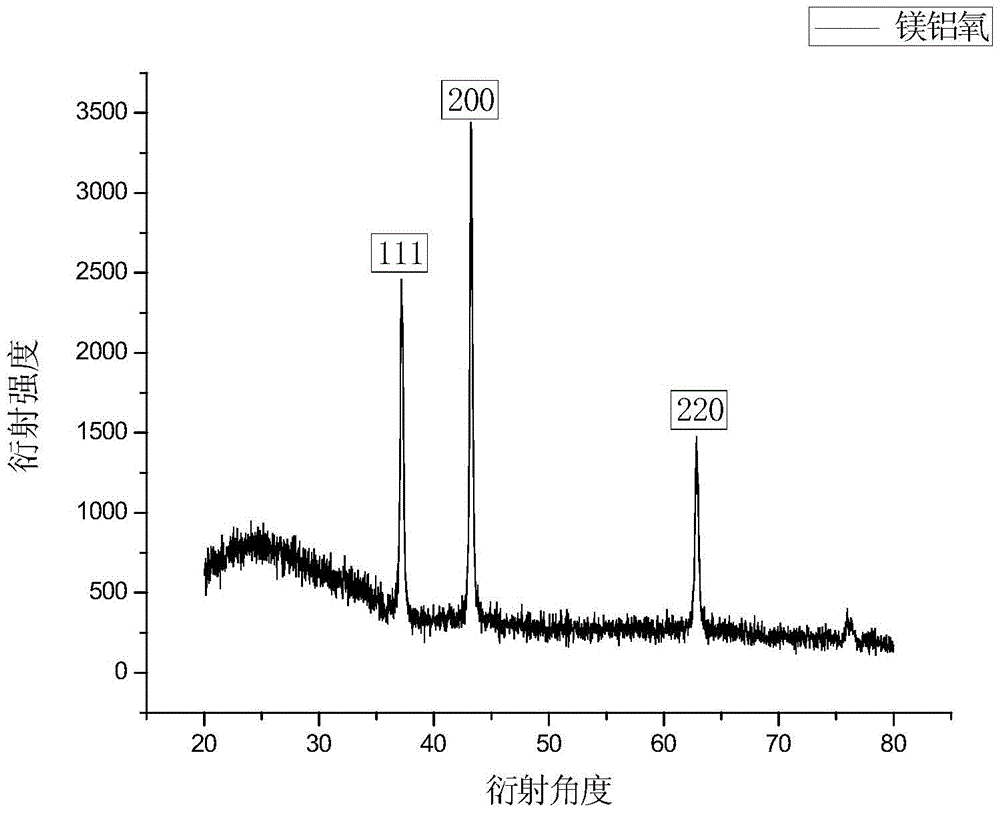

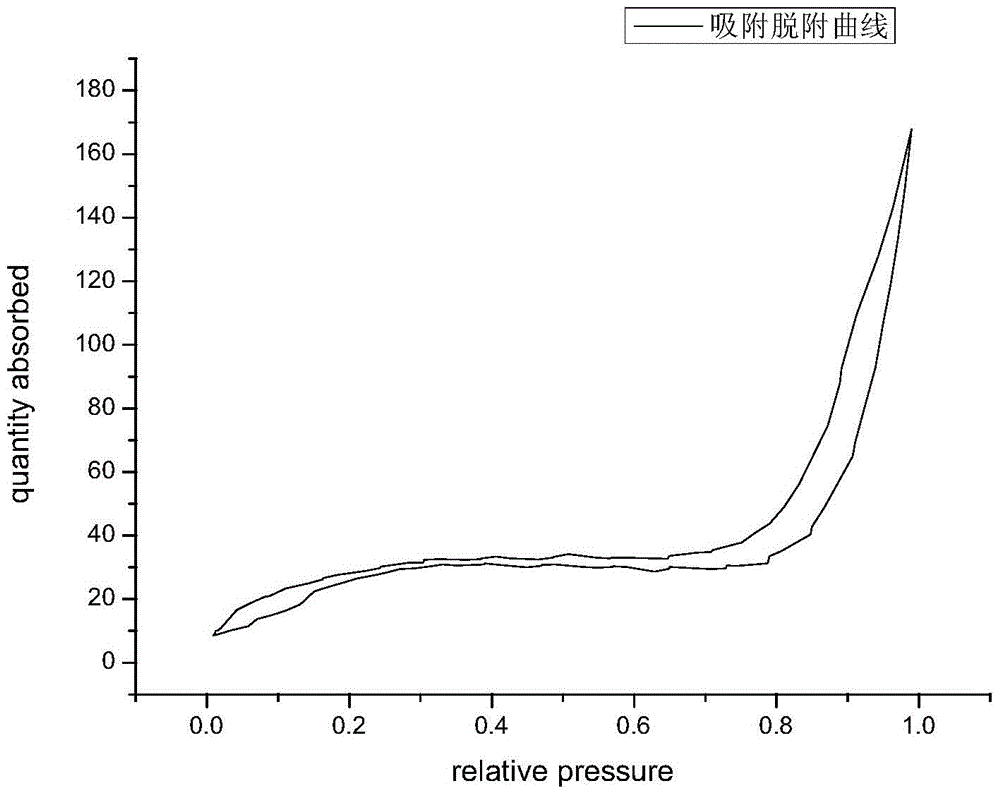

[0042] (4) Calcining the black solid described in (3) at 900°C in air for 7 hours to obtain nano-mesoporous MgO-Al 2...

experiment example 3

[0044] Experimental Example 3: Nano Mesoporous TiO 2

[0045] Synthetic raw materials: glucose, urea, TiOSO 4 (titanyl sulfate)

[0046] (1) Weigh 5 g of glucose and 1 g of urea into a 100 mL beaker, and then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 200°C, and the stirring was continued for 10 min until the drug in the beaker was in a molten state.

[0047] (2) Weigh 0.2 g TiOSO 4 And add it to the molten liquid mentioned in (1), and keep stirring for 10 minutes until the solution is clear. Then put the beaker into an oven at 200°C and react for 8 hours to obtain a dark brown puffy solid.

[0048] (3) Grind the product obtained in (2) with a mortar and put it in a crucible. The product obtained by the reaction was calcined at 700°C in the air for 7 hours to obtain nano-mesoporous TiO 2 . Figure 4 nanometer mesoporous TiO 2 The TEM picture, the nano-mesoporous TiO can be seen in the figure 2 It is rod-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com