Pneumatic control device for buried pipe in goaf and using method

A goaf and pneumatic technology, applied in the direction of mining equipment, valve equipment, safety equipment, etc., can solve the problems of potential safety hazards, and achieve the effect of saving the process of cutting buried pipes, low cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

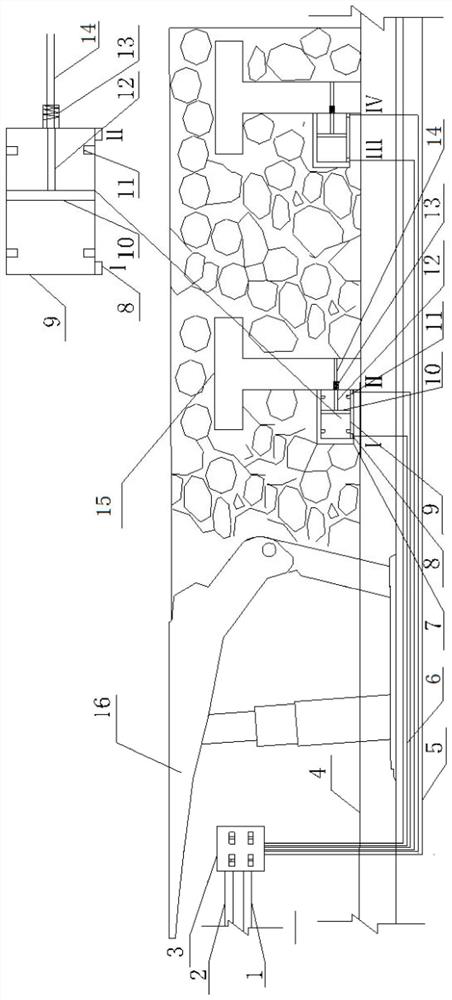

[0024] Such as figure 1 As shown, this embodiment proposes a goaf buried pipe pneumatic control device, including a pneumatic pressure control device, a pneumatic switching device, a T-shaped buried pipe 15 and a low negative pressure gas drainage pipeline 4, wherein the T-shaped buried pipe The output port of 15 is connected with the low negative pressure gas drainage pipeline 4. The pneumatic switching device includes a pneumatic valve 9, a pneumatic sliding plate 10, a baffle plate 14 and a linkage mechanism. The pneumatic valve 9 has a cavity inside, and the pneumatic sliding plate 10 can be slidably installed Inside the pneumatic valve 9, the pneumatic slide plate 10 divides the interior of the pneumatic valve 9 into a first pneumatic chamber and a second pneumatic chamber. The device can drive the pneumatic sliding plate 10 to slide in the pneumatic valve 9 by adjusting the air pressure in the first pneumatic chamber and the second pneumatic chamber, and the baffle 14 is...

Embodiment 2

[0032] This embodiment proposes a method for using the goaf buried pipe pneumatic control device, using the goaf buried pipe pneumatic control device in Embodiment 1, including the following steps,

[0033] Step 1. Connect the pneumatic valve 9 control switch 3 in the pneumatic pressure control device to the first pneumatic chamber and the second pneumatic chamber of the pneumatic switching device through the air guide tube 6, and place the baffle plate 14 in the low negative pressure gas drainage pipeline 4 and the junction of the T-shaped buried pipe 15;

[0034] Step 2. When installing and connecting the T-shaped buried pipe 15, install the baffle plate 14 inside it, install the pneumatic valve 9 on the side wall of the T-shaped buried pipe 15, and connect the air guide pipe 6 with the outlet and the air guide port 8;

[0035] Step 3. Control the switch 3 to switch the pressure difference between the first pneumatic chamber and the second pneumatic chamber by switching the ...

Embodiment 3

[0037] In combination with Embodiment 1 and Embodiment 2, this embodiment describes in detail the specific structure and usage method of the goaf buried pipe pneumatic control device.

[0038] First, when installing and connecting the T-shaped buried pipe 15, a baffle plate 14 is installed inside it, and the downhole pressure inlet air pipe 1 and the downhole pressure return air pipe 2 are connected with the pneumatic valve 9 control switch 3; the pneumatic valve 9 control switch 3 and The air guide tube 6 is connected, the air guide tube 6 is placed in the protective tube 5, the protective tube 5 is placed under the low negative pressure gas extraction pipe, the T-shaped buried pipe 15 is connected with the low negative pressure gas extraction tube, and the The air guide tube 6 is led out from the protective tube 5 and connected with the air guide port 8 of the pneumatic valve 9, the pneumatic valve 9 is connected with the baffle plate 14, and the protective shell 7 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com