Fire resistance performance test and detection protection device for visual hydrogen explosion corrugated flame arrester

A technology of protective device and flame arrester, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of misjudgment response, lack of systematic analysis and evaluation of fire resistance characteristics, and failure to effectively measure the fire resistance temperature change characteristics of fire resistance core, etc., to achieve Prevent misjudgment and untimely response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

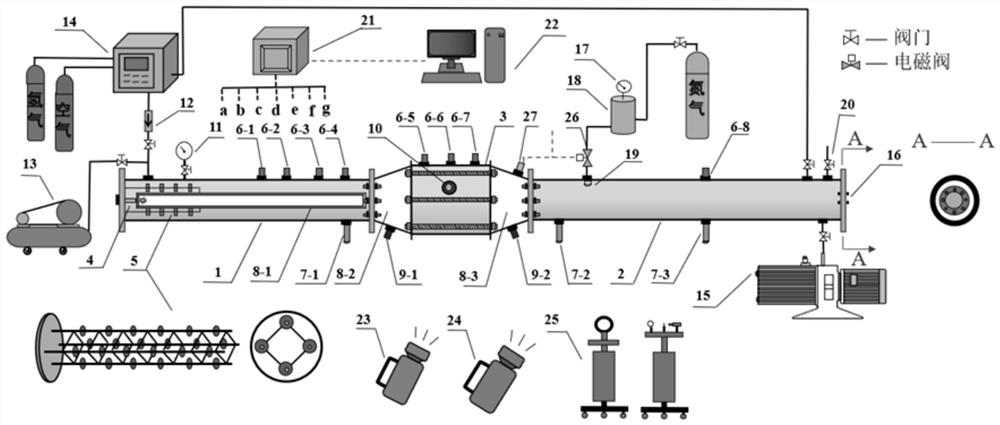

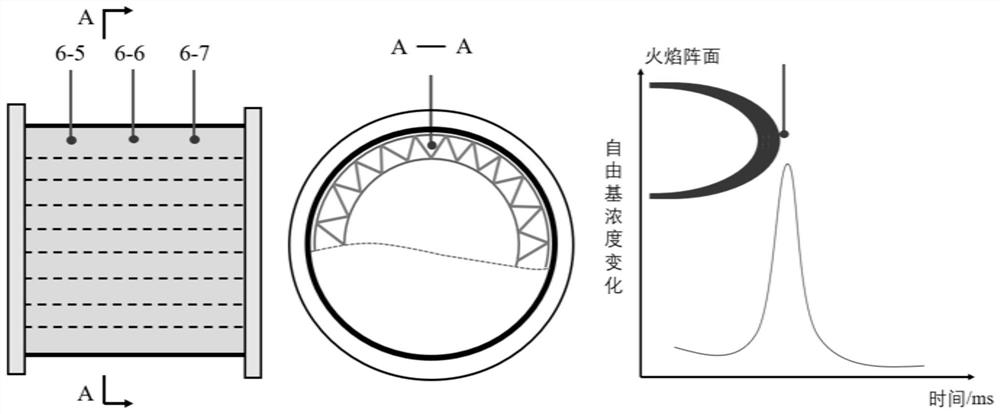

[0018] This implementation is suitable for the fire arresting performance test and detection protection of the hydrogen explosion corrugated flame arrester. Its structure is shown in the figure, including: detonation section pipeline 1; protection section pipeline 2; corrugated flame arrester 3; adjustable high-voltage igniter 4; flame acceleration Device 5; flame ion probes 6-1, 6-2, 6-3, 6-4, 6-5, 6-6, 6-7 and 6-8; high frequency pressure sensors 7-1, 7-2 and 7-3; visual tempered glass windows 8-1, 8-2 and 8-3; high-frequency B-type thermocouples 9-1 and 9-2; metal surface temperature sensor 10; high-precision vacuum pressure gauge 11; one-way Valve 12; air compressor 13; circulating gas distribution instrument 14; vacuum pump 15; explosion relief device 16; high-precision pressure gauge 17; high-pressure inhibitor storage tank 18; high-pressure fine nozzle 19; exhaust valve 20; Program control and data acquisition system 22; high-speed camera system 23; high-speed infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com