Industrial waste gas emission quality remote real-time monitoring system

An industrial waste gas and real-time monitoring technology, which is applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problems of inconvenience, single type of detection, and inability to detect waste gas, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

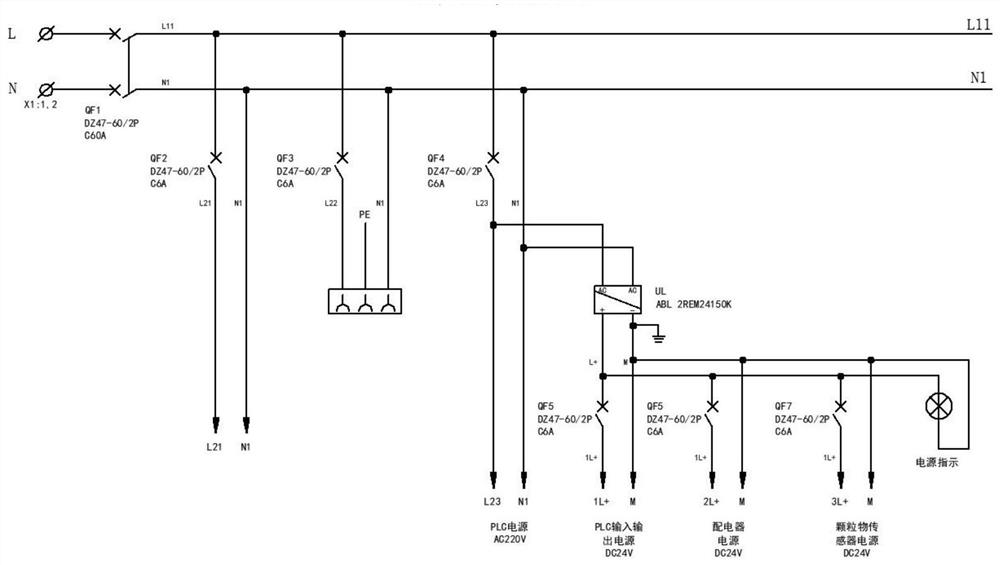

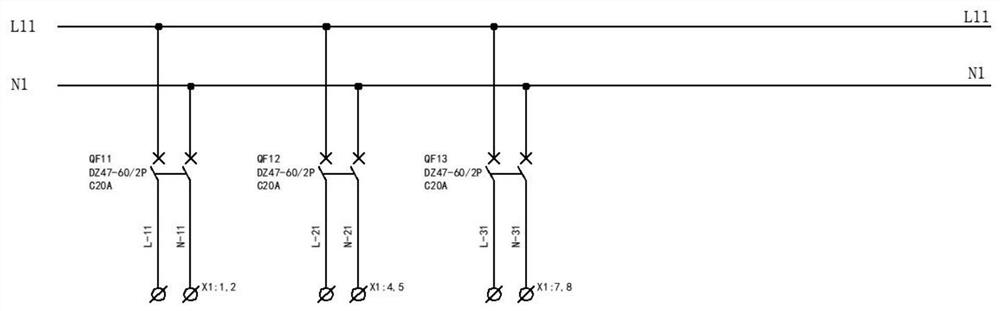

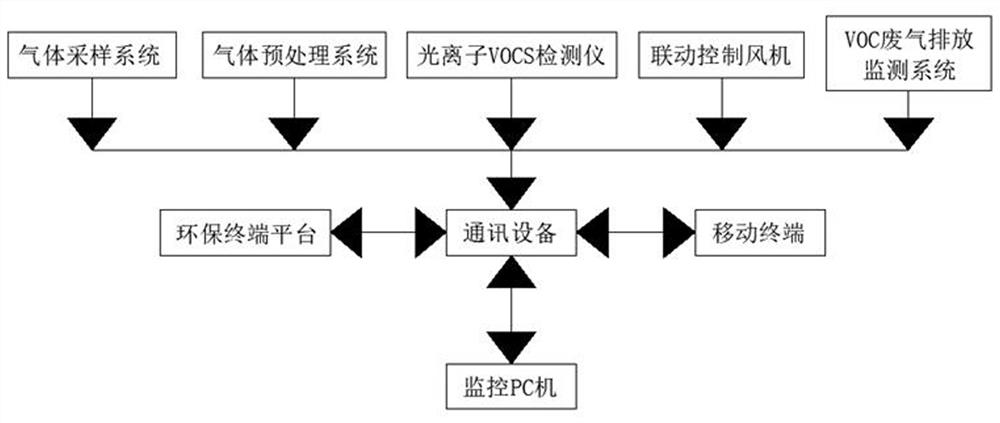

[0050] refer to Figure 1-14 , a remote real-time monitoring system for industrial waste gas emission quality, comprising a monitoring PC, the monitoring PC is connected to a communication device, the communication device is connected to a mobile terminal and an environmental protection terminal platform, and the communication device is connected to a gas sampling system, a gas pre- Treatment system, photoion VOCS detector, linkage control fan and VOC exhaust emission monitoring system;

[0051] The gas sampling system includes a gas analyzer, a gas sampling control board and a micro air pump;

[0052] The gas pretreatment system includes drying equipment, pressure regulating equipment, micro air pump and gas pretreatment control board;

[0053] The photoion VOCS detector includes PID photoion generator, steam trap, dehumidifier, flow meter, micro air pump and photoion VOCS detection control board;

[0054] The linkage control fan includes the driver, several groups of fans ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com