Hydrogen storage material, negative electrode and nickel hydrogen secondary battery

A hydrogen storage material and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as insufficient discharge characteristics, and achieve the effect of excellent low-temperature discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] In order to prepare hydrogen storage alloy particles having the composition shown in Table 1, first, raw materials other than Mg were weighed and melted in an argon atmosphere in a high-frequency furnace to form an alloy melt. Next, the pouring temperature of this alloy melt was set at 1400° C., and it was rapidly cooled and solidified by a strip casting method using a single-roll casting device using a copper water-cooled roll to obtain an alloy slab with an average thickness of 0.35 mm. The obtained alloy cast flakes were pulverized using a ball mill to obtain alloy powder having an average particle diameter (D50) of 75 μm. The composition of the obtained alloy powder was analyzed by ICP, and the result was La 0.14 SM 0.80 Zr 0.02 Ni 3.26 al 0.24 .

[0093] The above-mentioned alloy powder and metal Mg powder with an average particle diameter (D50) of 110 μm were thoroughly mixed with a mortar, kept at 700° C. for 30 minutes in an argon atmosphere, and then raise...

Embodiment 2~28、 comparative example 3~5 and 7~9

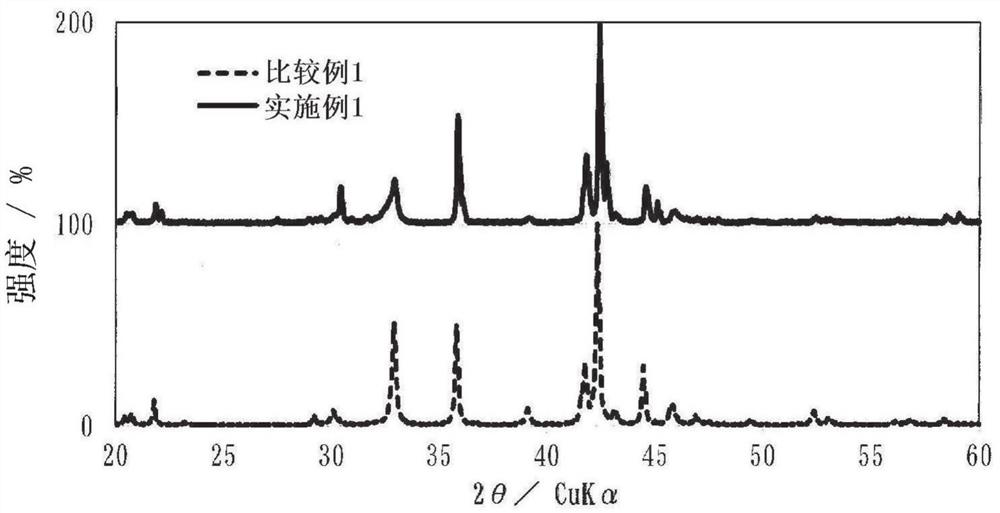

[0110] Except for changing the composition of the hydrogen storage material, the composition of the hydrogen storage alloy particles, the amount of Ni powder, and the heat treatment conditions as shown in Tables 1 and 2, Examples 2 to 28 were prepared in the same manner as in Example 1, and comparative Examples 3-5 and 7-9 hydrogen storage materials. However, instead of the above-mentioned Ni powder with an average particle diameter (D50) of 0.6 μm, Ni powder with D50 of 2.4 μm was used in Example 19, Ni powder with D50 of 2.0 μm was used in Example 20, and Ni powder with D50 of 2.0 μm was used in Example 21. D50 is Ni powder of 3.5 μm. Table 3 shows the results of X-ray diffraction measurement and battery characteristic evaluation test performed in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com