Stator adhesive laminated core and rotating electric machine

A technology for stators and bonding parts, applied in the manufacture of stator/rotor bodies, motors, adhesive types, etc., can solve the problem of insufficient bonding ability, insufficient insulation ability of insulating coating, poor excitation efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

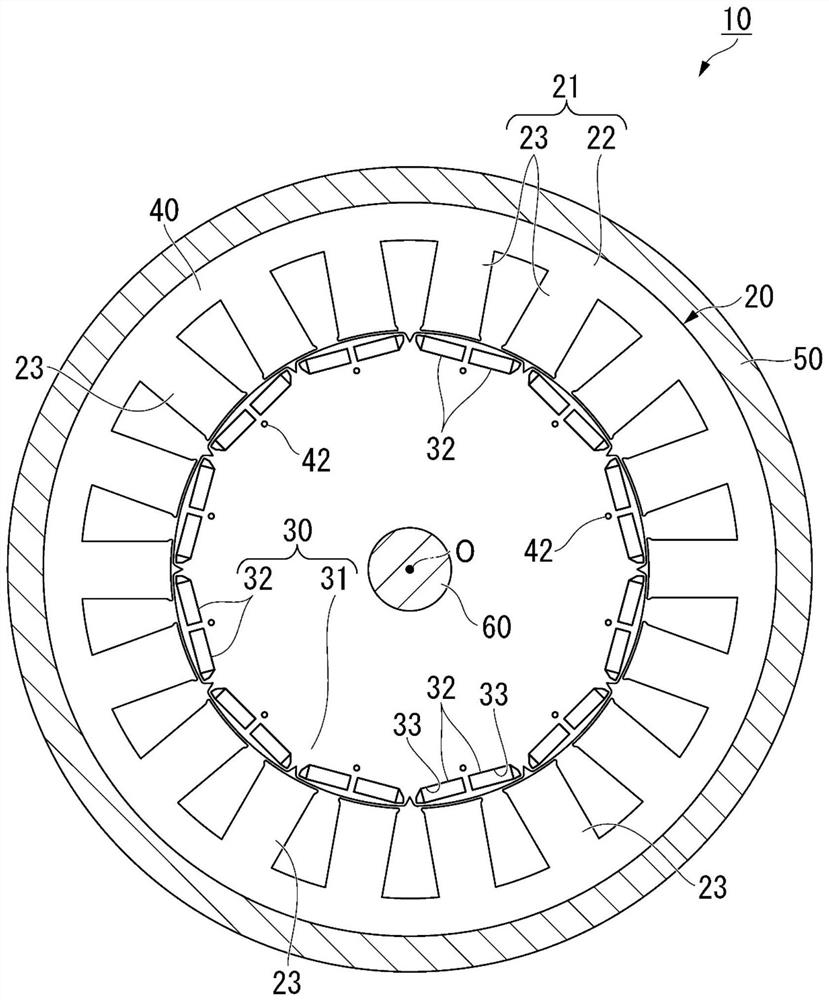

[0080] use Figure 4 The manufacturing apparatus 100 shown manufactures the above-mentioned stator core 21 while changing various manufacturing conditions.

[0081] First, the manufacturing apparatus 100 will be described. In this manufacturing apparatus 100 , the electrical steel sheet P is fed out from a coil C (strip) in the direction of arrow F, and punched multiple times by dies arranged on each stage to gradually form the shape of the electrical steel sheet 40 . Then, an adhesive is applied to the lower surface of the electrical steel sheet 40, and the punched electrical steel sheets 40 are stacked, and pressure is applied while raising the temperature. As a result, the adhesive is cured to form the bonding portion 41, and bonding is completed.

[0082] Such as Figure 4 As shown, the manufacturing apparatus 100 includes: a first-stage punching station 110 at a position closest to the steel coil C; The punching station 120 of the second stage; and the adhesive coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com