Pollutant collection and treatment equipment for oncology department nursing

A technology for processing equipment and pollutants, which is applied in the field of pollutant collection and treatment equipment for oncology nursing, which can solve the problems of personal safety, small size of metal needles, and unrealistic problems, so as to achieve safe working process, avoid sticking phenomenon, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

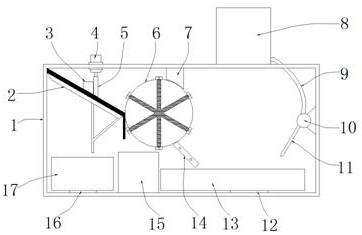

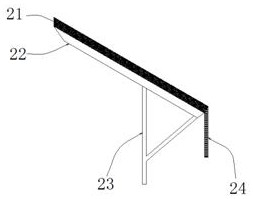

[0034] refer to Figure 1-2 with Figure 9 , a pollutant collection and treatment device for oncology care, including a treatment shell 1, an opening (not shown in the figure) is provided on the top side of the treatment shell 1, and a slope is fixedly installed directly below the opening. The draining device 2 provided, the draining device 2 includes a draining plate 21, the draining plate 21 is evenly provided with draining holes, and the top of the processing shell 1 is vertically provided with a push rod that runs through the top of the processing shell 1 on one side of the opening Motor 4, the output shaft of push rod motor 4 is vertically downward, and its output shaft is fixedly connected with the baffle plate 5 that fits with the top of draining device 2, so that the pollutants produced in the nursing process of the oncology department can be discharged on the draining plate 21. Cooperate with the function of the baffle plate 5 to drain water when standing still, so t...

Embodiment 2

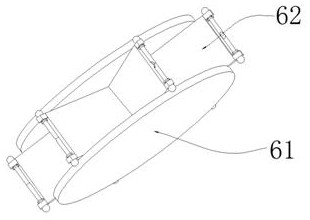

[0038] refer to figure 1 , Figure 3-8, one side of the processing housing 1 is fixedly installed with a servo motor 18 whose output shaft points to the horizontal direction, the first pressure sensor 16 is electrically connected to the servo motor 18, and the output shaft of the servo motor 18 penetrates and extends to the inside of the processing housing 1, And concentrically connected with a screening mechanism 6, the screening mechanism 6 is attached to the bottom of the draining device 2, that is, after the working steps of the first embodiment are completed, the first pressure sensor 16 controls the servo motor 18 to work, thereby driving its electric The connected screening mechanism 6 rotates so that the falling pollutants can be collected. The screening mechanism 6 has two sets of rotating plates 61 arranged in parallel, and several groups of adsorption devices 62 are fixedly installed in an annular array between the rotating plates 61 , the adsorption device 62 incl...

Embodiment 3

[0043] refer to figure 1 , the inside of the processing housing 1 is provided with a needle collection box 13 below the lower end of the power-off part 14, and the top of the processing housing 1 is fixedly installed on the side away from the opening. The storage box 8 is equipped with a Cured resin materials, etc., one side of the lower part of the storage box 8 is connected with a conduit 9 that runs through and extends to the inside of the processing shell 1, and one end of the conduit 9 is connected with a high-viscosity pump 10 that is fixedly connected to the inner wall of the processing shell 1, and the needles are collected. The bottom end of the box 13 is provided with a second pressure sensor 12, and the second pressure sensor 12 is electrically connected with the high viscosity pump 10, and the output end of the high viscosity pump 10 is connected with a nozzle 11 pointing to the inside of the needle collection box 13, when the needle collects When the quality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com