Method and device for preparing friction nanometer generator based on 3D printing

A nanogenerator and 3D printing technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of huge differences in the output performance of non-flexible triboelectric nanogenerators, and achieve high-efficiency electrical performance, good electronegativity, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

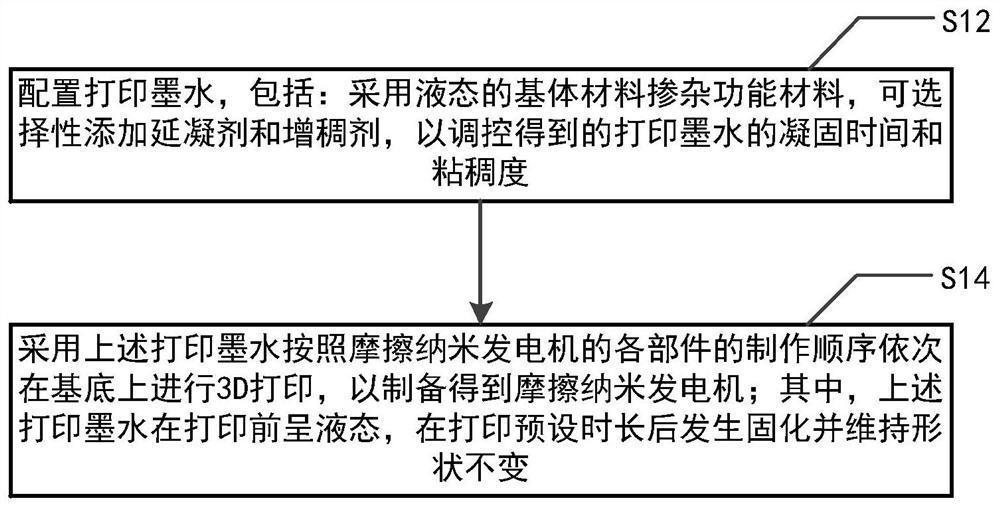

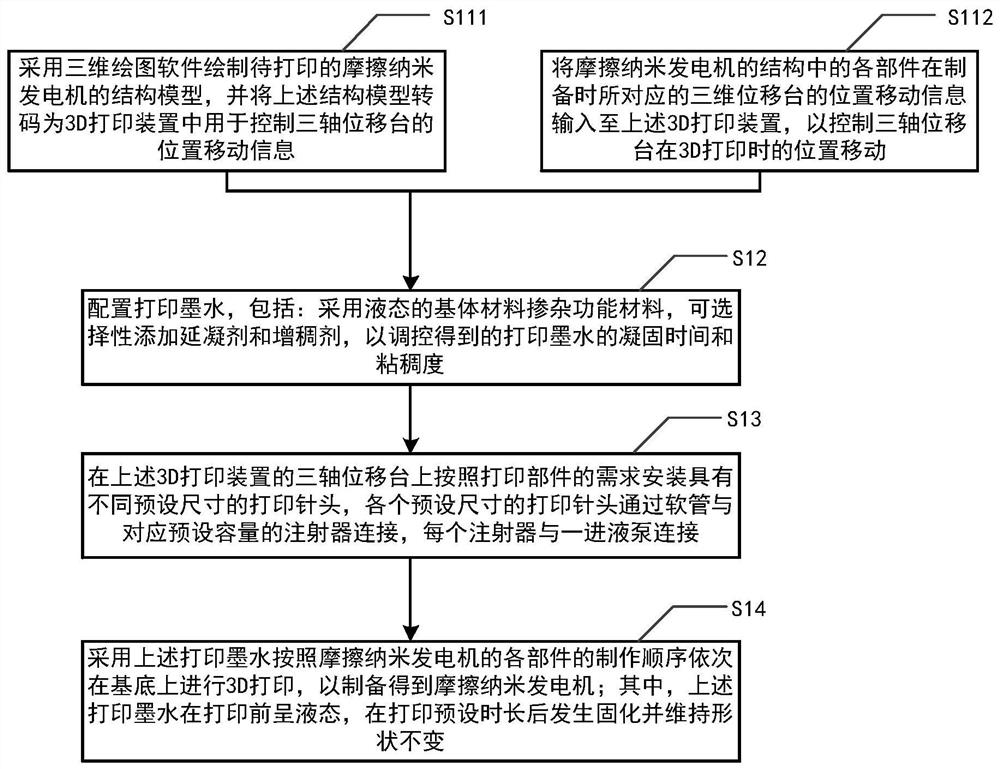

[0051] figure 1 It is a flowchart of a method for preparing a triboelectric nanogenerator according to an embodiment of the present disclosure.

[0052] refer to figure 1 As shown, the method for preparing a triboelectric nanogenerator based on 3D printing provided by the embodiment of the present disclosure includes the following operations: S21 and S22.

[0053] In operation S21, configuring the printing ink includes: doping the functional material with a liquid matrix material, and optionally adding a setting retarder and a thickener to control the setting time and viscosity of the obtained printing ink. The above-mentioned functional materials are functional materials used to prepare various components of the triboelectric nanogenerator.

[0054] In operation S22, the above-mentioned printing ink is used to perform 3D printing on the substrate in sequence according to the production sequence of the components of the triboelectric nanogenerator to prepare a triboelectric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com