Preparation method of automobile paint with high drying speed

A technology of drying speed and car, applied in the field of car paint, can solve the problems of low accuracy, high energy consumption, waste of manpower and material resources, etc., to save time, improve the proportioning speed, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

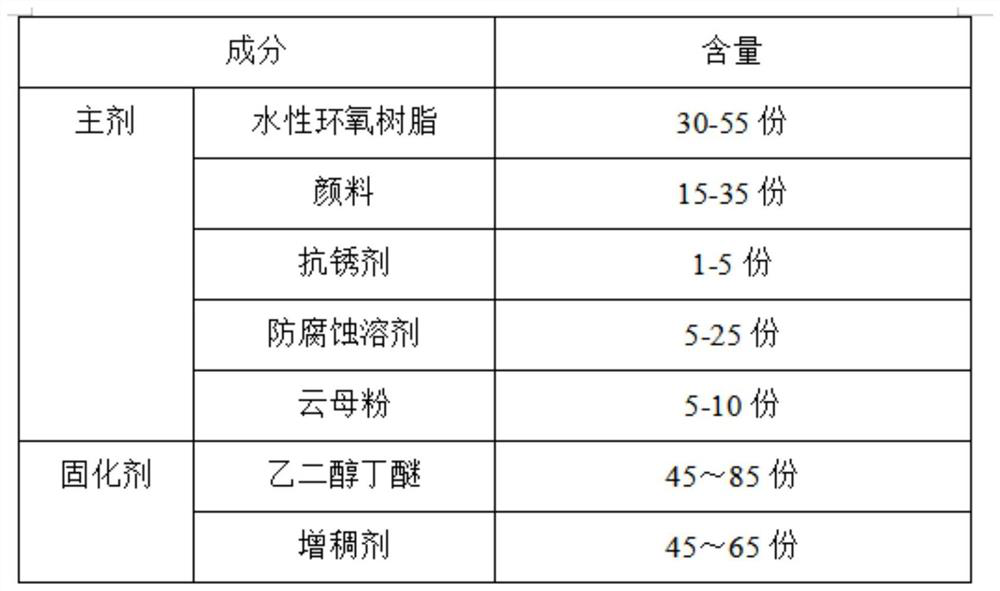

[0028] Such as figure 1 As shown, a car paint with fast drying speed, the car paint includes a main agent and a curing agent, the raw materials of the main agent and the curing agent are respectively according to the volume content: main agent component: water-based epoxy resin 30 -55, pigment 15-35, anti-rust agent 1-5, anti-corrosion solvent 5-25, mica powder 5-10; curing agent components: ethylene glycol butyl ether 45-85, thickener 45-65; The volume ratio of the paint component and the curing agent component is 1-4:2.

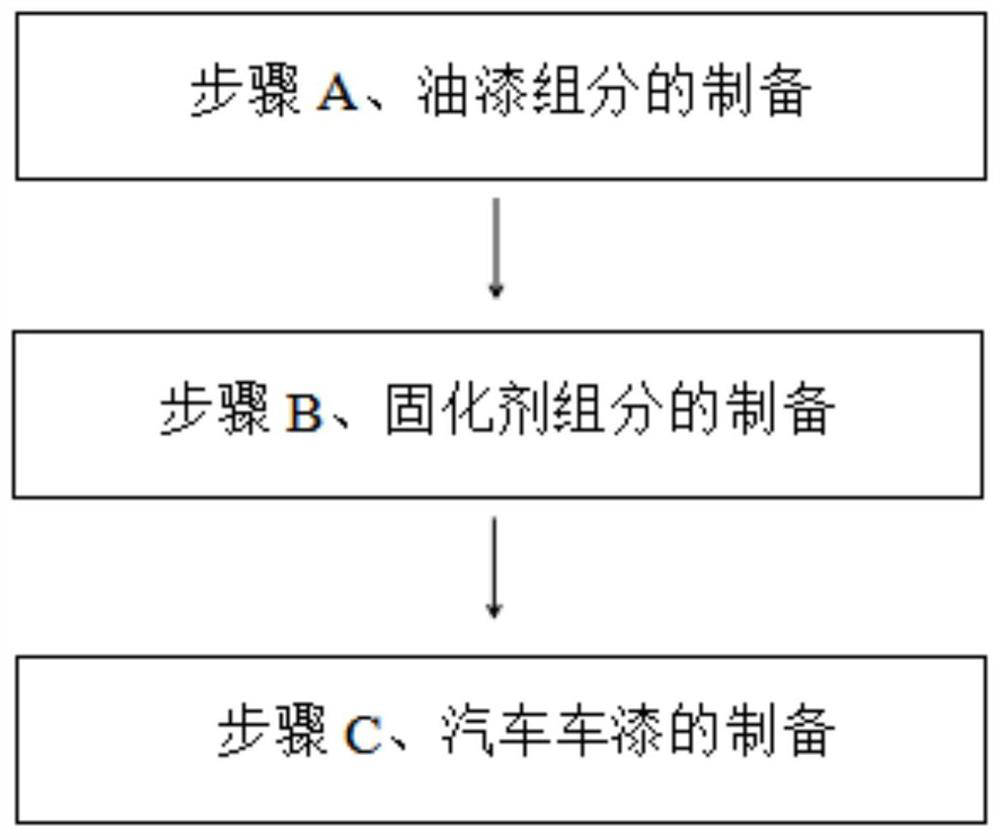

[0029] Such as image 3 Shown, the invention discloses a kind of preparation method of automobile paint, and this method comprises the following steps:

[0030] A: Preparation of paint components:

[0031] (1) Transport 10-25 parts of water-based epoxy resin, 1-5 parts of anti-rust agent, 5-25 parts of anti-corrosion solvent, and 5-10 parts of mica powder into the mixing tank according to volume parts through a single delivery pump, and stir evenly .

...

Embodiment 2

[0043] A kind of preparation method of the car paint that drying speed is fast among the present invention comprises the following steps:

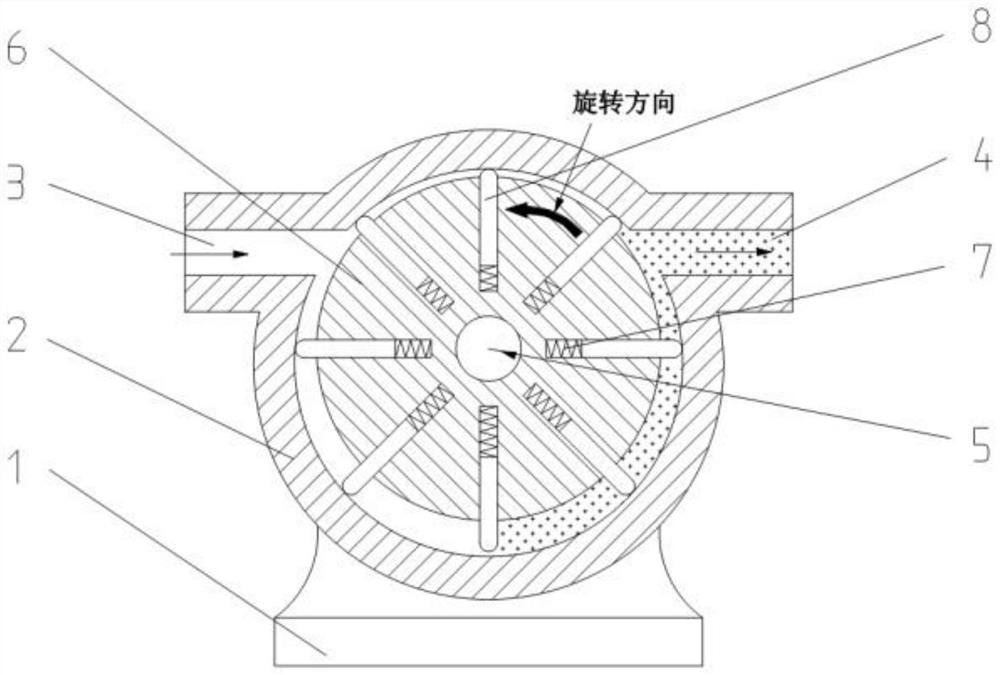

[0044] Start the controller, and set the number of parts of each component of the paint to be delivered through the controller. Each component of the paint is delivered independently through different single-part delivery pumps. The controller controls the stepping motor to start, and the stepping motor drives the drive shaft. 5 rotates, the drive shaft 5 drives the rotating cylinder 6 to rotate, and the conveying blade 8 on the rotating cylinder 6 is always in close contact with the inner wall of the housing 2 under the joint action of the elastic force of the spring 7, the gravity of the iron sand and the centrifugal force , the end of the conveying blade 8 is in sliding contact with the lower part of the housing 2 and maintains a sliding seal. An independent and airtight single-portion conveying space is formed between two adjacent conve...

Embodiment 3

[0051] A car paint with fast drying speed. The car paint includes a main agent and a curing agent. The raw materials of the main agent and the curing agent are respectively in parts by volume: main agent components: water-based epoxy resin 30-55, Pigment 15-35, anti-rust agent 1-5, anti-corrosion solvent 5-25, mica powder 5-10; curing agent components: ethylene glycol butyl ether 45-85, thickener 45-65; the paint The volume ratio of the component and the curing agent component is 1-4:2.

[0052] A preparation method for automobile paint, the method comprises the following steps:

[0053] A: Preparation of paint components:

[0054] (1) Transport 10-25 parts of water-based epoxy resin, 1-5 parts of anti-rust agent, 5-25 parts of anti-corrosion solvent, and 5-10 parts of mica powder into the mixing tank according to volume parts through a single delivery pump, and stir evenly ;

[0055] (2) Add 15-35 parts of pigment while stirring, and disperse at high speed in the mixing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com