Integrated testing device under multi-field coupling environment

A technology for testing devices and environments, applied to measuring devices, using stable tension/pressure to test the strength of materials, and controlling multiple variables at the same time, it can solve problems such as inability to expand at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

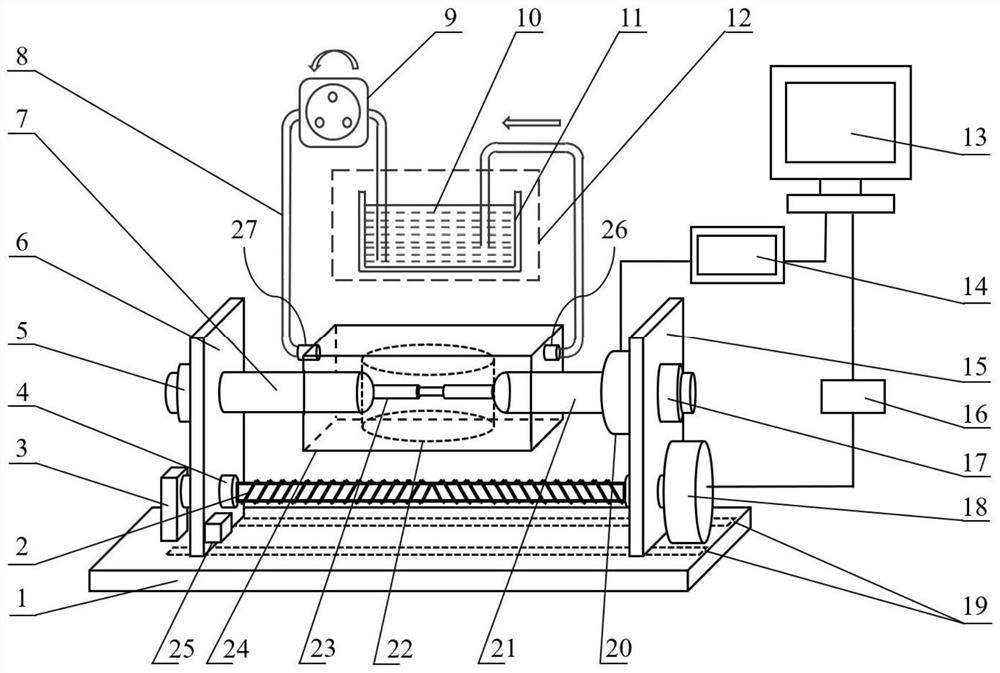

[0033] combine figure 1 In the device shown, the selected sample 23 is a 2000 series aluminum alloy material, the sample is machined into a dumbbell shape, and the gauge length is Φ3*10mm; sample 23 is clamped by the fixture 7 at the left end of the sample and the fixture 21 at the right end of the sample, Fix the left end movable support plate 6 and the right end movable support plate 15 through the left end clamp fixing nut 5 and the right end clamp fixing nut 17; the flow field environment module 24 is not connected to the experimental device, and the sample 23 is directly exposed to room temperature air environment for testing ; The axial tension loading rate of the AC servo motor 18 controlled by the servo drive encoder 16 is 10 -5 mm·s -1 , that is, the strain rate of sample 23 is 10 - 6 the s -1 ; Adopt force sensor 20 to collect the force value that sample 23 is subjected to, and feed back to test control computer 13 in real time through force value digital display...

Embodiment 2

[0035] On the basis of Example 1, connect the flow field environment module 24 to the experimental device, add 3.5% NaCl solution to the flow field environment module 24, and keep the loading rate of the sample 23 consistent with that of Example 1 under the test environment at room temperature. Use the test control computer 13 to draw the force-displacement curve of sample 23 in 3.5% NaCl solution, and compare it with the force-displacement curve of the sample in air in Example 1 to analyze the influence of the corrosive medium on the mechanical behavior of the sample mechanism.

Embodiment 3

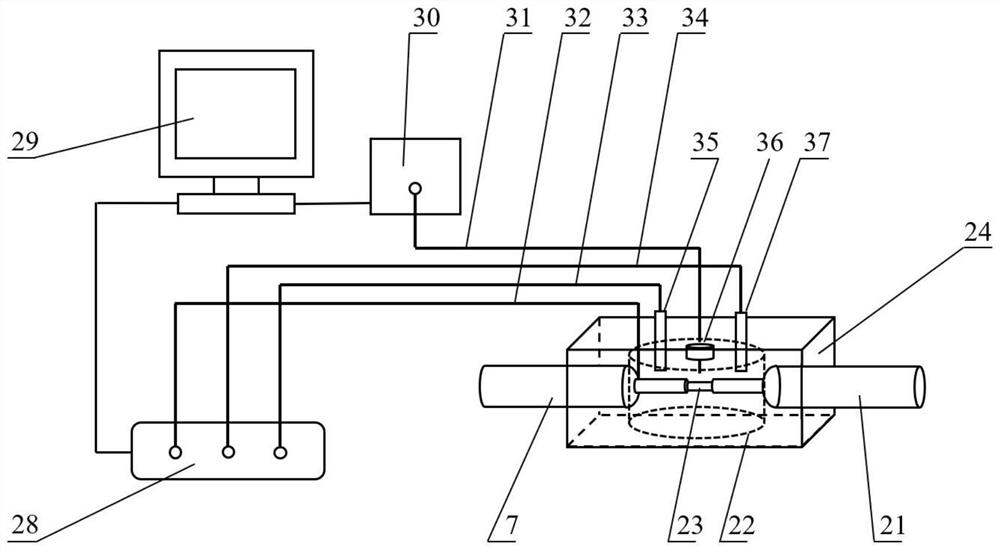

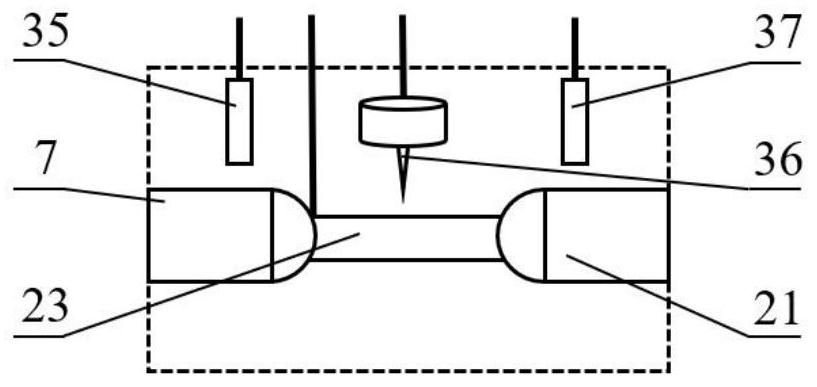

[0037] combine figure 1 In the device shown, the selected sample 23 is AZ31 magnesium alloy material, the sample is machined into a dumbbell shape, and the gauge length is Φ3*10mm; The left end clamp fixing nut 5 and the right end clamp fixing nut 17 are fixed on the left end movable support plate 6 and the right end movable support plate 15; the flow field environment module 24 is connected to the experimental device, the simulated plasma solution is added to the flow field environment module 24, and the temperature The temperature is 37°C; the AC servo motor 18 is controlled by the servo drive encoder 16, and a tensile load is applied to the sample 23, and the tensile load on the sample 23 is adjusted to 282.6N in combination with the force value digital display table 14; figure 2 The device shown is plugged into the figure 1 In the shown device, the working electrode electrode wire 32, the counter electrode electrode wire 33 and the reference electrode electrode wire 34 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com