Reactor core melt grouping catcher

A core melt and trap technology, which is applied in the field of nuclear safety control, can solve the problems of not considering the group capture of core melt, and achieve the effects of effective cooling, increased storage ratio, and minimized release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

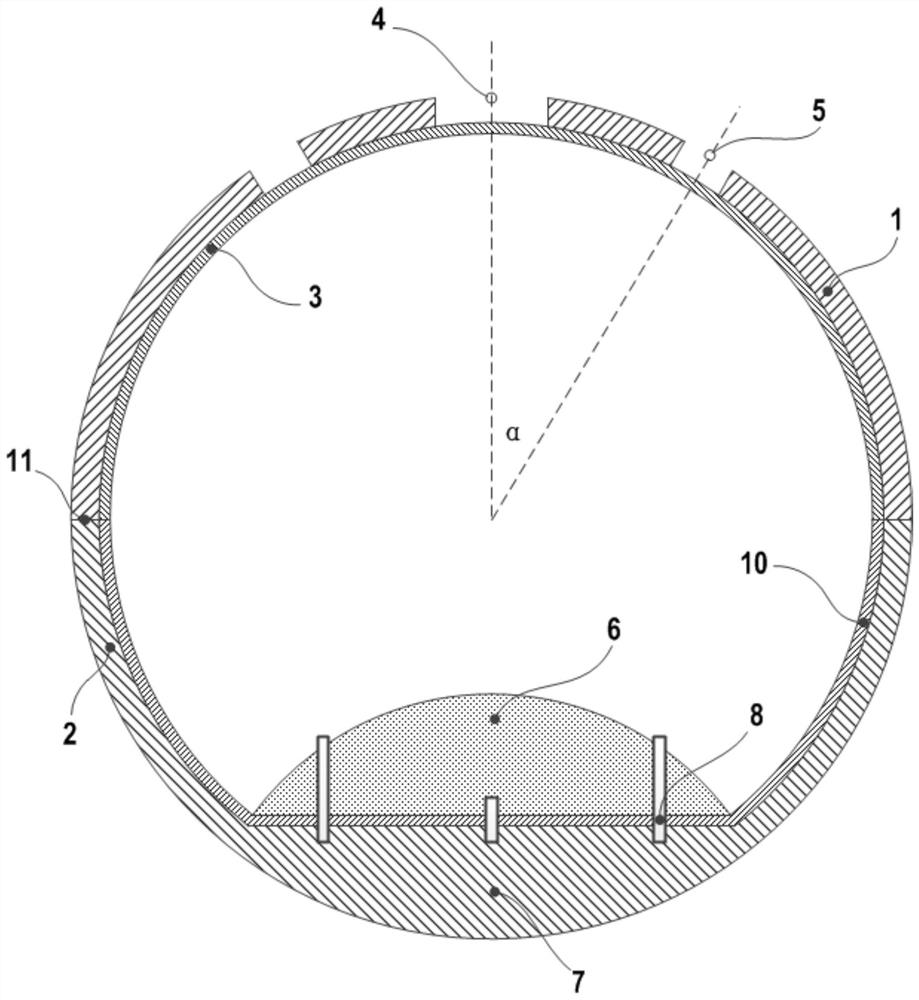

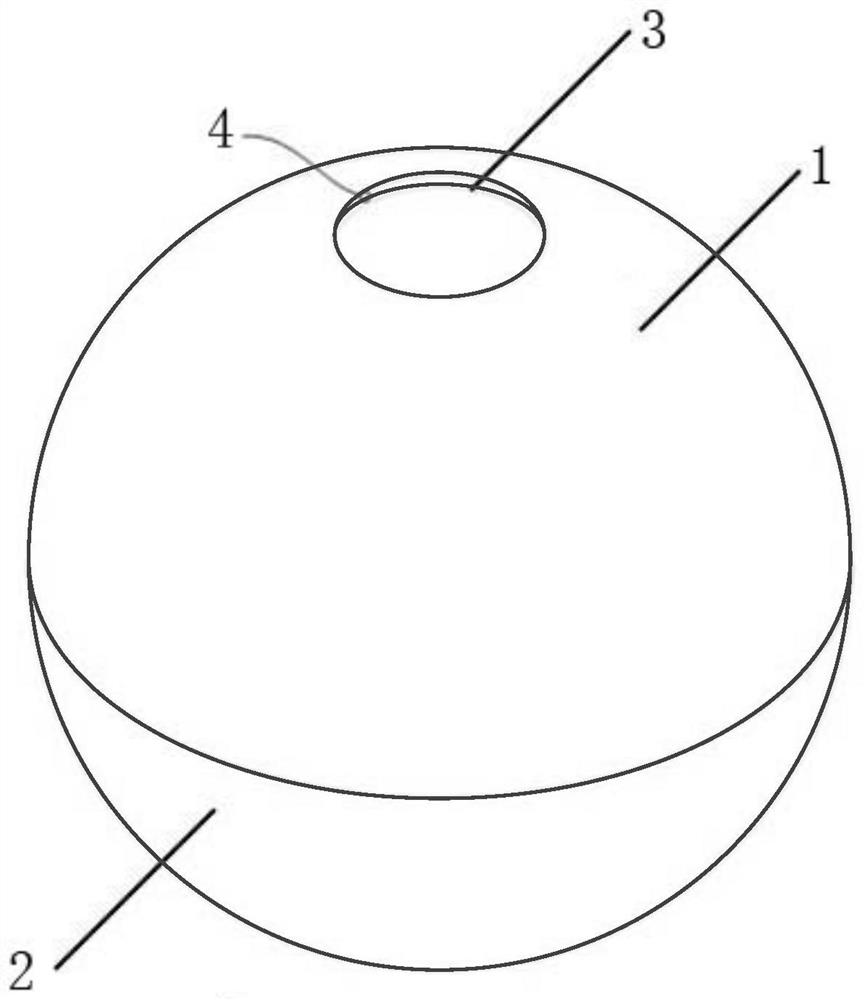

[0026] The structure of the reactor core melt group trap of the exemplary invention is as follows Figure 1-2 As shown, it includes the upper hemisphere 1 of the high-temperature-resistant ceramic shell, the lower hemisphere 2 of the high-temperature-resistant ceramic shell, the upper hemisphere 3 of the metal liner, the main molten material sipping channel 4, the auxiliary molten material sipping channel 5, the inner tank counterweight 6, and the outer shell Counterweight 7, fixing bolt 8, metal liner lower hemisphere 10, screw thread 11.

[0027] The upper hemisphere 1 and the lower hemisphere 2 of the high-temperature-resistant ceramic shell are made of ceramics or ceramic composite materials (here specifically zirconia or SiC) with a melting point not lower than 1800°C, and they are connected together by threads 11 to form Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com