Manufacturing method of low-organosilicone enameled wire

A technology of silicone paint and manufacturing method, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as cross-contamination, inability to effectively control silicone content, and silicone pollution, and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the purpose, structure and function of the present invention, a method for manufacturing a low-organosilicon enameled wire of the present invention will be further described in detail below in conjunction with the accompanying drawings.

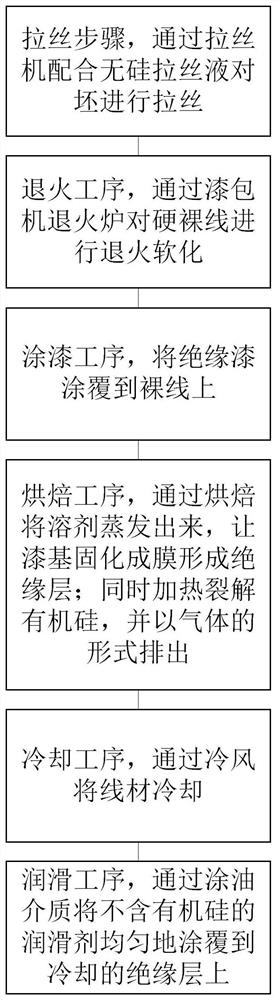

[0025] Such as figure 1 As shown, the low-organosilicon enameled wire manufacturing method of the present invention includes two steps of wire drawing and enamelling.

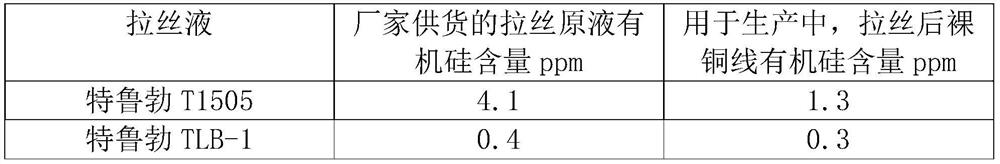

[0026] S1, the wire drawing step, the copper billet is drawn with the wire drawing machine and the wire drawing liquid, and the hard bare copper wire of the required specification is obtained. Specifically, a low-oxygen copper billet with a diameter of 8.0mm is used to obtain a hard bare copper wire with a diameter of 0.060-0.100mm through the processes of large drawing, medium drawing, small drawing, fine drawing, and micro drawing.

[0027] S2, a step of wrapping varnish, wrapping the insulating layer on the bare wire.

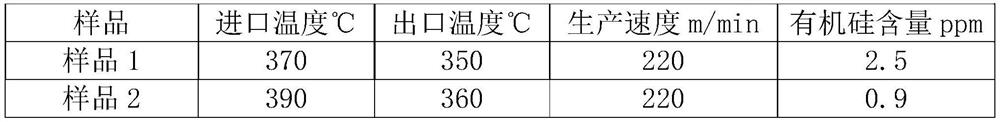

[0028] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com