Graphene-based thermosensitive electrothermal film and forming and curing method

A curing method and electric heating film technology, which is applied in the direction of electric heating devices, electrical components, ohmic resistance heating, etc., can solve the problems that the uniformity and stability of the electric heating film need to be improved, the viscosity is not easy to control, pollute the environment, etc., and achieve rapid heating and effective heating. Heat generation, improved stability, and high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

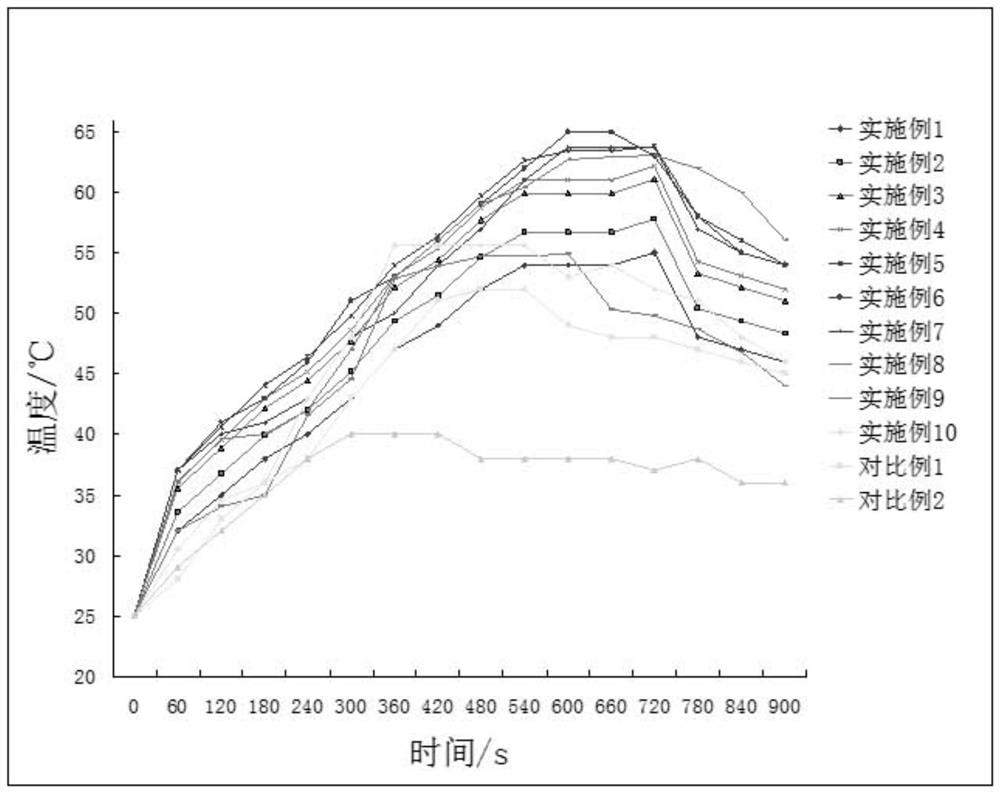

Examples

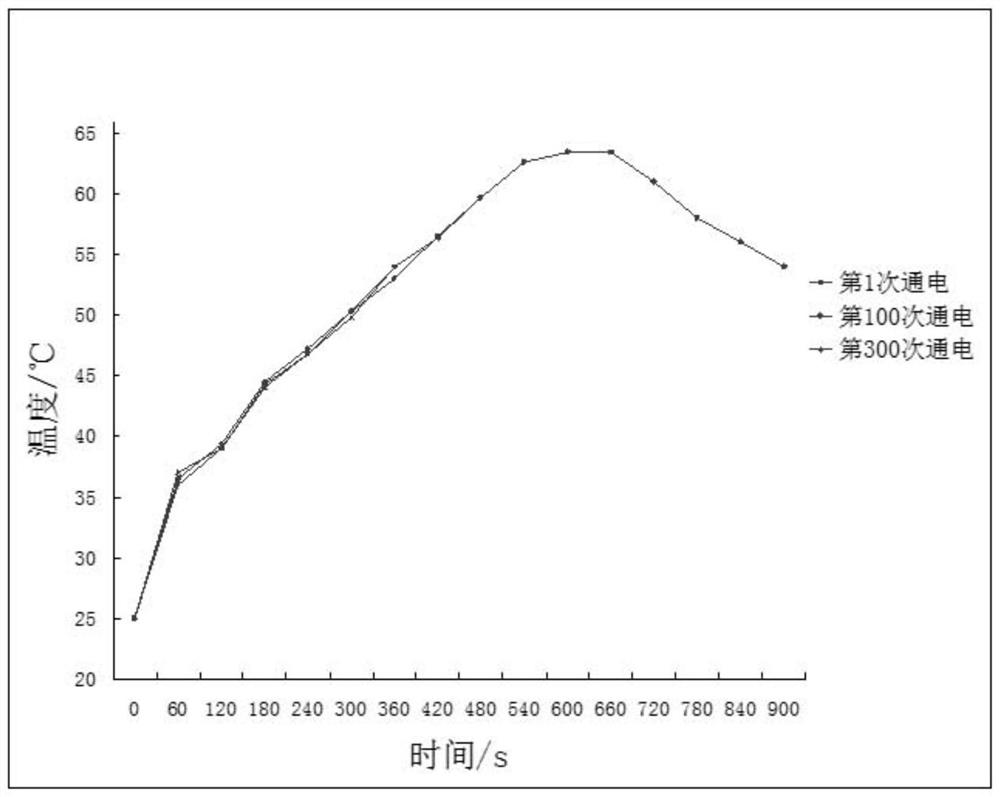

Embodiment 1

[0035] This embodiment discloses a graphene-based thermosensitive electrothermal film and its curing molding method. The coating components and dosage used are shown in Table 1 in detail. The obtained coating of the present invention is mixed with deionized water, wherein the mass ratio of coating and deionized water is 1:1, water-soluble epoxy resin, sodium carboxymethyl cellulose, carbon black, graphene, conductive filler nanoparticles are mixed in Stir at 300rmp for 2min, add an appropriate amount of additives and stir at a constant speed of 500rmp for 10min to prepare a conductive coating, and evenly coat the conductive coating on the glass substrate; the thickness of the coating is about 100μm; the obtained coating is dried in a vacuum oven Bake until the quality remains unchanged, and the baking temperature is 60°C to obtain the target electric heating layer.

[0036] The quality of auxiliary agent sodium lauryl sulfate is 1% of water-soluble epoxy resin quality in the p...

Embodiment 2

[0039] The main difference between this embodiment and embodiment 1 is shown in Table 1;

[0040] In this embodiment, the baking temperature is 70°C.

[0041] The quality of auxiliary agent sodium lauryl sulfate is 2% of water-soluble epoxy resin quality in the present embodiment;

[0042] The mass of sodium alginate is 8% of the mass of water-soluble epoxy resin.

Embodiment 3

[0044] The main difference between this embodiment and embodiment 1 is shown in Table 1;

[0045] In this embodiment, the baking temperature is 80°C.

[0046] The quality of auxiliary agent sodium lauryl sulfate is 3% of water-soluble epoxy resin quality in the present embodiment;

[0047] The mass of sodium alginate is 10% of the mass of water-soluble epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com