Petroleum catalytic cracking reaction kettle

A catalytic cracking and reactor technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve problems such as single function, elongated process, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

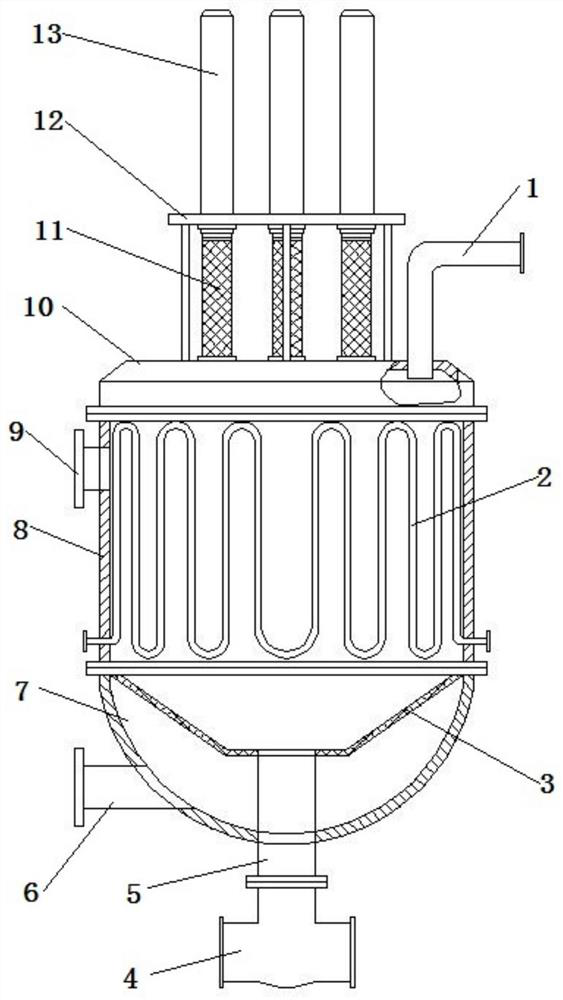

[0026] Such as figure 1 Shown, a kind of petroleum catalytic cracking reactor comprises reactor body, and reactor body comprises cylinder body 8, and cylinder body 8 top is provided with top cover 10, and cylinder body 8 bottom is provided with bottom shell 7, cylinder body 8 and top cover 10 and The bottom shell 7 is connected by a flange. The top cover 10 is provided with a catalyst adding mechanism and an oil-gas conduit 1. The oil-gas conduit 1 is connected to the fractionation equipment. The cylinder body 8 is provided with a petroleum inlet 9 and a heating mechanism. The bottom shell 7 An oil discharge port 6 is arranged on the top, and an oil residue separation mechanism is arranged in the bottom shell 7 , and the slag discharge part of the oil residue separation mechanism is connected with the slag discharge assembly arranged at the bottom of the bottom casing 7 .

[0027] Such as figure 1 , image 3 and Figure 4 As shown, the catalyst adding mechanism includes a s...

Embodiment 2

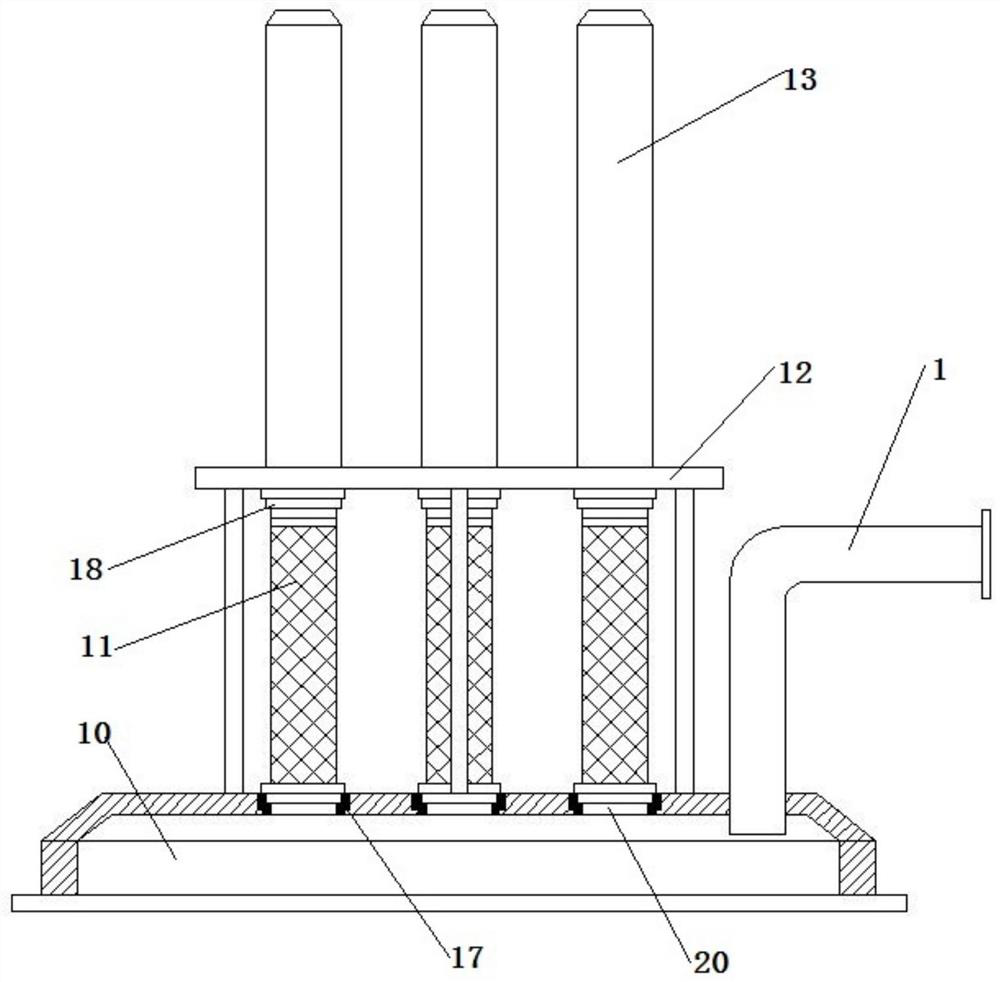

[0034] Such as Figure 5 , Figure 6 As shown, the catalyst adding mechanism comprises a support frame 12, a screw rod 23 and a sliding column 24 are vertically arranged in the support frame 12, a bearing plate 25 is horizontally arranged in the support frame 12, the carrying plate 25 is threadedly connected with the screw rod 23, and the carrying plate 25 is connected with the sliding column 24 Sliding connection, the lower part of the bearing plate 25 is provided with several material net cylinders 11, the upper end of the material net cylinder 11 is threadedly connected with the bearing plate 25, the lower end of the material net cylinder 11 corresponds to the inlet 20 arranged on the top cover 10, and the upper part of the support frame 12 is set The power source 22 is fitted with a turbine 26 on the rotating shaft of the power source 22. The turbine 26 and the screw rod 23 are engaged with each other. Rib 21.

[0035] Such as Figure 6 As shown, a sliding bar is provid...

Embodiment 3

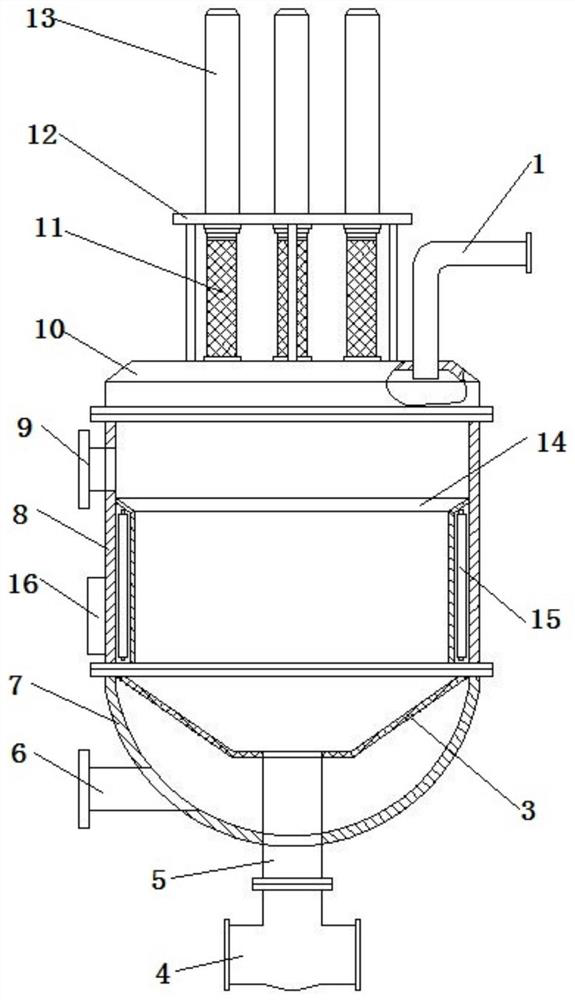

[0039] Such as figure 2 As shown, the heating mechanism includes a heating shell 14 arranged on the inner wall of the cylinder body 8 , a heating pipe 15 is arranged in the heating casing 14 , and the heating pipe 15 is connected to a power supply box 16 arranged on the outer wall of the cylinder body 8 .

[0040] When the present embodiment is in operation, the heating tube 15 is powered and generates heat, and the heating tube 15 transfers heat to the oil in the kettle body through the heating shell 14 to heat the oil.

[0041] Other structures and methods of use are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com