Iron-doped birnessite modification method, modified iron-doped birnessite and application of modified iron-doped birnessite

A birnessite and iron doping technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem that total nitrogen is difficult to meet the discharge standard, cannot be converted into nitrogen, water pollutants, etc. problems, to achieve cost savings, high-efficiency catalytic oxidation capacity, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

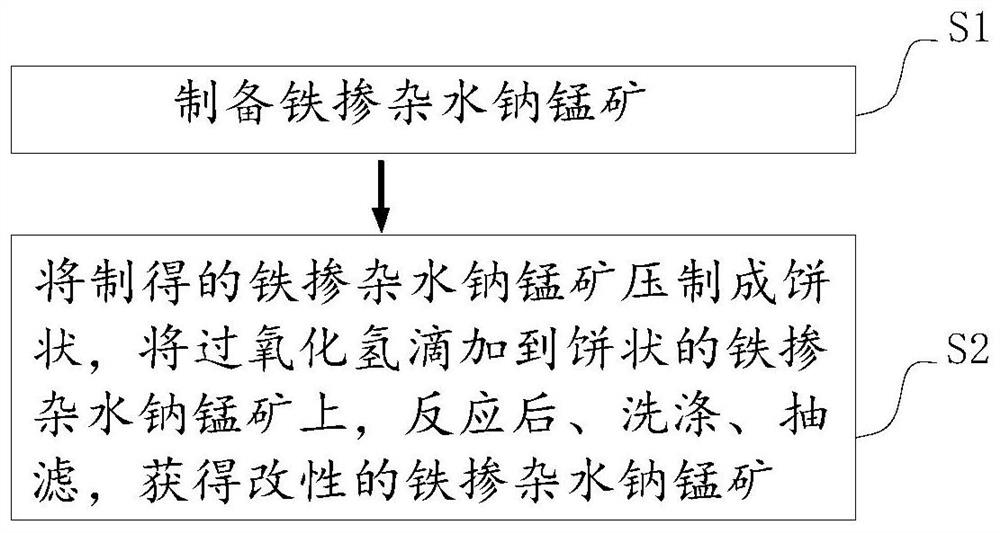

Method used

Image

Examples

Embodiment 1

[0060] Preparation of modified iron-doped birnessite (1):

[0061] Configure 900mL, 0.5mol / L potassium permanganate solution;

[0062] Configure 1L mixed solution containing 0.35mol / L manganese chloride and 0.35mol / L ferrous chloride, and adjust the pH value of the mixed solution to 2 with 1M hydrochloric acid;

[0063] Slowly add the prepared potassium permanganate solution dropwise into the mixed solution of manganese chloride and ferrous chloride. After the dropwise addition, continue to stir for 2 hours. After the dropwise addition, seal the beaker and let it stand for 50 minutes. After the reaction is complete, filter , and washed with deionized water to obtain iron-doped birnessite.

[0064] Weigh 80g of iron-doped birnessite, add 80mL, 30% hydrogen peroxide dropwise to the surface of iron-doped birnessite, during the dropping process, keep stirring, after the dropping, seal for 2h, wash, Filtrate to obtain the modified iron-doped birnessite (1).

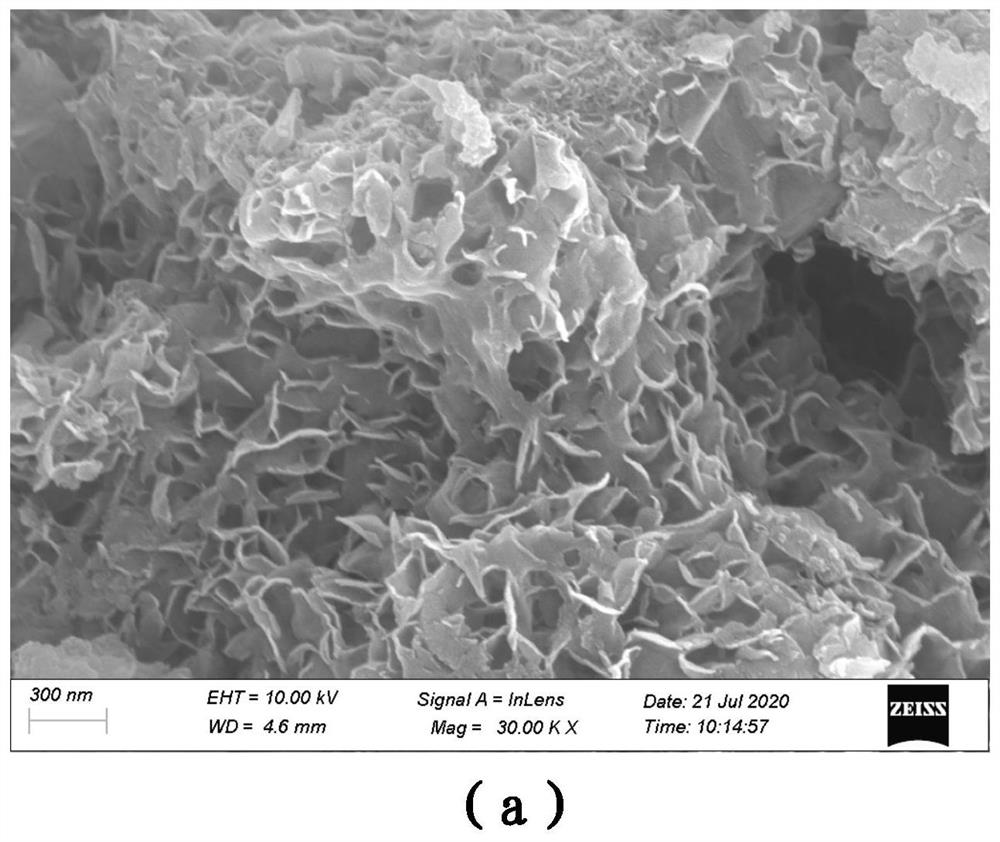

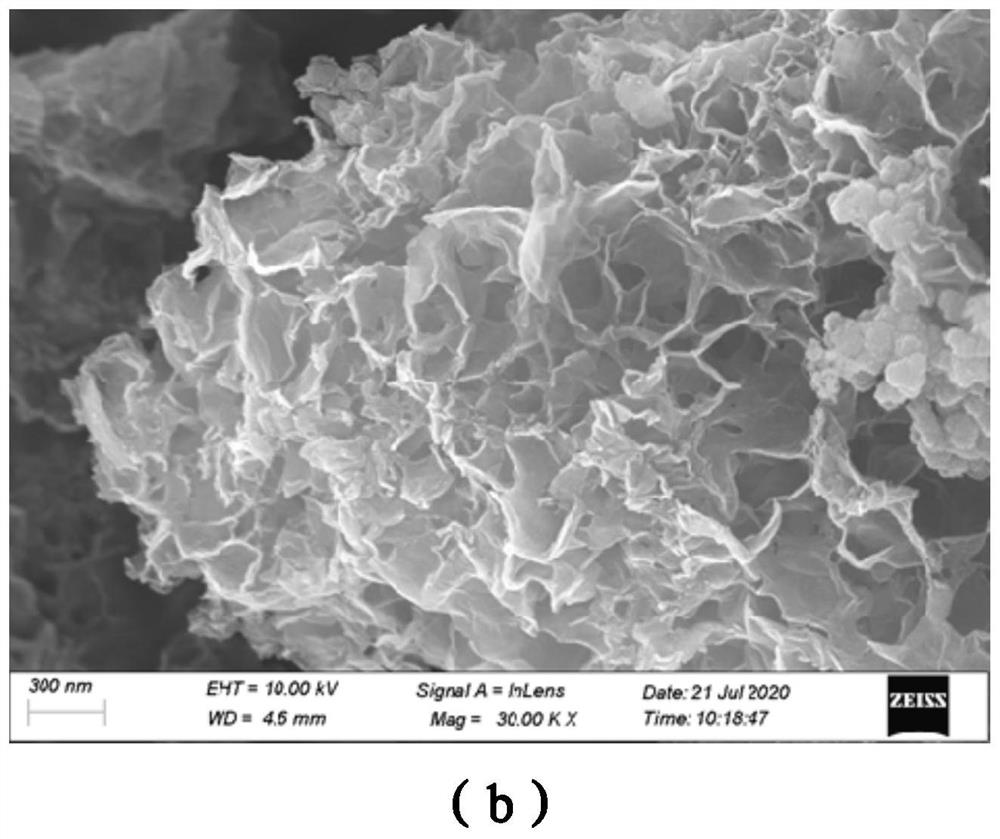

[0065] The obtained...

Embodiment 2

[0076] Preparation of modified iron-doped birnessite (2):

[0077] Configure 900mL, 0.5mol / L potassium permanganate solution;

[0078] Configure 1L mixed solution containing 0.35mol / L manganese chloride and 0.35mol / L ferrous chloride, and adjust the pH value of the mixed solution to 2 with 1M hydrochloric acid;

[0079] While stirring, slowly add the prepared potassium permanganate solution dropwise into the mixed solution of manganese chloride and ferrous chloride. After the dropwise addition, continue to stir for 2 hours. After the dropwise addition, seal the beaker and let it stand for 50 minutes. When complete, filter and wash with deionized water to obtain iron-doped birnessite.

[0080] Weigh 80g of iron-doped birnessite, add 150mL, 30% hydrogen peroxide dropwise to the surface of iron-doped birnessite, during the dropping process, keep stirring, after the dropping, seal for 2h, wash, Filtration to obtain the modified iron-doped birnessite (2).

[0081] The obtained m...

Embodiment 3

[0089] Preparation of modified iron-doped birnessite (3):

[0090] Configure 900mL, 0.5mol / L potassium permanganate solution;

[0091]Configure 1L mixed solution containing 0.35mol / L manganese chloride and 0.35mol / L ferrous chloride, and adjust the pH value of the mixed solution to 2 with 1M hydrochloric acid;

[0092] Slowly add the prepared potassium permanganate solution dropwise into the mixed solution of manganese chloride and ferrous chloride. After the dropwise addition, continue to stir for 2h. After the dropwise addition, seal the beaker and let it stand for 50min. After the reaction is completed, Filtration and washing with deionized water yielded iron-doped birnessite.

[0093] Weigh 80g of iron-doped birnessite, add 200mL, 30% hydrogen peroxide dropwise to the surface of iron-doped birnessite, during the dropping process, keep stirring, after the dropping, seal for 2h, wash, Filtration to obtain the modified iron-doped birnessite (3).

[0094] The obtained modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com