Micronano-structured and graphene based composite visible light catalytic material and preparing method thereof

A catalytic material and graphene-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of enhancing composite photocatalytic materials, accelerating the separation of photogenerated electron pairs, and prolonging the life of active components and other issues, to achieve the effect of simple process, energy saving and environmental protection performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

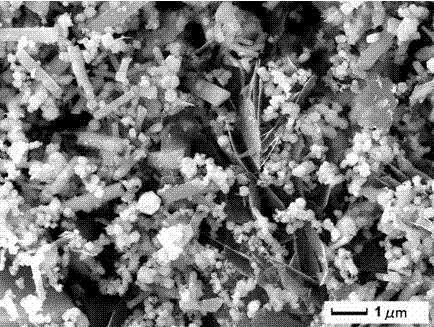

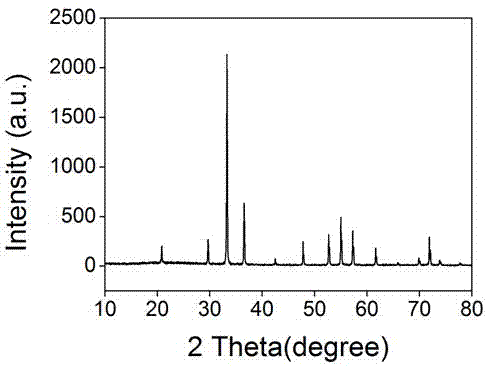

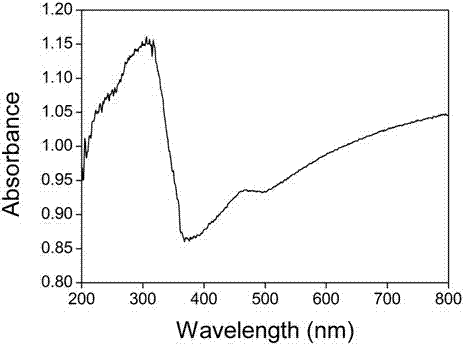

[0026] Disperse 10 mg of graphene oxide in 50 ml of deionized water for 5 hours to obtain a graphene oxide dispersion. Weigh 1.529 g of silver nitrate and 200 mg of ZnO and dissolve in 50 ml of deionized water for 30 minutes and obtain a mixed precursor solution. A. Add the mixed precursor solution A dropwise to the graphene oxide dispersion under magnetic stirring, and continue to stir at 100 rpm for 6 hours at room temperature to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 Dissolve in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution. Add the prepared disodium hydrogen phosphate solution dropwise to the mixed precursor solution B under stirring until the reaction system appears grayish green and turbid. After the addition is complete The mixed solution was continuously stirred at a speed of 200 rpm for 30 minutes and then transferred to a polytetrafluoroethylene liner, and the liner was sealed in a stainless steel hydrothermal reactor...

Embodiment 2

[0028] Disperse 20 mg of graphene oxide in 50 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion. Weigh 1.529 g of silver nitrate and 300 mg of ZnO and dissolve in 50 ml of deionized water for 30 minutes and obtain a mixed precursor solution. A. Add the mixed precursor solution A dropwise to the graphene oxide dispersion under magnetic stirring, and continue to stir at 100 rpm for 8 hours at room temperature to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 Dissolve in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution. Add the prepared disodium hydrogen phosphate solution dropwise to the mixed precursor solution B under stirring until the reaction system appears grayish green and turbid. After the addition is complete The mixed solution was continuously stirred at a speed of 200 revolutions / min for 40 minutes and then transferred to a polytetrafluoroethylene liner, and the liner was sealed in a stainless s...

Embodiment 3

[0030] Disperse 50 mg of graphene oxide in 50 ml of deionized water by sonicating for 5 hours to obtain a graphene oxide dispersion. Weigh 1.529 g of silver nitrate and 400 mg of ZnO and dissolve in 50 ml of deionized water for 30 minutes and obtain a mixed precursor solution. A. Add the mixed precursor solution A dropwise to the graphene oxide dispersion under magnetic stirring, and continue to stir at 100 rpm for 10 hours at room temperature to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 Dissolve in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution. Add the prepared disodium hydrogen phosphate solution dropwise to the mixed precursor solution B under stirring until the reaction system appears grayish green and turbid. After the addition is complete The mixed solution was continuously stirred at a speed of 200 revolutions / min for 50 minutes and then transferred to a polytetrafluoroethylene liner, and the liner was sealed in a stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com