Degradable packaging material, packaging film bag and preparation method

A packaging material and packaging film technology, applied in the field of highly transparent and degradable packaging materials, can solve the problem of not having the function of keeping fruits and vegetables fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

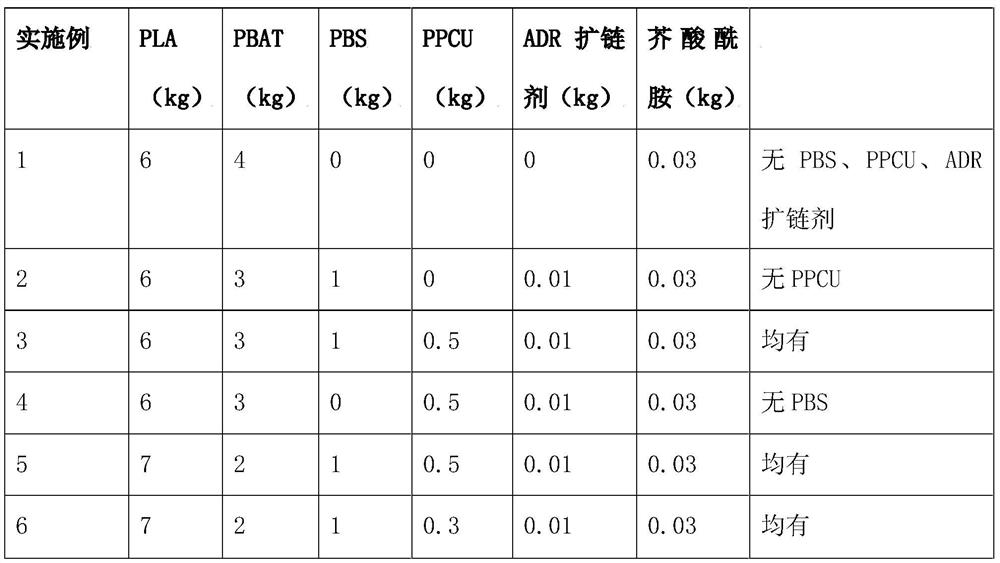

Embodiment 1

[0029] Step 1, preparation of modified materials

[0030] Weigh 6kg of PLA, 4kg of PBAT, 0.01kg of ADR chain extender, and 0.03kg of erucamide, add them into a mixer for thorough mixing, and then add them into a twin-screw extruder to extrude at a temperature of 230°C for granulation.

[0031] Step 2, transparent film preparation

[0032] After the granulation is completed, the modified material prepared in step 1 is dried at 70° C. for 6 hours, and put into an extruder by blowing film to obtain a transparent film with a thickness of 8 um.

Embodiment 2

[0034] Step 1, preparation of modified materials

[0035] Weigh 6kg of PLA, 3kg of PBAT, 1kg of PBS, 0.01kg of ADR chain extender, and 0.03kg of erucamide, add them into a mixer for thorough mixing, and then add them into a twin-screw extruder to extrude at 230°C for granulation.

[0036] Step 2, transparent film preparation

[0037] After the granulation is completed, the modified material prepared in step 1 is dried at 70° C. for 6 hours, and put into an extruder by blowing film to obtain a transparent film with a thickness of 8 um.

Embodiment 3

[0039] Step 1, preparation of modified materials

[0040] Weigh 6kg of PLA, 3kg of PBAT, 1kg of PBS, 0.5kg of PPCU, 0.01kg of ADR chain extender, and 0.03kg of erucamide, add them into a mixer for thorough mixing, then add them into a twin-screw extruder to extrude at a temperature of 230°C out of granulation.

[0041] Step 2, transparent film preparation

[0042] After the granulation is completed, the modified material prepared in step 1 is dried at 70° C. for 6 hours, and put into an extruder by blowing film to obtain a transparent film with a thickness of 8 um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com