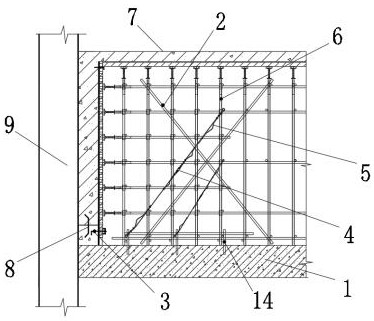

Erecting construction method for basement outer wall pre-counter-pull bent frame single-side formwork supporting system

A technology for basement exterior walls and single-sided formwork, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connectors, building components, etc. Inconvenient leakage, external wall seepage and other problems, to achieve the effect of novel construction technology, convenient operation, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

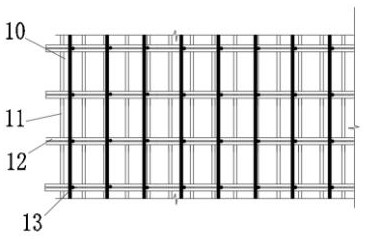

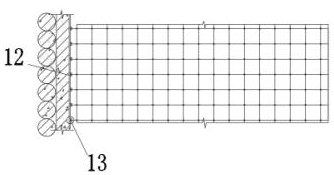

[0046] Embodiment 1: The construction method of the one-side formwork system of the pre-reverse pull-bent frame of the basement exterior wall includes the following steps:

[0047] Step 1: Before erecting the formwork system, bind the outer basement external wall steel bars, and fix the outer steel bars with fulcrums to prevent overturning;

[0048] Step 2: After the inner steel bars are bound and accepted, the single-side formwork system can be erected;

[0049] Step 3: Before setting up the formwork system, set up a 300×3mm water-stop steel plate 8 at the end of the single-side formwork system, that is, at the junction with the double-side formwork, 150mm on each side, to prevent the single-side formwork from affecting the adjacent The pouring of the wall (since the single-side formwork system is only part of the wall, the remaining parts with operating space still use double-side formwork);

[0050] Step 4: At the same time, the single-side formwork must be disconnected fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com