Wellhead sealing simulation device for high-pressure gas well

A simulation device and high-pressure gas technology, applied in sealing/isolation, wellbore/well components, measurement, etc., can solve the problems of no early warning system, lack of pressure feedback sealing adaptive adjustment system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

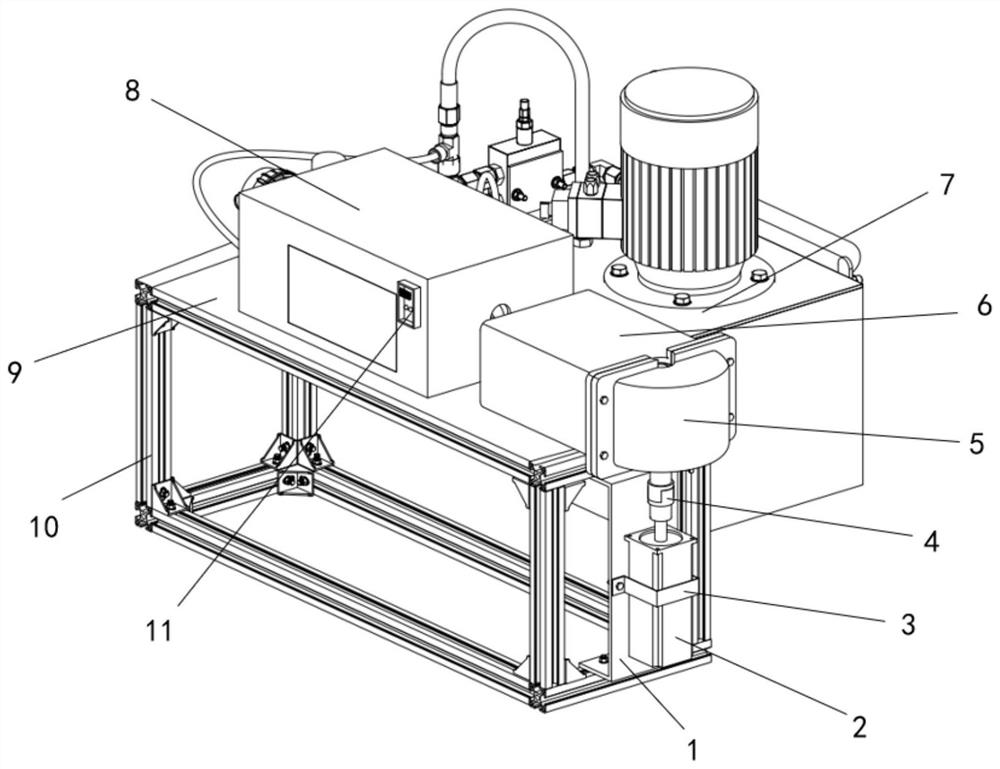

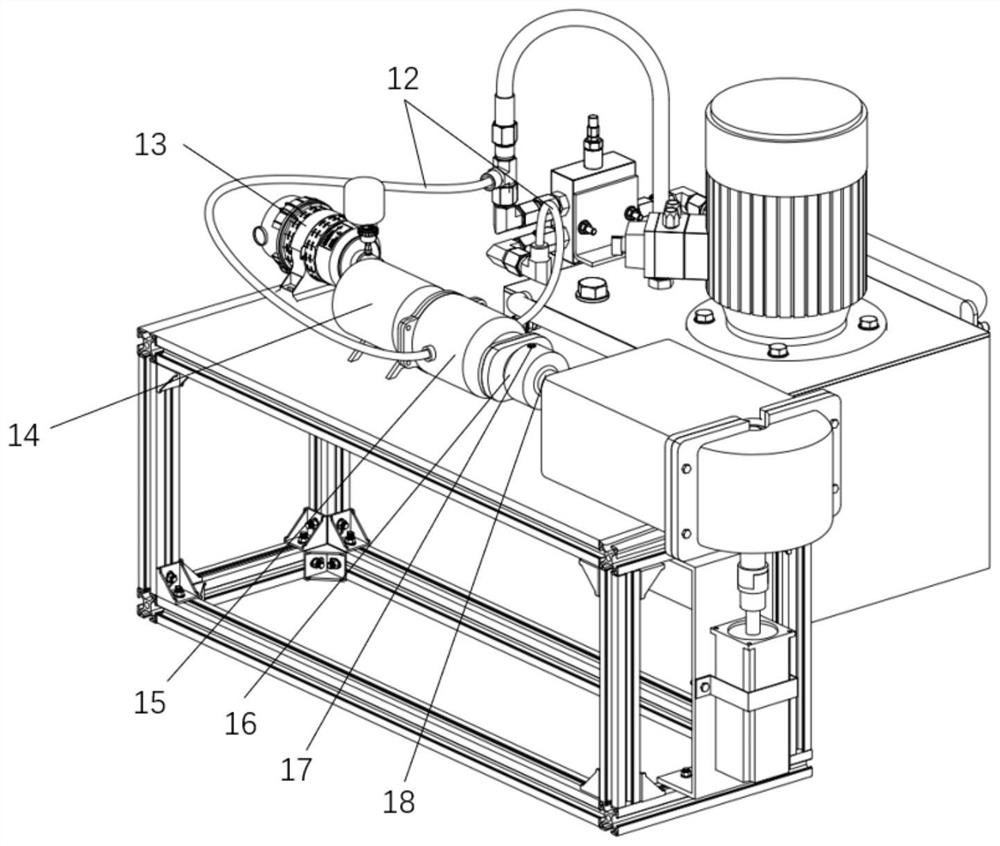

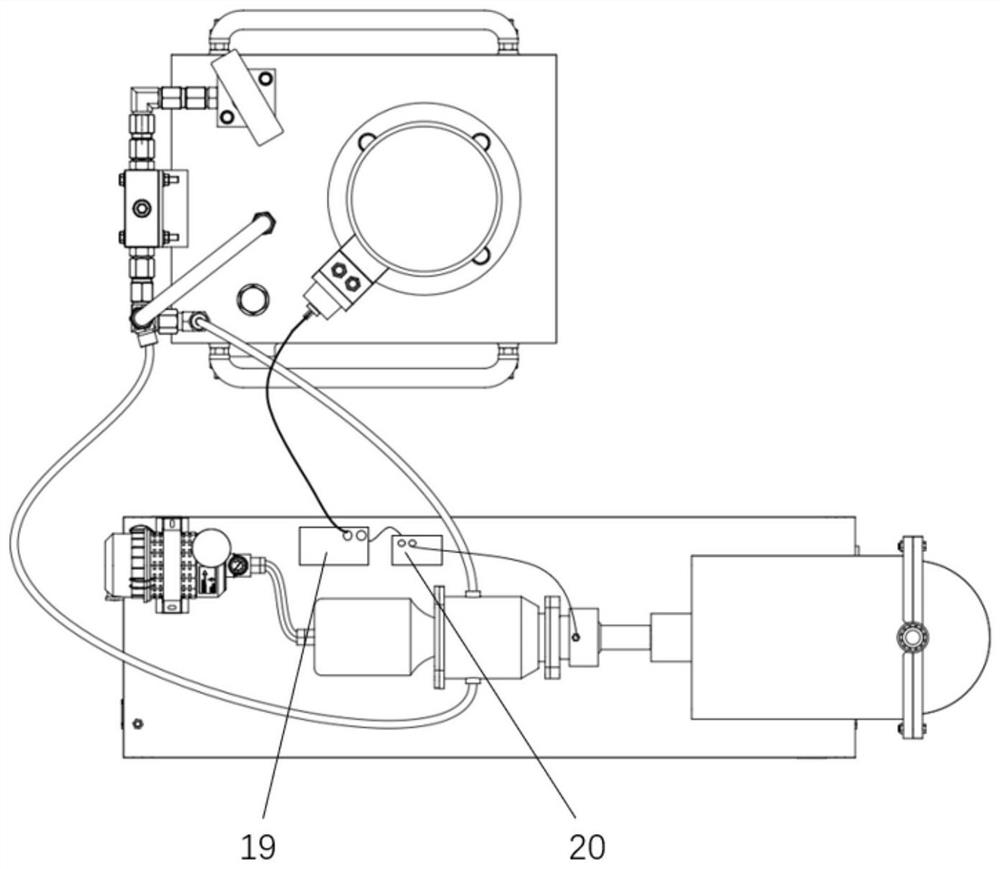

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] Such as Figure 1 to Figure 7 As shown, this high-pressure gas well wellhead sealing simulation device includes a power system, a feedback control unit and a gas leakage detection unit. The power system includes a motor 2 , a crankshaft linkage mechanism, a simulated pipe string 18 and a blowout preventer 15 . The gas leakage detection unit includes a gas storage tank 14 , a gas booster 13 , a gas detection sensor 17 and an alarm 11 . The feedback control unit includes not only the gas detection sensor 17, but also a signal converter, a controller for controlling the loading of the hydraulic pump, and a small hydraulic station 7 for providing load to the blowout preventer.

[0023] The motor is placed on the motor support 1 and fixed on the motor support with the motor mounting flange 3 . The shaft coupling 4 connects the motor and the crankshaft 31 of the cranksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com