Internal combustion engine in-cylinder braking device

A technology of braking device and internal combustion engine, which is applied in valve device, engine control, machine/engine, etc., can solve the problems of not considering valve clearance adjustment, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

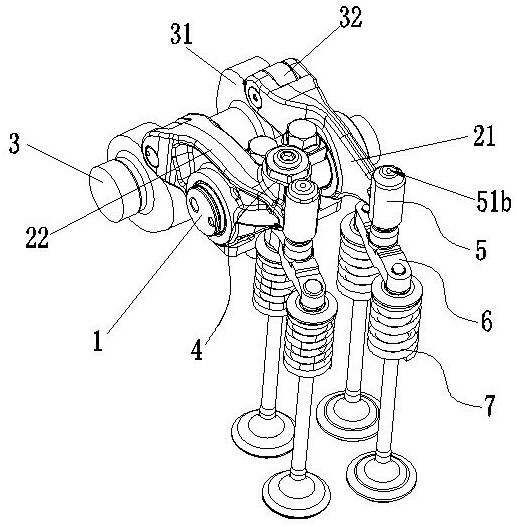

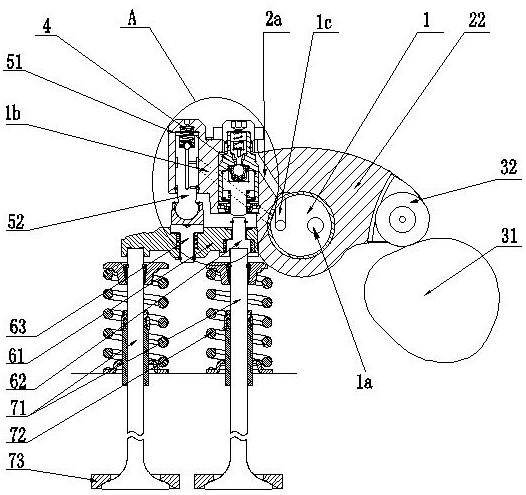

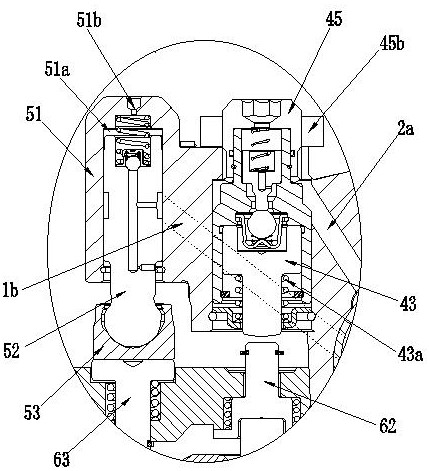

[0034] Embodiment one, such as Figure 1 to Figure 7 As shown, an internal combustion engine in-cylinder braking device includes a rocker shaft 1, and the rocker shaft 1 is equipped with an intake rocker assembly 21 and an exhaust rocker assembly 22, and the intake rocker The assembly 21 and the exhaust rocker assembly 22 are respectively provided with a roller assembly 32 which is matched with the cam 31 on the camshaft 3, and the exhaust rocker assembly 22 is provided with a brake valve assembly 4. The valve ends of the air rocker arm assembly 21 and the exhaust rocker arm assembly 22 are respectively provided with a hydraulic tappet assembly 5, and the hydraulic tappet assembly 5 cooperates with the valve bridge assembly 6, and the valve bridge assembly 6 includes a valve Bridge 61, the valve bridge 61 matched with the exhaust rocker arm assembly 22 is provided with a push rod 62 elastically connected to the valve bridge 61, the push rod 62 is matched with the brake valve a...

Embodiment 2

[0050] Embodiment two, such as Figure 8 and Figure 9 As shown, the structure of the internal combustion engine in-cylinder braking device in this embodiment is similar to that in Embodiment 1, the difference is that in this embodiment, the valve bridge assembly 6 is a non-compensated valve bridge assembly, and the valve bridge assembly 6 There is no need to set the limit pin shaft 63 in the middle. In this embodiment, the exhaust cam profile does not compensate for the initial clearance of the valve.

[0051] working principle:

[0052] Under normal operating conditions of the internal combustion engine:

[0053] The intake rocker arm assembly 21, the exhaust rocker arm assembly 22 and the valves operate in a normal state.

[0054] Under the action of the exhaust cam, the exhaust rocker arm assembly 22 runs according to the profile track of the exhaust cam, and the hydraulic tappet assembly 5 is under the action of the third elastic member 55, and the tappet 52 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com