Strong Constraint Method and Temperature Control System for Temperature Crack Control of Hydraulic Tunnel Lining Concrete

A technology for concrete temperature and hydraulic tunnels, applied in design optimization/simulation, calculation, computer-aided design, etc., can solve the problems that do not reflect concrete strength, surrounding rock performance, lining thickness and structural scale, cannot effectively achieve temperature crack control goals, The finite element method takes a lot of time and costs to achieve the effect of effective temperature control and crack prevention, high degree of automation, and small calculation error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

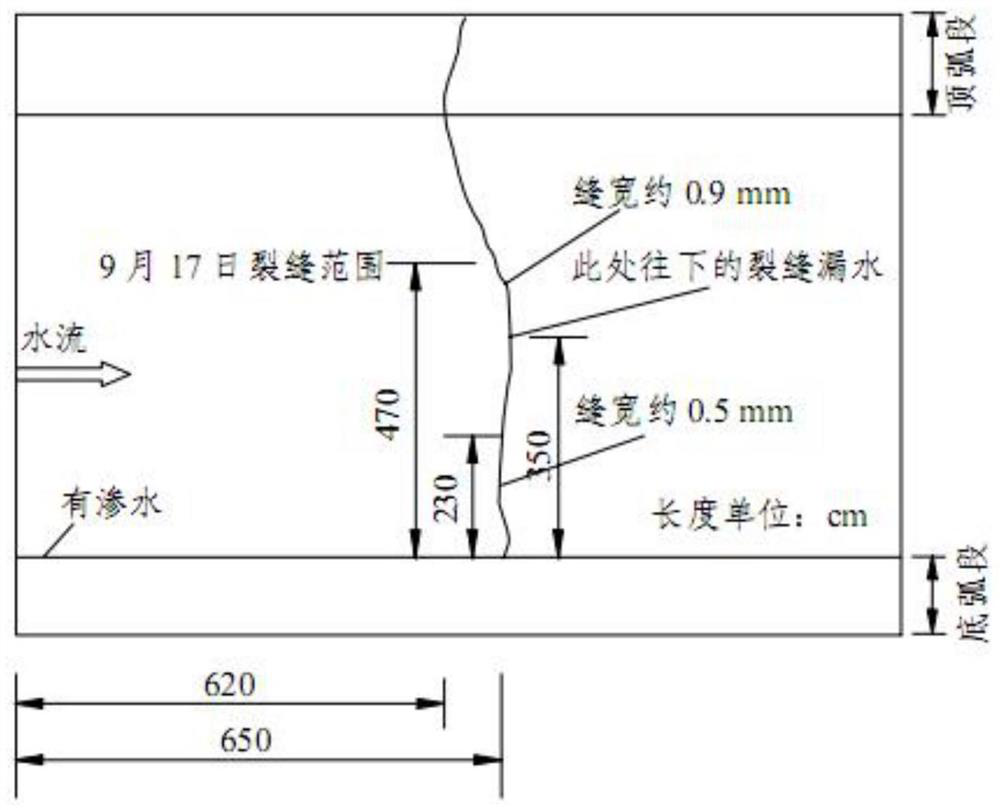

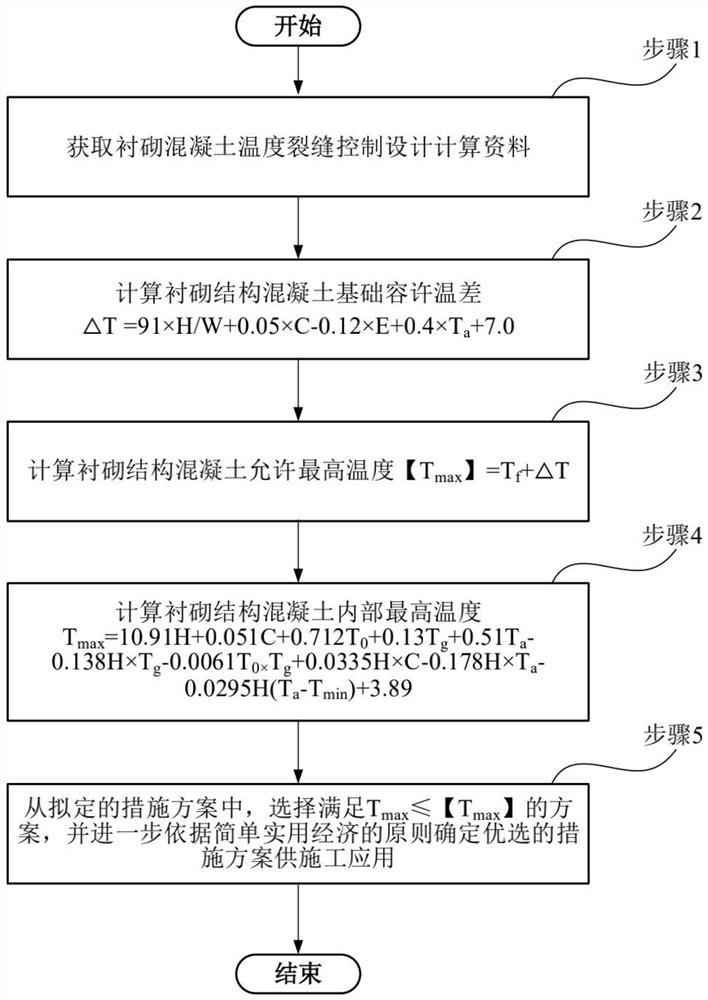

[0100] Hereinafter, in conjunction with the accompanying drawings, taking the concrete lining structure at different parts of the flood discharge tunnel project of Baihetan Hydropower Station as an example, the specific implementation scheme of the strong constraint method for controlling the temperature cracks of the lining concrete of the hydraulic tunnel and the temperature control system involved in the present invention will be described in detail.

[0101]

[0102] Baihetan Hydropower Station has an installed capacity of 16,000MW and is the second largest hydropower station in the world (after the Three Gorges). The hub project is composed of main buildings such as barrage, flood discharge and energy dissipation buildings and water diversion power generation system. The flood discharge facilities include 6 surface holes of the dam, 7 deep holes and 3 flood discharge tunnels on the left bank. The three flood discharge tunnels are arranged on the left bank, adopting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com