A computer vision-based intelligent loading system for brick stacks and a loading method thereof

A computer vision and brick stacking technology, applied in the field of brick stacking transportation, can solve problems such as affecting the safety and health of workers, reducing brick production efficiency, and high labor intensity, saving loading time, reducing loading costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

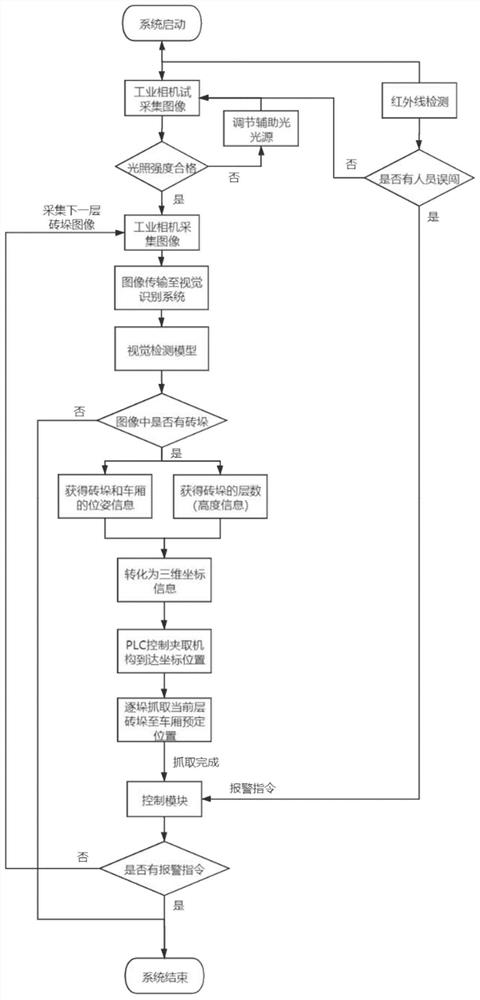

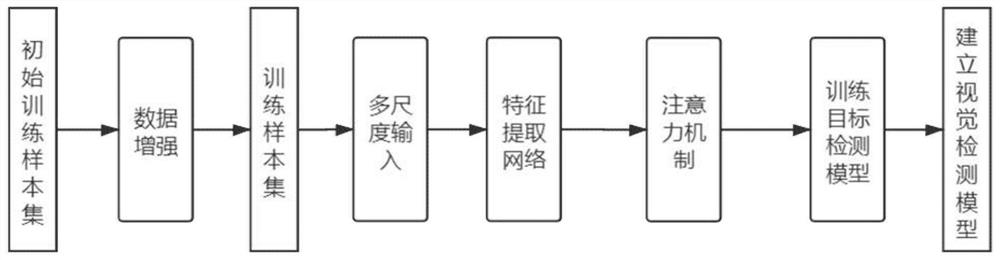

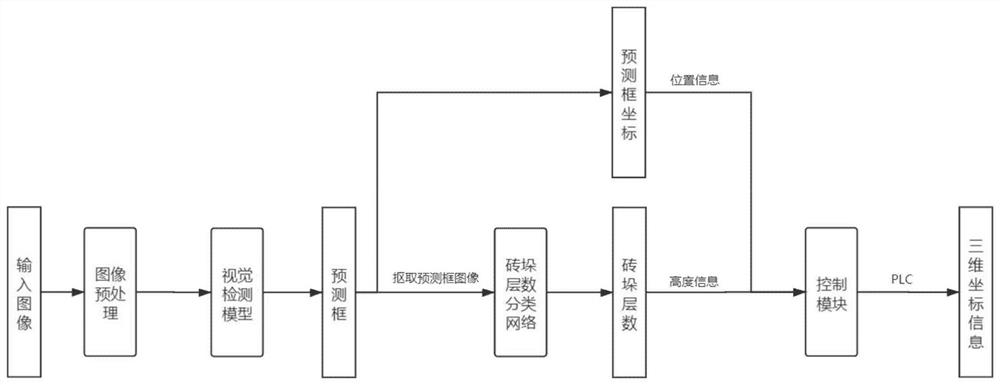

[0041] In order to facilitate the understanding of the present application, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described embodiments are some embodiments of the present invention, but not all embodiments, and should not be construed as limiting the present invention.

[0042] Such as Figure 4 As shown, a computer vision-based intelligent loading system for brick stacks. In a preferred embodiment, the auxiliary light source 1 is 6.5 meters above the ground, which can be a high-brightness LED light source board with a size of 400cm*300cm; an industrial camera 2 The height from the ground is 6.2 meters, which can be a color industrial camera with a resolution of 20 million pixels; the transmission mechanism 3 is 4.8 meters from the ground, and can be a horizontal cylinder driven by a stepping motor with a speed of 0.5m / s; the lifting mechanism 4 It can be a vertical cylinder driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com