Device and method for separating materials with different degrees of flowability

A technology of fluidity and equipment, which is applied in the direction of manufacturing tools, bone cleaning devices, presses, etc., to achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

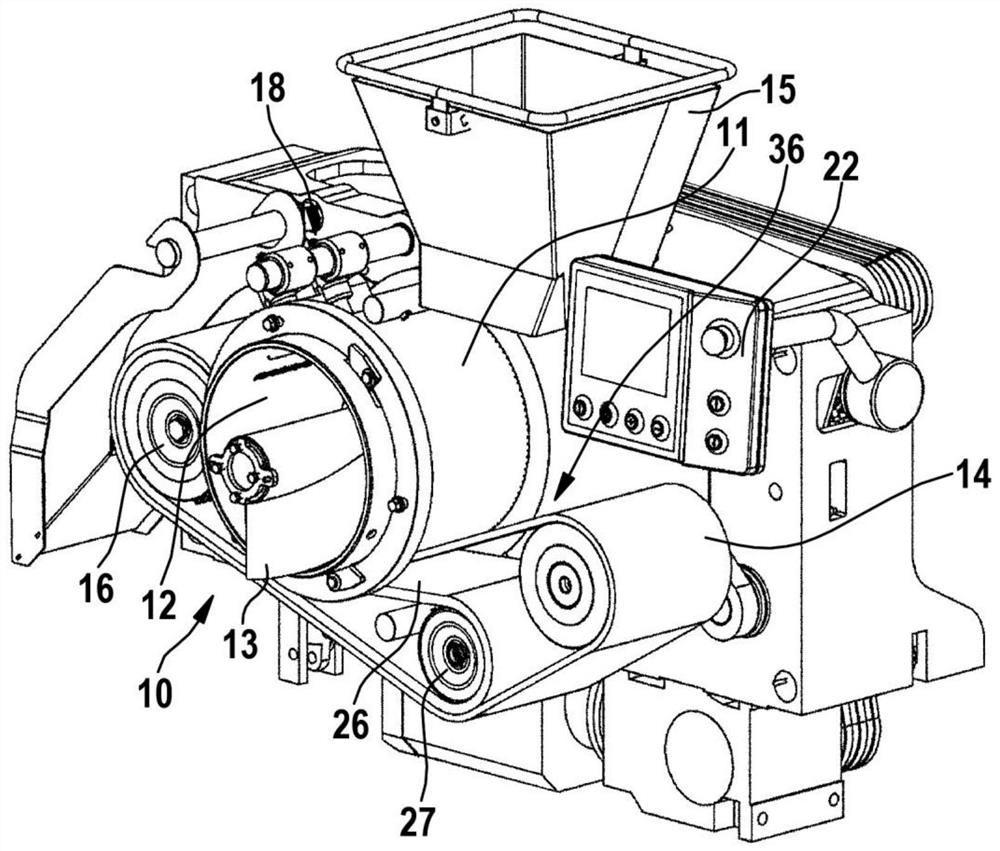

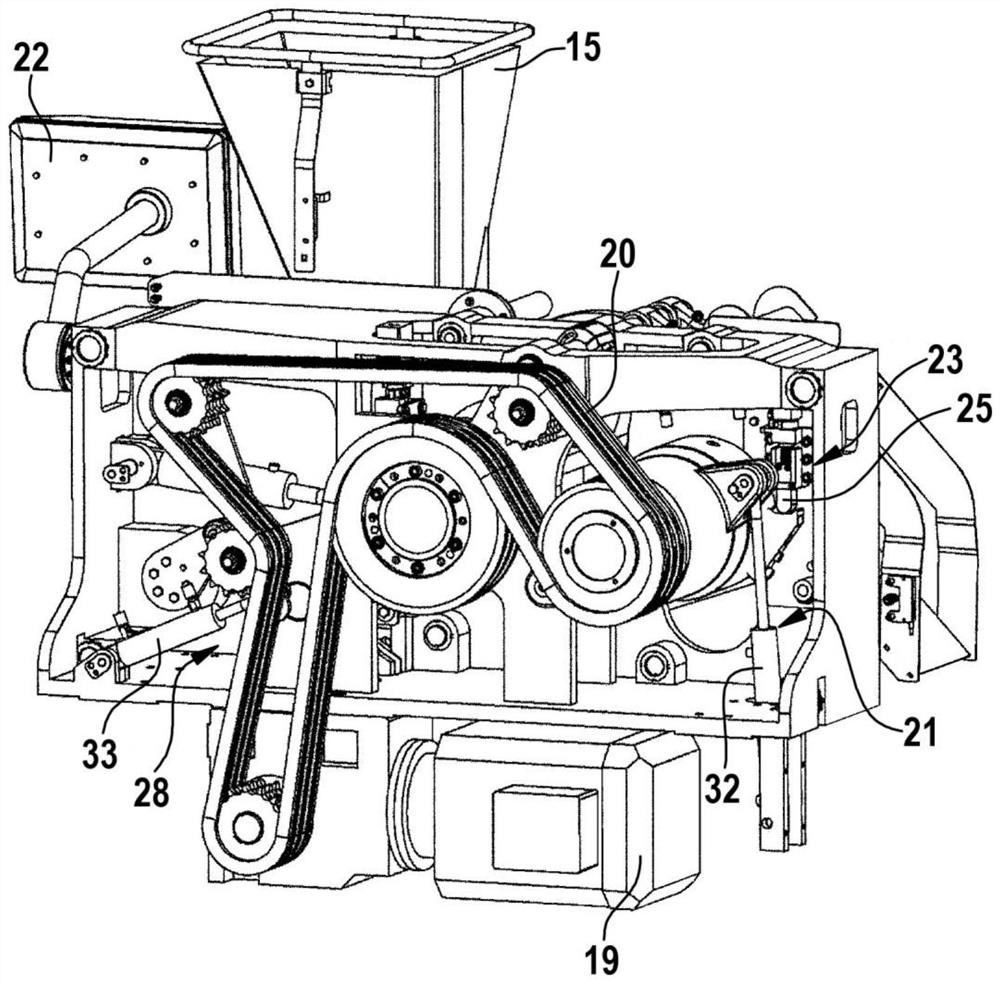

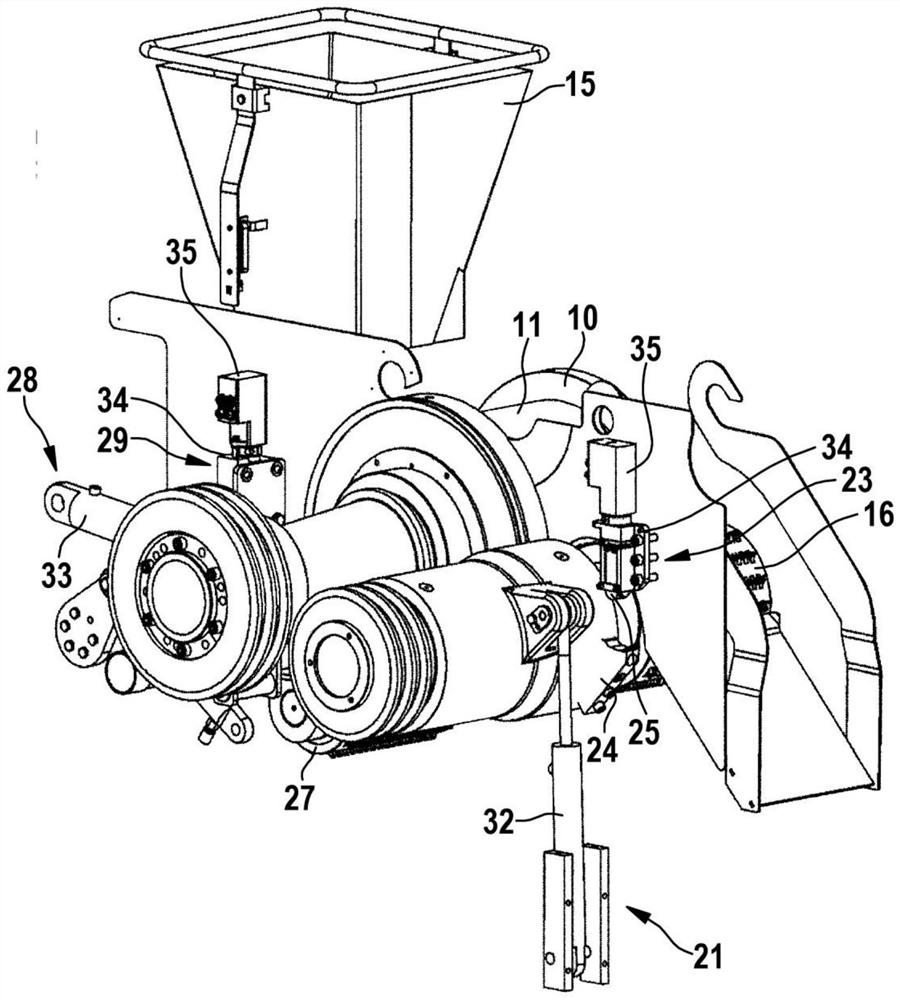

[0036]The device according to the invention and the method according to the invention will be described in more detail below. figure 1 and figure 2 A perspective view of the device according to the invention is shown from the front and from the rear, respectively. The device comprises a rotationally driven hollow drum 10 with a perforated outer peripheral surface 11 . For the sake of clarity, the perforations are not shown in the figures. The perforation of the peripheral surface 11 preferably consists of a plurality of holes distributed over the entire peripheral surface 11 .

[0037] The interior of the hollow drum 10 has an inner cavity 12 from which the part of the material to be pressed pressed through the perforations of the outer peripheral surface 11 is guided to the outside by means of guide elements 13 . A stripping device 18 is arranged in the region of the outer peripheral surface 11 for stripping the material to be pressed on the hollow cylinder 10 . The dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com