Hygienic flange-type tube joint thermal expansion area for gasket

A technology of flange joints and gaskets, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of polluted system, reduced sealing performance of the boundary interface of holes, and the system cannot meet the required fluid velocity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

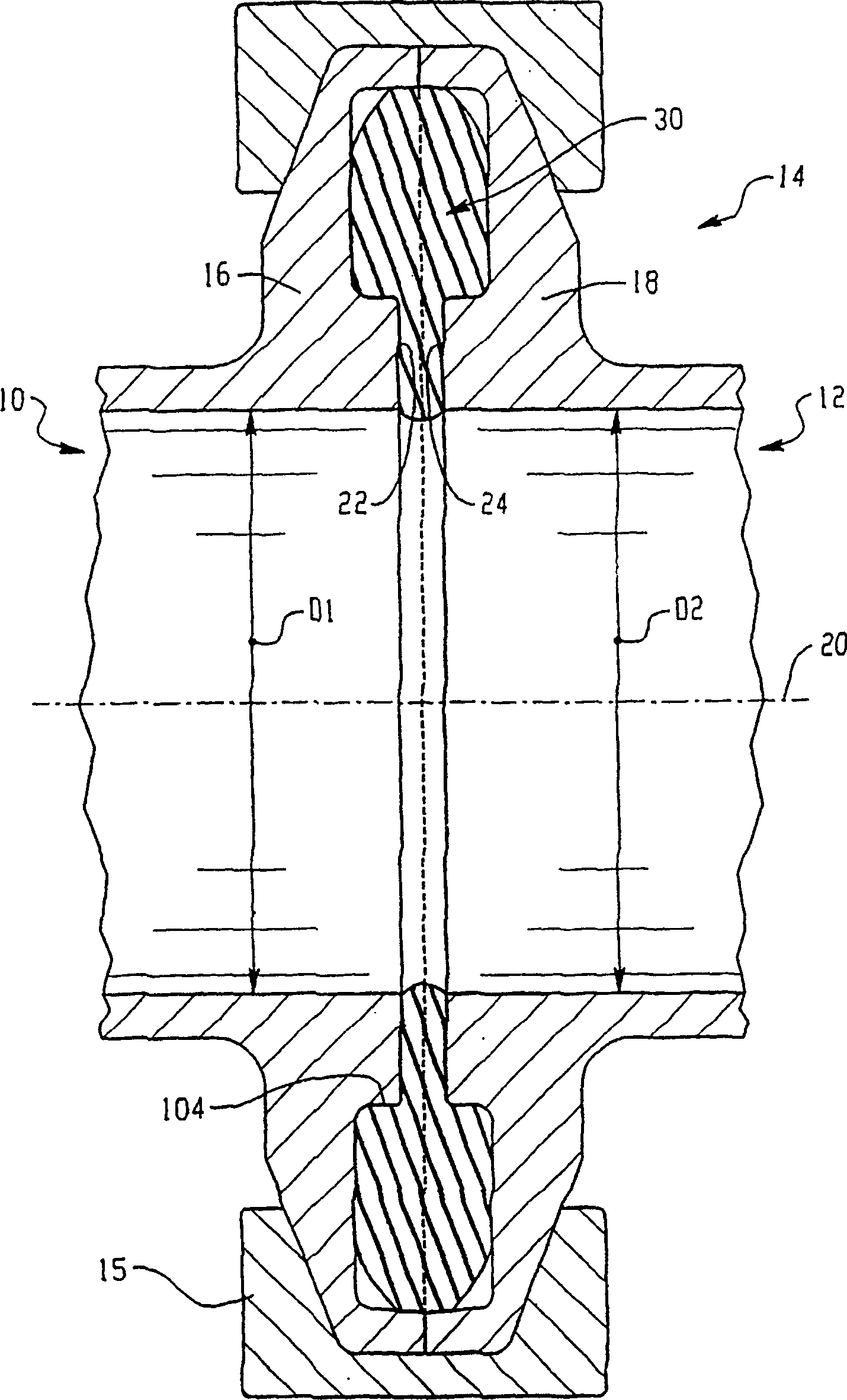

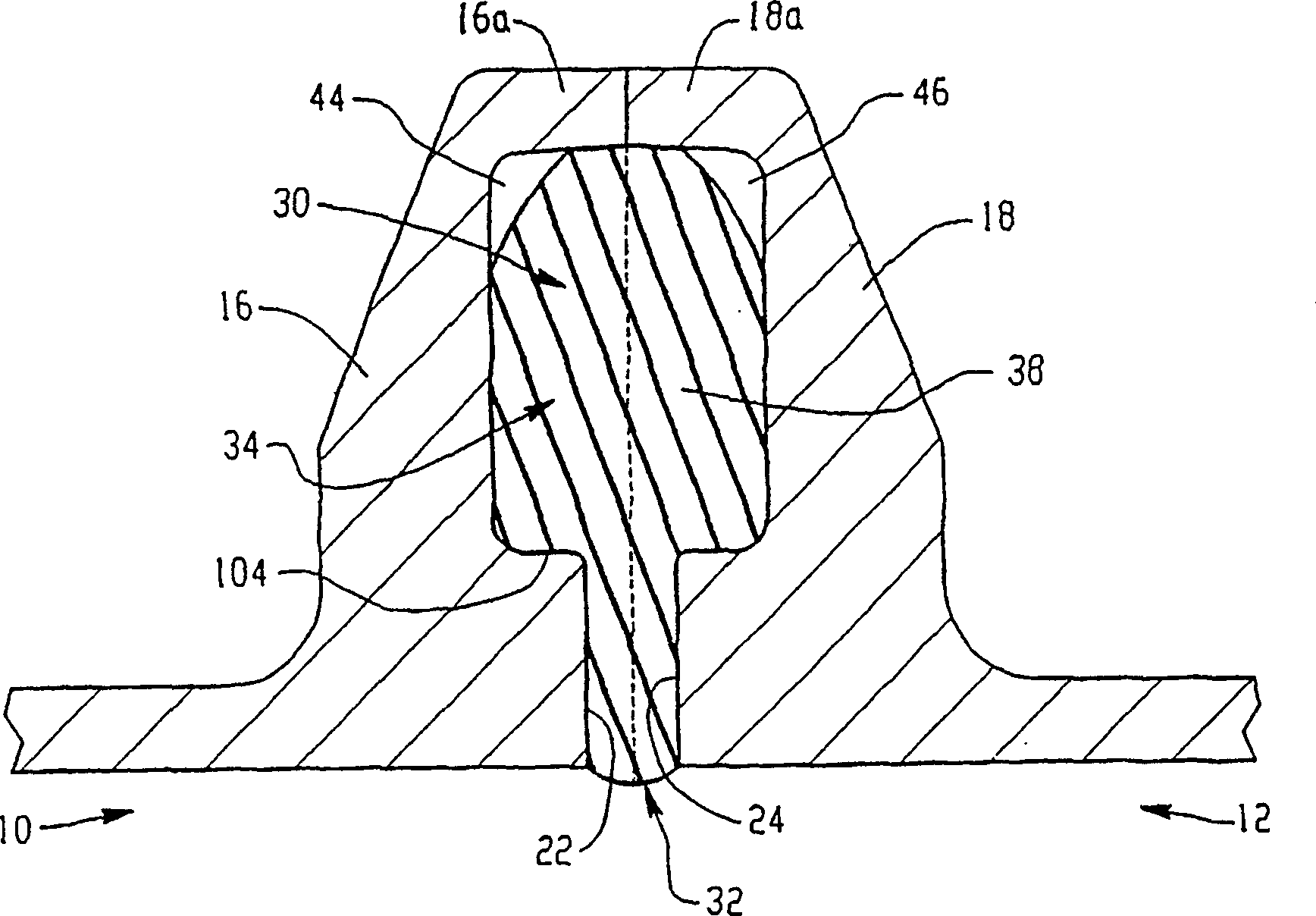

[0026] Referring now to the accompanying drawings, these figures are only used to illustrate preferred embodiments of the present invention, without limiting the meaning of the present invention, figure 1 A pair of axially aligned cylindrical tubes or tube ends 10 , 12 are shown joined together in sealed form by a flanged coupling assembly 14 . The tube ends 10 , 12 each have a uniform open inner diameter D1 , D2 , which have the same inner diameter and are arranged aligned close to each other. An annular continuous radially extending flange 16 , 18 is formed on each pipe end 10 , 12 . This flange enables the two pipe ends to be clamped into assembled condition by conventional clamping rings 15 , which clamps are only schematically shown in the figures. While the flanges 16,18 could be formed as separate components and attached to the pipe ends by suitable means, in this embodiment they are shown integrally formed on the respective pipe ends 10,12.

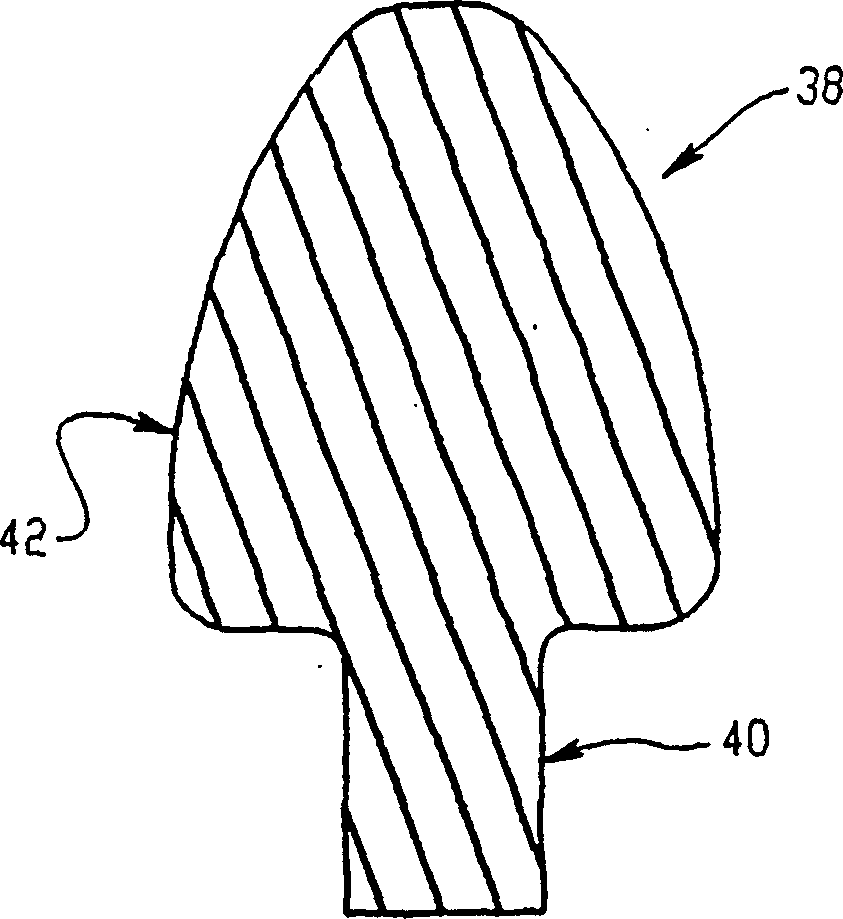

[0027] Each flange 16 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap