Low thermal expansion alloy excellent in low temperature stability and manufacturing method thereof

A low thermal expansion, manufacturing method technology, applied in the direction of manufacturing tools, additive manufacturing, metal processing equipment, etc., can solve the problems of unstably obtained, unobtained materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, examples of the present invention will be described.

[0076] Test materials were prepared by lamination molding alloys with the chemical composition and composition shown in Table 1 and by casting in pure copper molds.

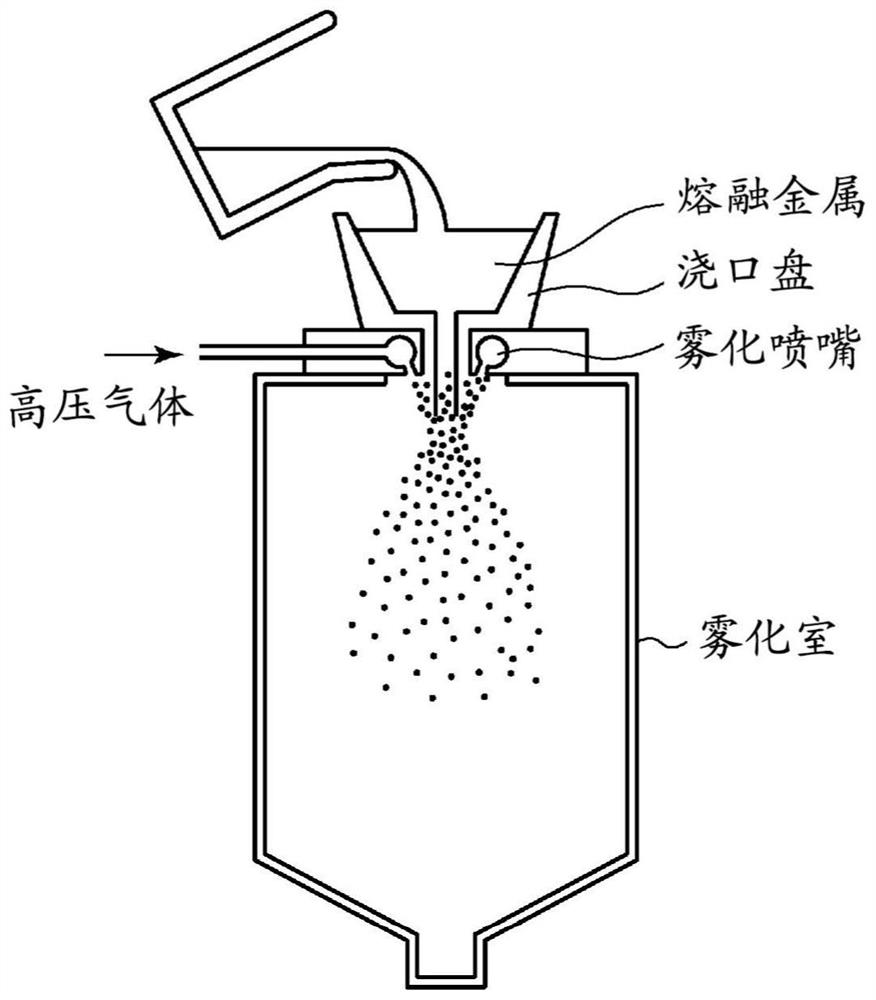

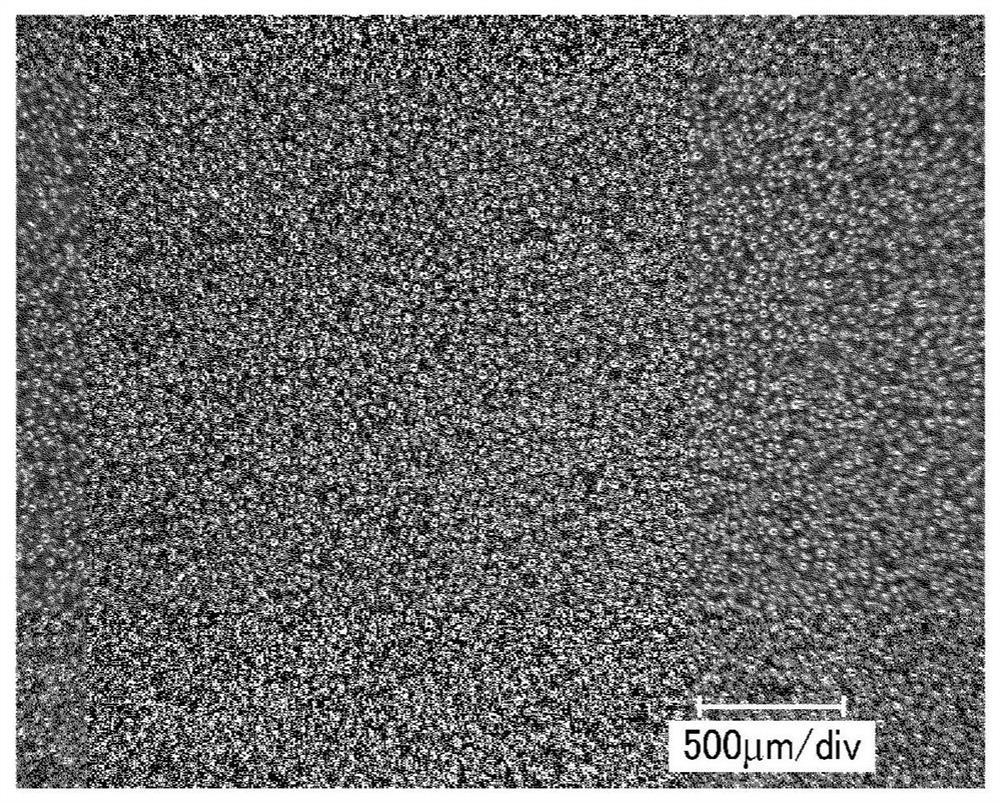

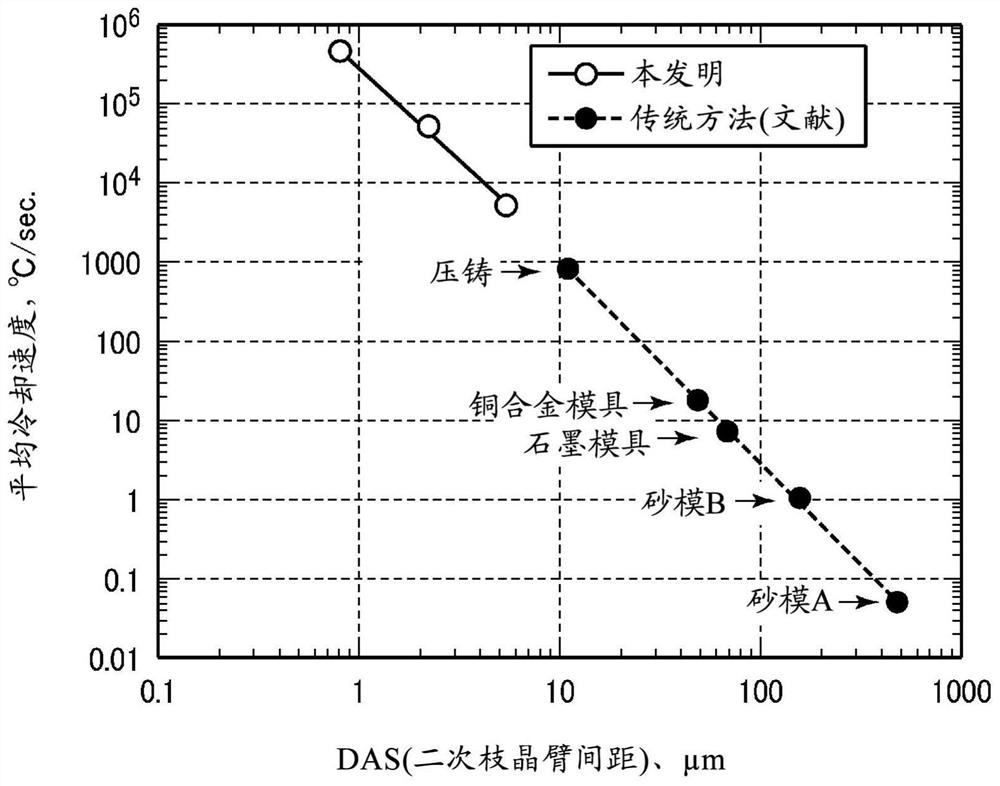

[0077] As for the test material of laminated molding, by melting an alloy with the chemical composition shown in Table 1 with a high-frequency induction furnace, use figure 1 In the atomization device shown, molten metal is dropped, and an inert gas (nitrogen gas in this example) is sprayed from a nozzle to rapidly solidify the droplets while splitting them to obtain a spherical powder. Thereafter, sieving was carried out to obtain figure 2 Modeling powder with a particle size of 10 to 45 μm shown. Using a laser-type laminated molding device, under the conditions of an output power of 300W, a laser moving speed of 1000mm / s, a laser scanning distance of 0.1mm, and a powder laminate thickness of 0.04mm, the laminated molding is performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com