a joint bearing

A technology of spherical plain bearings and bearing outer rings, applied in the field of spherical plain bearings, can solve problems such as inability to meet equipment maintenance requirements, poor accuracy, time-consuming and laborious, etc., achieve real-time detection, increase functions, and save extra space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

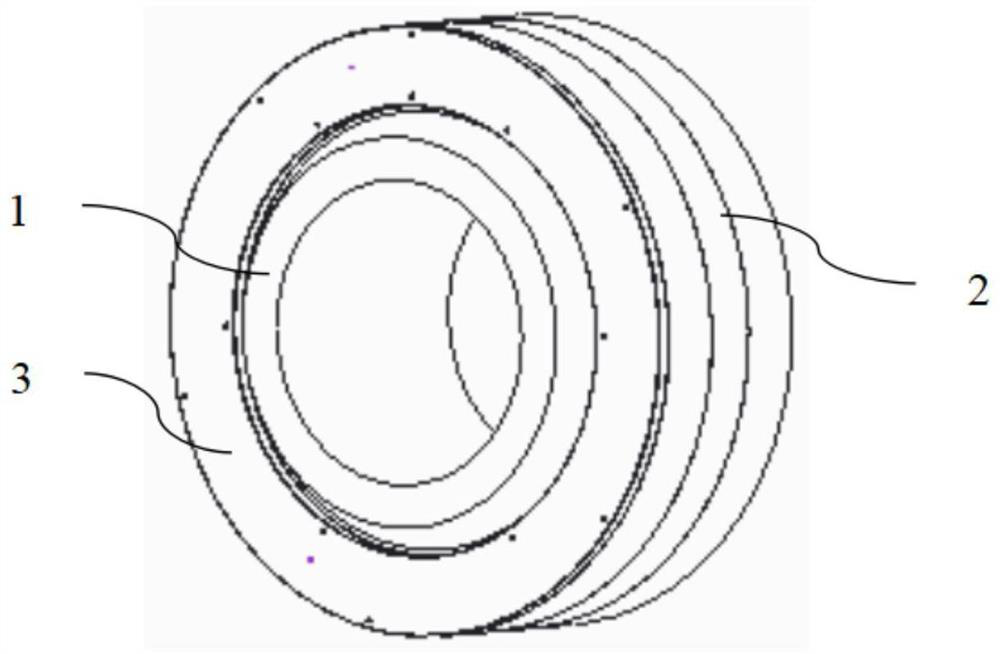

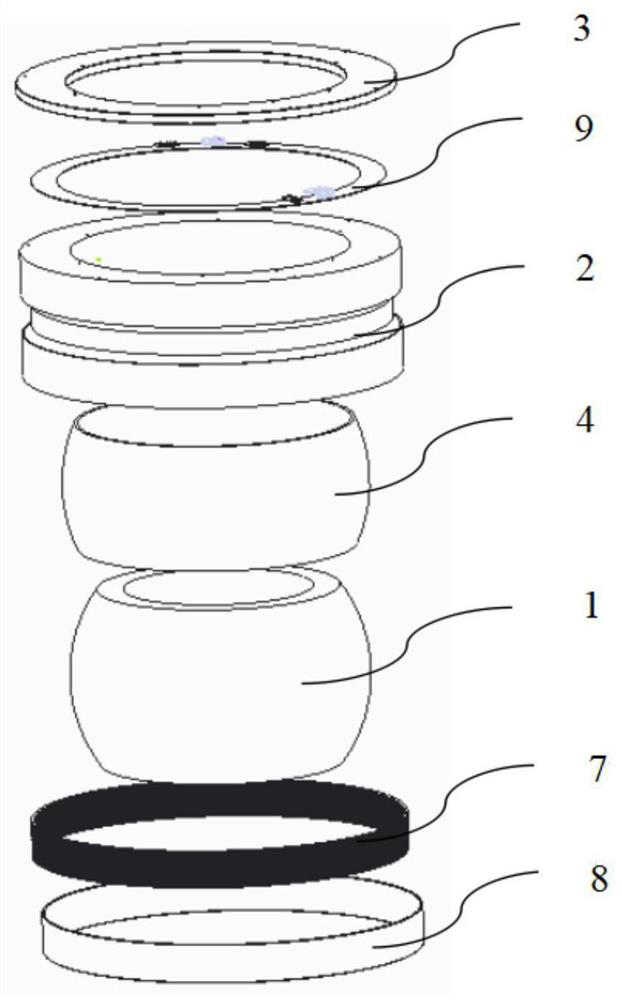

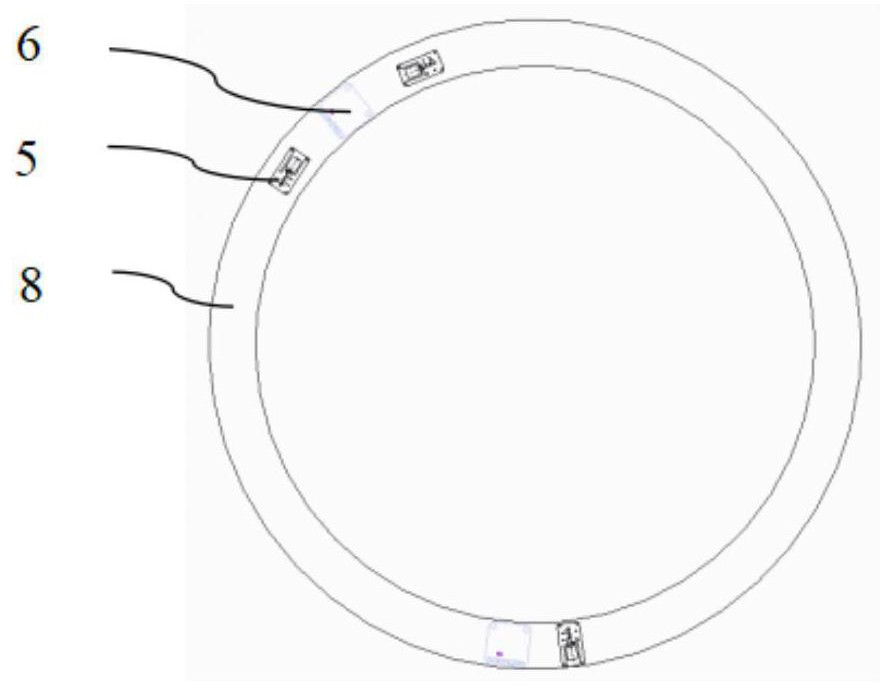

[0016] The joint bearing proposed by the present invention has a structure such as figure 1 and figure 2 As shown, it includes bearing inner ring 1, bearing outer ring 2, bearing end cover 3 and self-lubricating layer 4; also includes flexible circuit board 8, micro sensor integration system 5, wireless information transmission system 6 and wireless power supply system 7; The self-lubricating layer 4 is installed between the bearing inner ring 1 and the bearing outer ring 2, and the end surface of the bearing outer ring 2 is provided with countersunk holes for installing fasteners; the bearing outer ring 2 and the bearing end cover 3 Connected by fasteners; the flexible circuit board 9 is installed on the inner side of the bearing end cover 3, and the flexible circuit board 9 and the bearing end cover 3 are thermally fused into one; the micro sensor integrated system 5 and the wireless information transmission system 6 It is arranged on the flexible circuit board 9; the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com