Heat dissipation type silicone oil clutch

A silicone oil clutch, heat dissipation technology, applied in clutches, fluid clutches, machines/engines, etc., can solve problems such as the inability to meet the heat dissipation requirements of high torque clutches, reduce the reliability of silicone oil clutches, and reduce the efficiency of fan kinetic energy, and achieve savings. Production of raw materials, elimination of stomatal inspection costs, and small thermal shock effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] The heat-dissipating silicone oil clutch of the present invention is suitable for engine cooling systems of various mainstream platforms, especially cooling systems that require high torque output and high fan speed. Large torque output means that there will be more silicone oil inside the silicone oil clutch to provide torque through shearing force, and the heat will be more serious. If the heat dissipation is not timely, the internal parts of the silicone oil clutch will fail; the cooling capacity of the heat dissipation silicone oil clutch of the present invention Excellent, it can effectively avoid the high temperature of the silicone oil clutch, and greatly reduce the possibility of failure of the silicone oil clutch at high temperature.

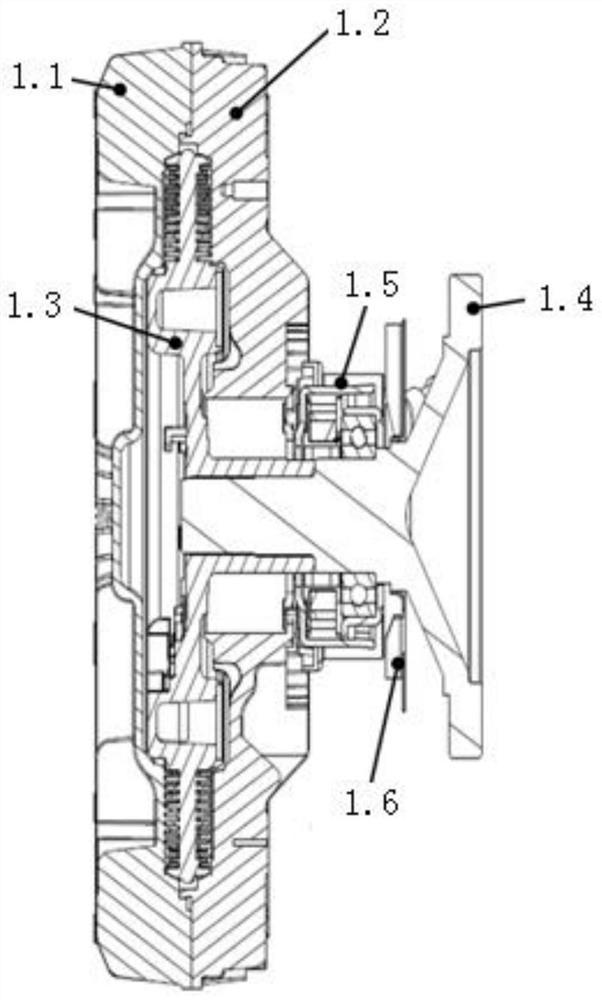

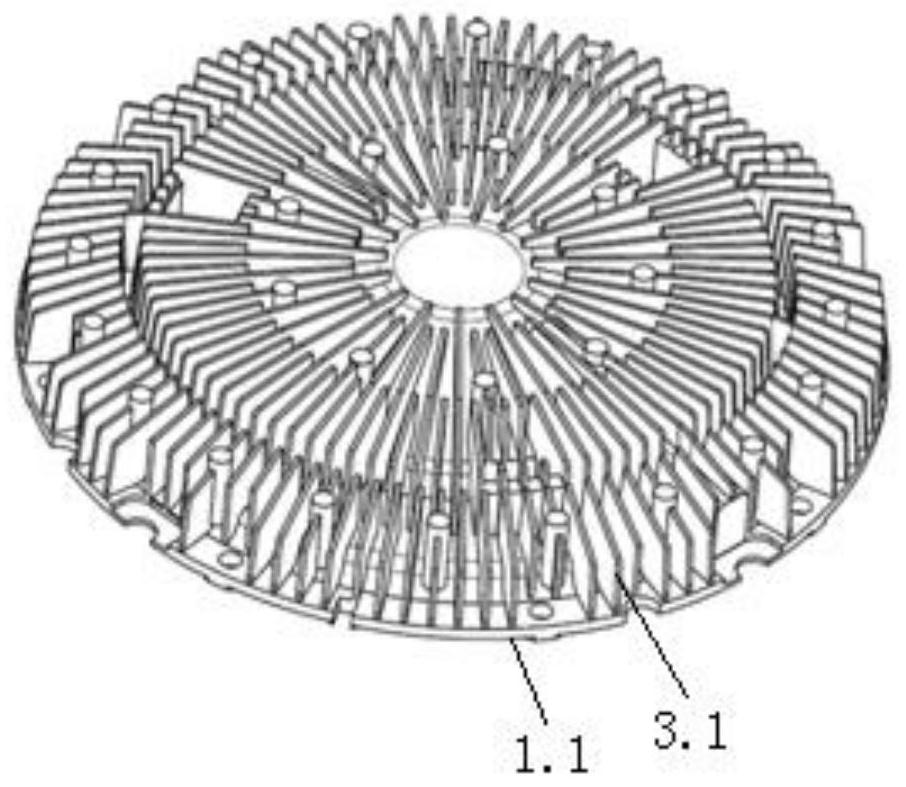

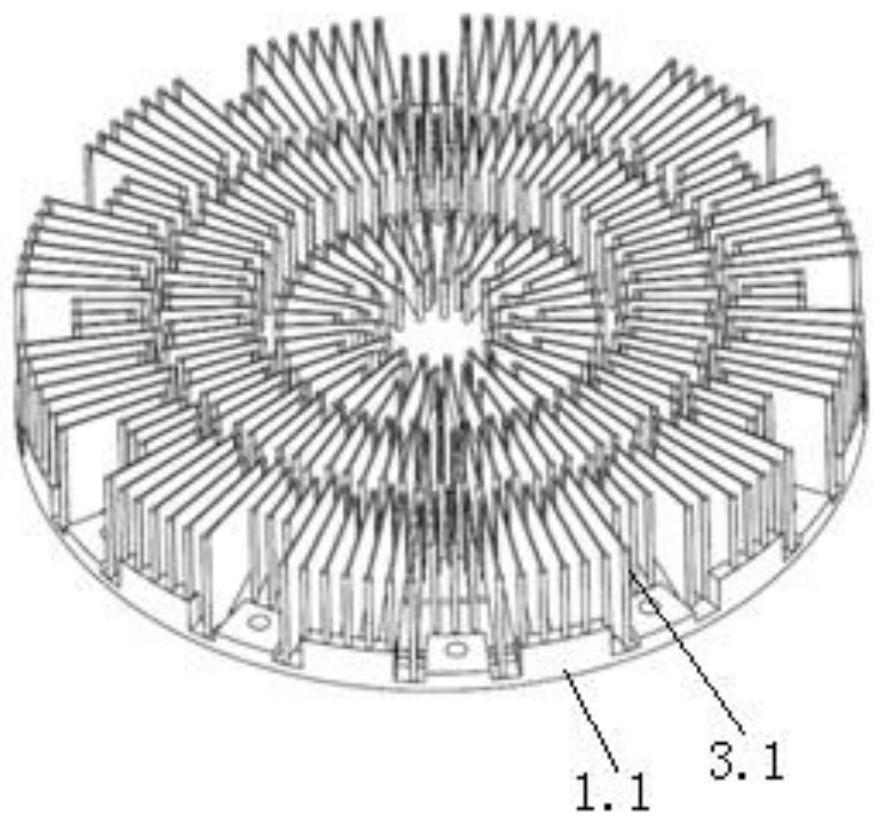

[0034] Such as figure 1 As shown, a heat dissipation silicone oil clutch of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com