Tactile sensor, slip sensor, working method thereof, and dual-integrated sensor

A technology of tactile sensors and working methods, applied in the field of sensors, can solve problems such as the inability to effectively perceive the direction and size of sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

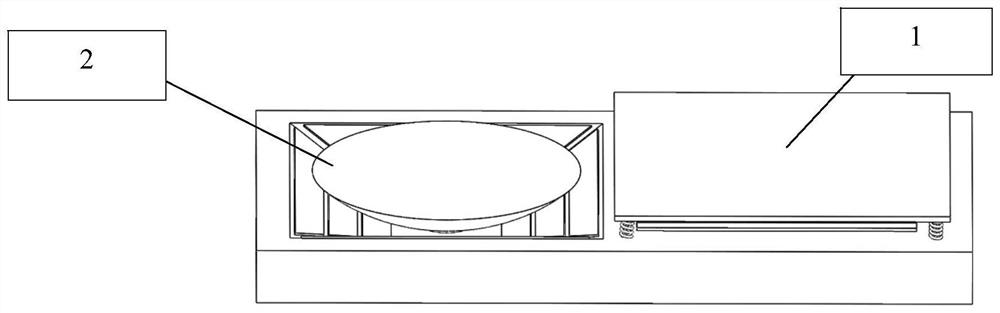

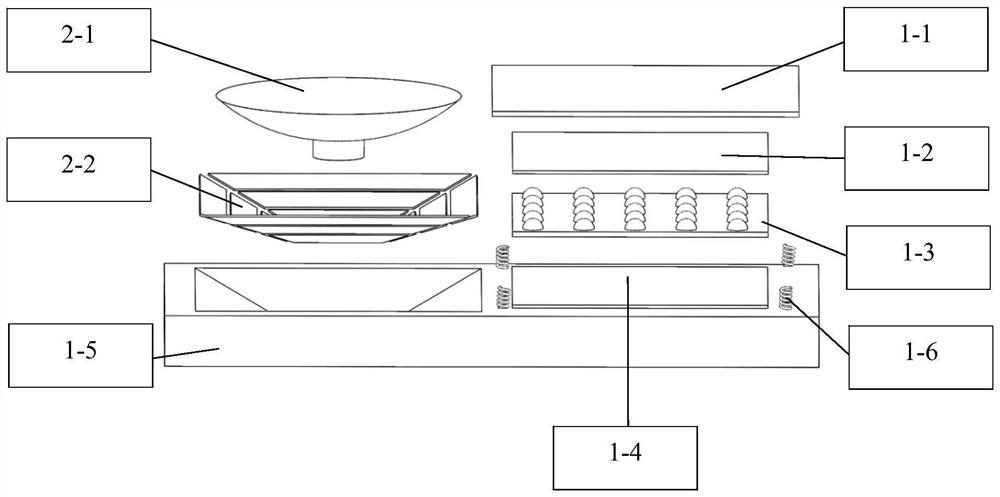

[0047] Such as Figure 1-2 Shown:

[0048] Tactile sensor 1 includes:

[0049] The first layer 1-1: polymethyl methacrylate board;

[0050] Second layer 1-2: copper layer, it has the effect of electrode and friction layer concurrently;

[0051] The third layer 1-3: polydimethylsiloxane friction layer;

[0052] The fourth layer 1-4: copper layer;

[0053] The fifth layer 1-5: polymethyl methacrylate board;

[0054] spring 1-6;

[0055] The lower surface of the first layer 1-1 is electroplated with the second layer 1-2;

[0056] The upper surface of the fifth layer 1-5 is electroplated with the fourth layer 1-4, and the upper surface of the fourth layer 1-4 is coated with the third layer 1-3;

[0057] The first layer and the fifth layer are connected together by more than 4 springs 1-6;

[0058] Under normal circumstances, the second layer 1-2: there is a layer of air gap before the third layer 1-3, which is convenient to restore deformation after contact;

[0059] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com