Calculation method for micro-crack thermally induced conductivity of hot dry rock mass

A technology of diversion capacity and calculation method, which is applied in calculation, computer-aided design, earthwork drilling and production, etc., and can solve problems such as ignoring the original mechanical opening, unable to calculate temperature drop change, and excessive deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

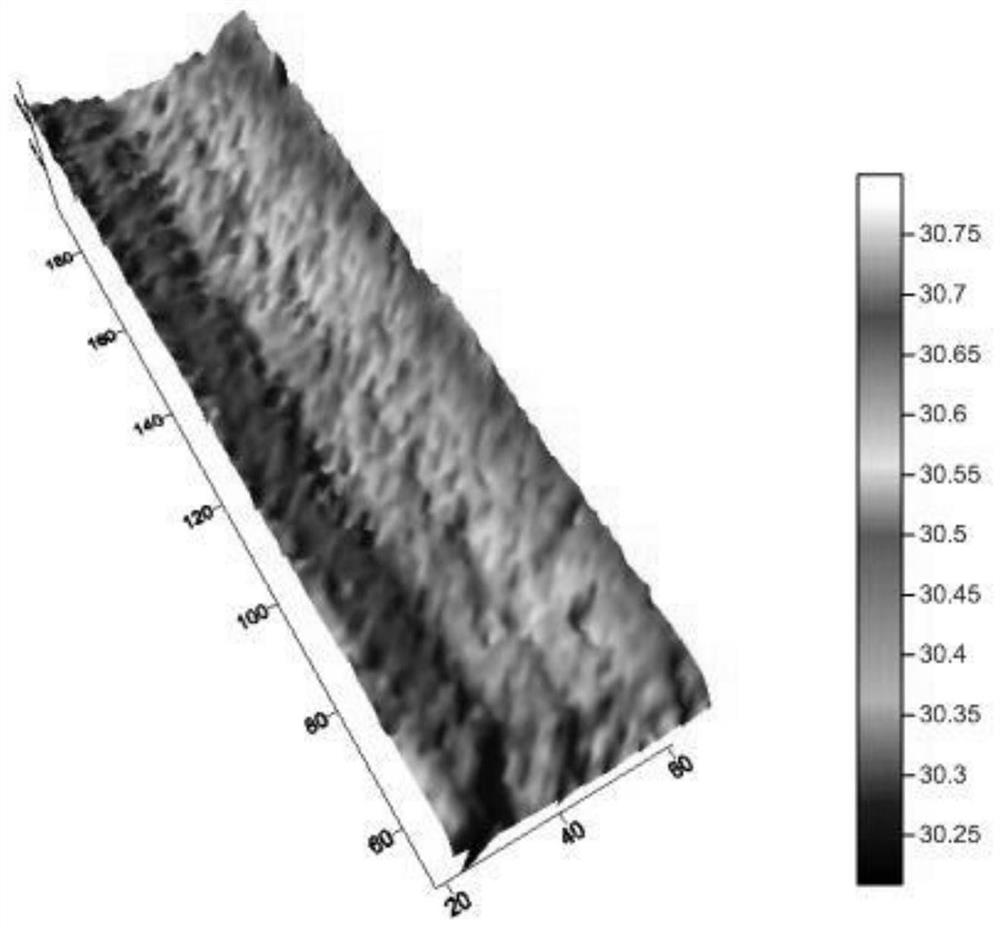

[0059] Step S1, collecting hot dry rock reservoir cores containing micro-cracks, splitting along the direction of micro-cracks, and cutting samples into rectangular slabs with a length of 150 cm and a width of 35 cm. Set the scanning accuracy of the rectangular rock slab to 0.1 mm in the length and width directions, and obtain the morphology data of the micro-cracks on the two-dimensional plane through laser scanning, such as figure 1 shown.

[0060] Step S2, calculating according to formula (1) and formula (2), the roughness coefficient of the micro-crack is 21.3.

[0061] Step S3, setting the maximum principal stress σ under the in-situ state where the micro-crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com