Chemical material dissolving device

A technology for dissolving devices and materials, applied in the directions of dissolution, chemical/physical processes, transportation and packaging, etc. It can solve the problems of small contact area and affect the dissolution efficiency of chemical materials, and achieve the effect of improving the dissolution rate and fast efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

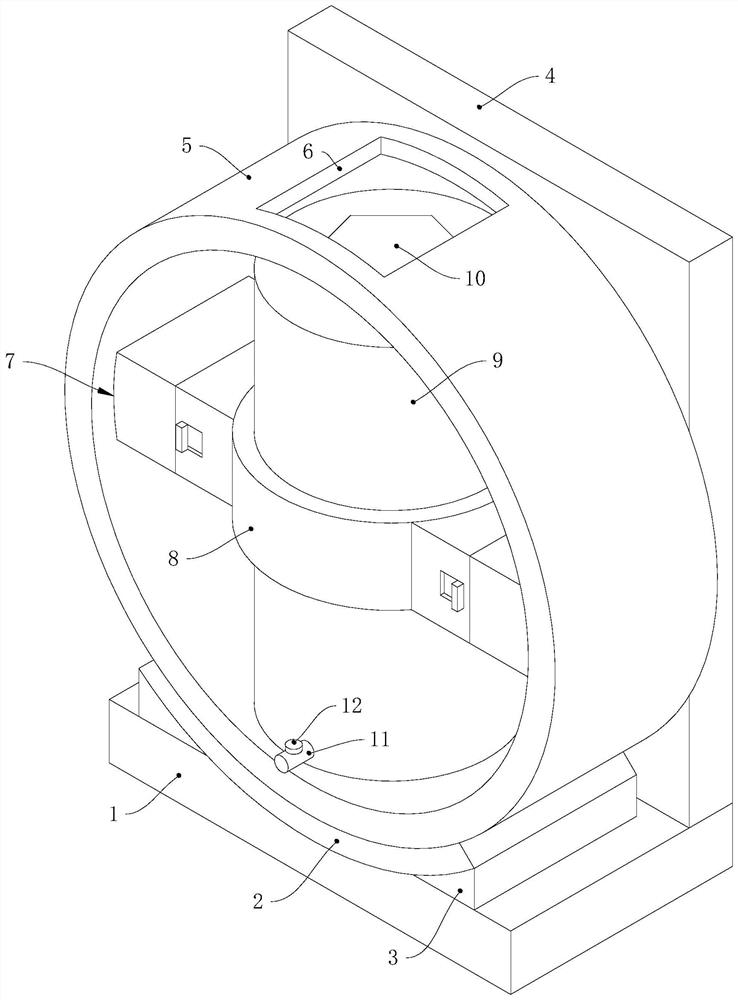

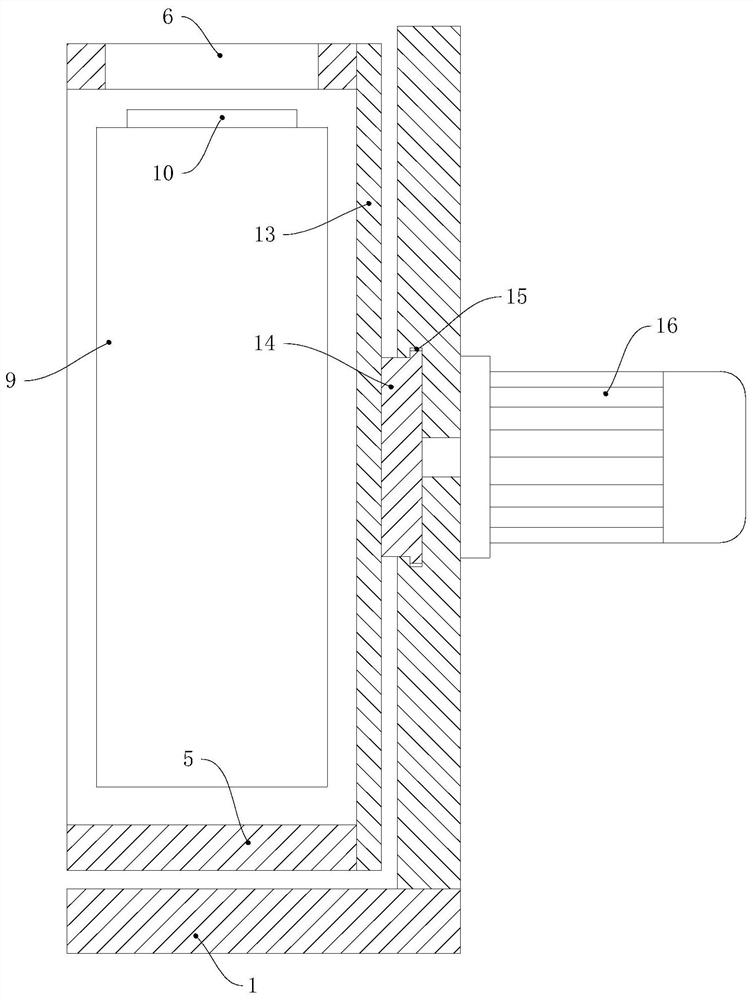

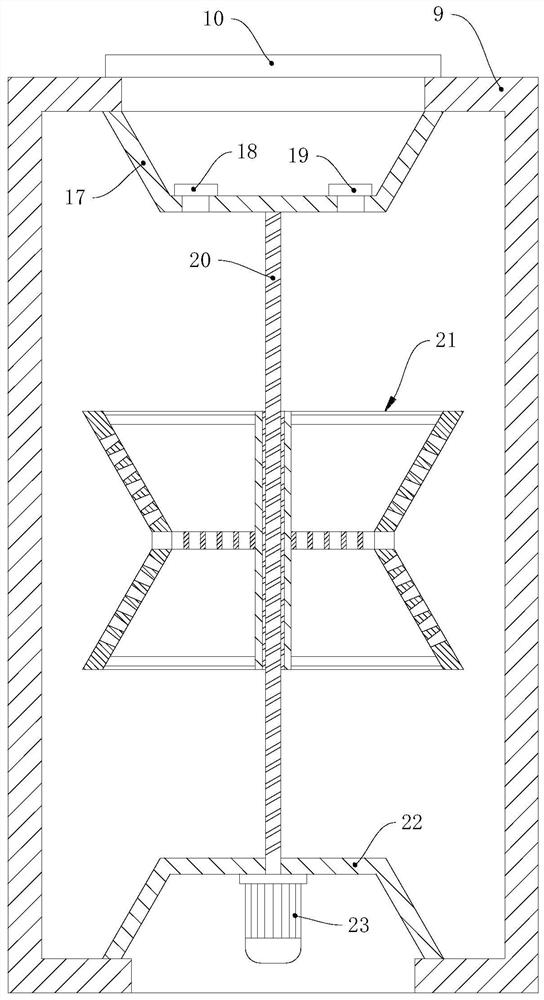

[0028] Example: such as Figure 1-6As shown, a dissolving device for chemical materials of the present invention comprises a base 1 and a dissolving tank 9 for dissolving chemical materials, the dissolving tank 9 is connected with a discharge pipe 11, and the discharge pipe 11 is provided with a control valve 12, The top of base 1 is provided with mounting plate 4, and the middle part of mounting plate 4 is fixedly installed with the first stepping motor 16, and one end of mounting plate 4 away from the first stepping motor 16 is provided with the output shaft of the first stepping motor 16 Connecting connecting plate 13, connecting plate 13 is provided with annular mounting ring 5 far away from the end of mounting plate 4, is provided with operating hole 6 on mounting ring 5, and dissolving tank 9 is located at the inside of mounting ring 5, and the two sides of dissolving tank 9 Both ends are provided with openings, and the openings are respectively provided with the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com