Recycled water stabilizing material prepared from waste earthwork and construction method thereof

A technology of earthwork and reclaimed water, applied in solid waste management, sustainable waste treatment, coagulation pavement for on-site paving, etc. The effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

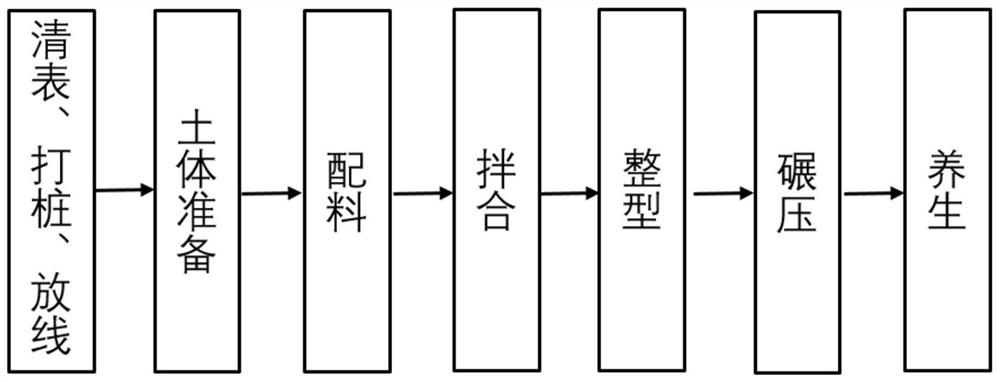

Method used

Image

Examples

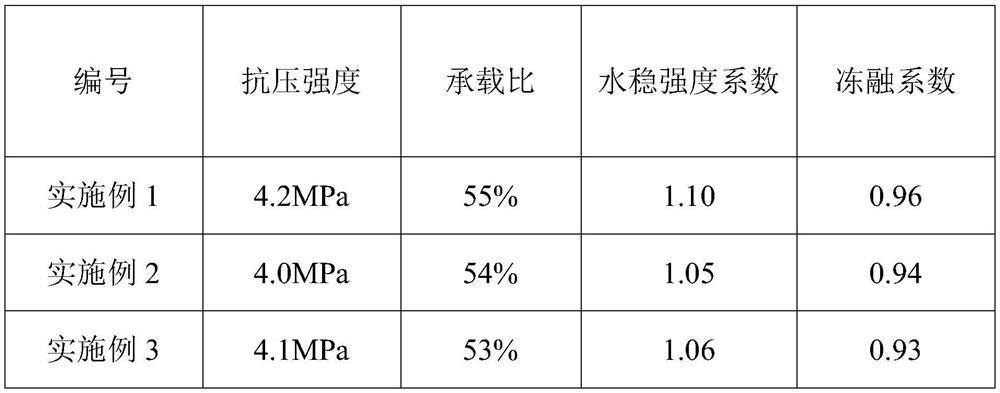

Embodiment 1

[0055] This example provides a recycled water stabilizer prepared by using waste earth and stone, including the following components by mass: 96 parts of waste earth and stone and 4 parts of the above-mentioned high-performance inorganic polymer cementitious material;

[0056] Wherein, the high-performance inorganic polymer cementitious material comprises the component of following mass parts: 110 parts of cement and 2 parts of composite admixtures;

[0057] Among them, the composite admixture includes the following components by mass: 30 parts of polycarboxylate superplasticizer, 3 parts of potassium dihydrogen phosphate, 3 parts of sodium lauryl sulfate, 7 parts of modified rice husk ash, 2 parts of viscosity modifier parts and 35 parts of water;

[0058] The viscosity regulator is composed of latex powder and cellulose-based thickener in a ratio of 2:1 in parts by mass;

[0059] Modified rice husk ash is prepared by the following methods:

[0060] Step (1): adding rice hu...

Embodiment 2

[0073] This example provides a regenerated water stabilizer prepared by using waste earthwork and its construction method. The only difference from Example 1 is that the regenerated water stabilizer includes the following components by mass: 93 parts of waste earthwork and high-performance inorganic polymer gelling 3 parts of materials; among them, the high-performance inorganic polymer cementitious material includes the following components by mass: 100 parts of cement and 1 part of composite admixture; the rest of the steps and parameters are the same.

Embodiment 3

[0075] This example provides a regenerated water stabilizer prepared by using waste earthwork and its construction method. The only difference from Example 1 is that the regenerated water stabilizer includes the following components by mass: 93 parts of waste earthwork and high-performance inorganic polymer gelling 3 parts of materials; among them, the high-performance inorganic polymer cementitious material includes the following components by mass: 120 parts of cement and 4 parts of composite admixture; the rest of the steps and parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com