Round granular potash fertilizer with instant characteristic and preparation method thereof

A technology of round granule and potash fertilizer, which is applied in the field of instant round granule potash fertilizer and its preparation, which can solve the problems of heavy dust, poor fertilization, slow fertilizer dissolution, slow crop absorption, etc., and achieve the effect of convenient large-scale fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) put bentonite and potassium sulfate into two feed bins respectively and put in the material by controlling the metering scale, and put the material into the ball mill with bentonite and potassium sulfate in a ratio of 1.5:8.5 for mixing and grinding for 30 minutes;

[0026] (2) The mixed material is conveyed to the granulation drum through the belt, and the water is atomized and sprayed to the surface of the fertilizer through the atomizing nozzle to form potassium sulfate into particles;

[0027] (3) Send the granulated potassium sulfate into the drying drum for drying, and then sieve and pack the fertilizer after drying.

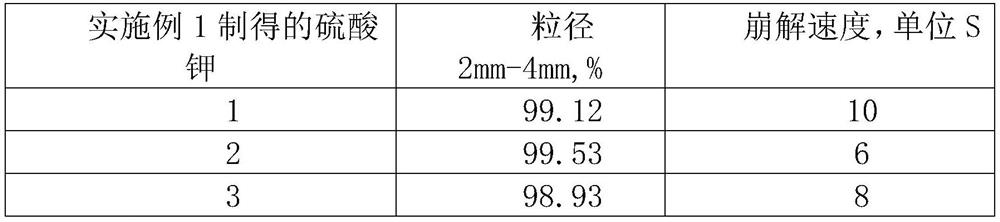

[0028]

Embodiment 2

[0030] (1) Put the modified soil and potassium chloride into two silos respectively, and put the materials into the ball mill with the ratio of 0.5:9.5 to the modified soil and potassium chloride for mixing and grinding. 30min;

[0031] (2) The mixed material is conveyed to the granulation drum through the belt, and the water is atomized and sprayed to the surface of the fertilizer through the atomizing nozzle to form potassium chloride particles;

[0032] (3) Send the granulated potassium chloride into the drying drum for drying, and then sieve and pack the fertilizer after drying.

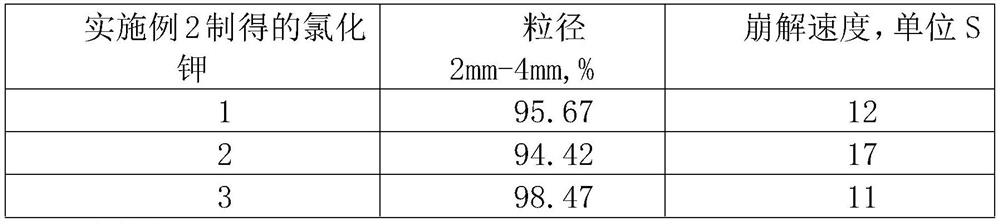

[0033]

Embodiment 3

[0035] (1) Put the attapulgite and potassium sulfate into two silos respectively to put in the materials by controlling the metering scale, and put the materials into the ball mill with the attapulgite and potassium sulfate in a ratio of 1:9 for mixing and grinding for 10 minutes;

[0036] (2) The mixed material is conveyed in the granulation drum through the belt, and the mass concentration is 0.5% PVA aqueous solution, which is atomized and sprayed to the fertilizer surface by the atomizing nozzle to make potassium sulfate form particles;

[0037] (3) Send the granulated potassium sulfate into the drying drum for drying, and then sieve and pack the fertilizer after drying.

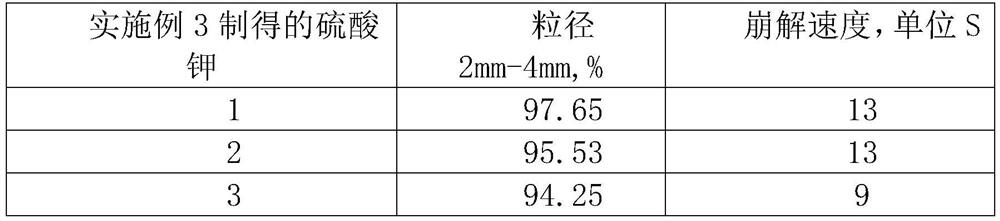

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com