Construction method of cast-in-situ bored pile under special geological conditions

A technology of bored piles and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as the reduction of foundation pile bearing capacity, and achieve the effects of saving engineering costs, low overall costs, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

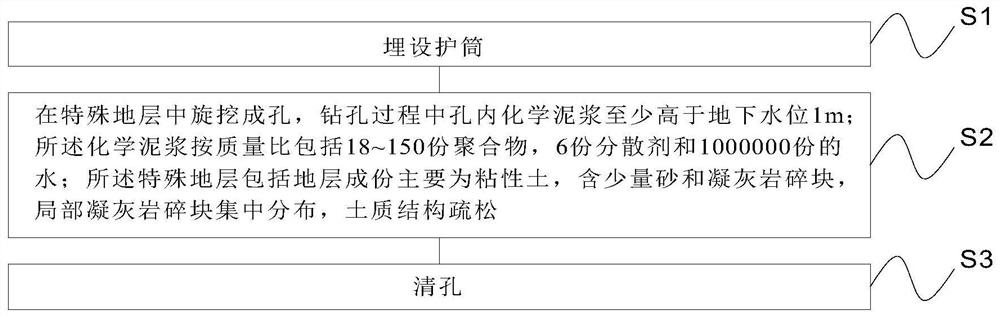

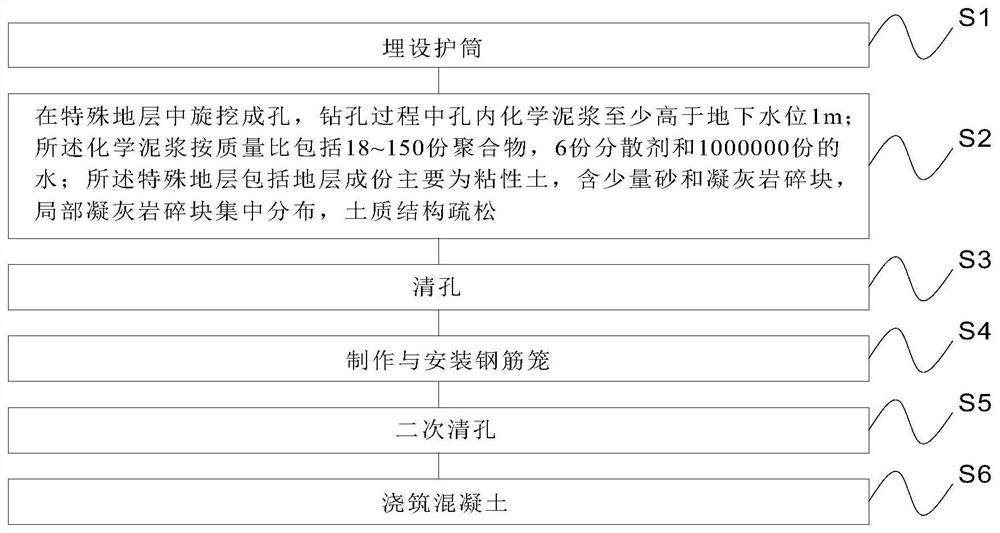

Method used

Image

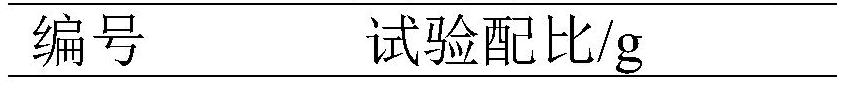

Examples

Embodiment

[0039] Embodiments of the present invention rely on a pile foundation project in Hainan as an example, the technical solutions of the present invention will be described in detail.

[0040] Exploration of engineering geology, according to field drilling, in situ test and indoor geotechnical test results, according to the era of geotechnical, the cause, rock and physical mechanics properties, the formation of the plant exploration, in this example The special formation referred to is divided into 4 layers, and is now described below:

[0041] One-beam filling (Q 4 ml : Gray brown ~ brown yellow, uneven soil, the ingredients are mainly viscous soil, including small amounts of sand and coagulatory blocks, local jasteolite, local coagulatory block concentrated distribution, hard impurities ≤ 25%. According to the survey, the layer belongs to the new backfilling soil, and then the uniformity is poor. This layer is generally distributed within the venue, with a layer thickness of 0.9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com