Wastewater treatment system and process

A wastewater treatment system and process technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the complicated sources of sewage, differences in operation methods and processes, domestic water and living environment hazards, etc. problem, to achieve the effect of efficient purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

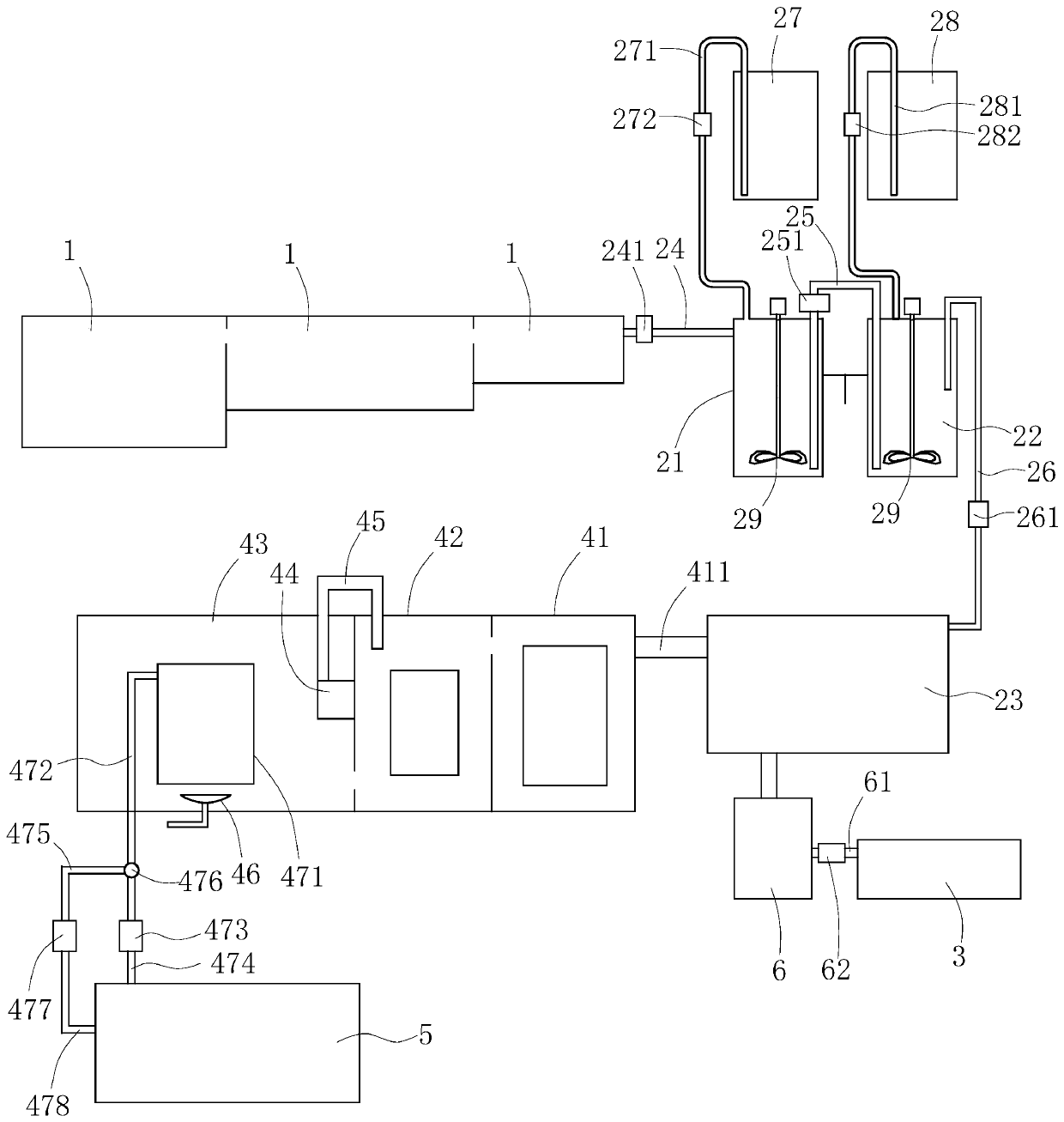

[0052] refer to figure 1 , is a wastewater treatment system disclosed in the present invention, comprising a regulating pool 1, physical and chemical integrated treatment equipment, a filter press 3, biochemical membrane treatment integrated treatment equipment and a clean water pool 5. The regulating pool 1 is mainly used for temporarily storing and settling the cleaning wastewater. There are at least two regulating pools 1. In this embodiment, there are three regulating pools 1. The upper parts of the regulating pools 1 are connected in turn, and the depth of each regulating pool 1 is along the water flow. The direction decreases gradually, so that the sediments with different particle sizes can be settled into different adjustment tanks 1 by using the shallow pool theory.

[0053] refer to figure 1 The atomization integrated treatment equipment includes a demulsification coagulation reaction tank 21, a flocculation tank 22 and an air flotation machine 23, and a liquid inle...

Embodiment 2

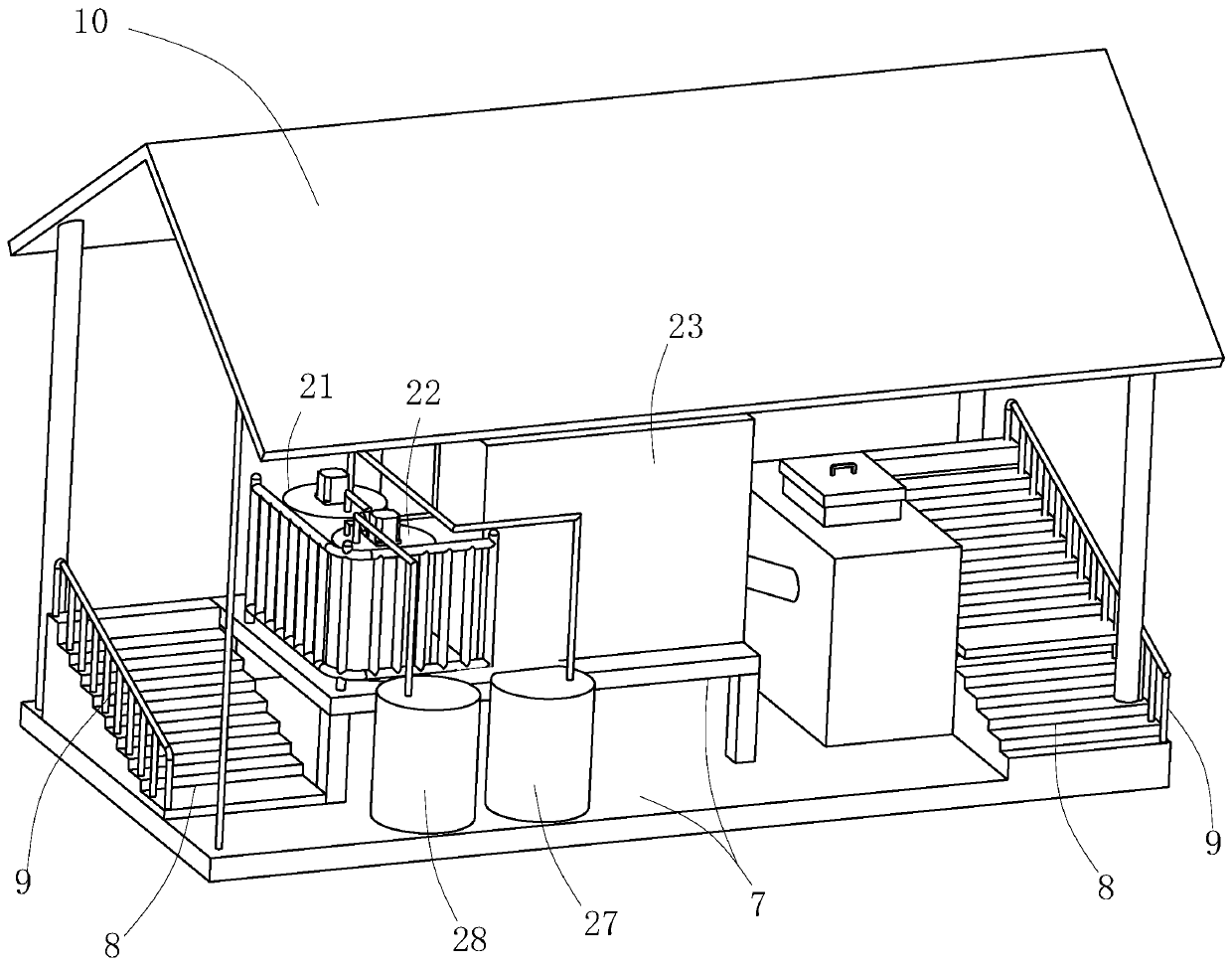

[0061] refer to figure 2 The difference between this embodiment and Embodiment 1 is that the waste water treatment system also includes a support platform 7, a demulsification coagulation reaction tank 21, a flocculation tank 22, an air flotation machine 23, an A reagent storage tank, a B reagent storage tank and The biochemical film treatment integrated treatment equipment is all arranged on the support platform 7, and the water outlet of the air flotation machine 23 is higher than the biochemical film treatment integrated treatment equipment; a pedal 8 is installed on the support platform 7 side, around the support platform 7 and all Both sides of the pedal 8 are provided with guardrails 9. On the support platform 7, a rain-proof shed 10 is also installed to prevent the medicament from insolation, short-circuit and metal aging of the electrical components due to exposure to rain.

Embodiment 3

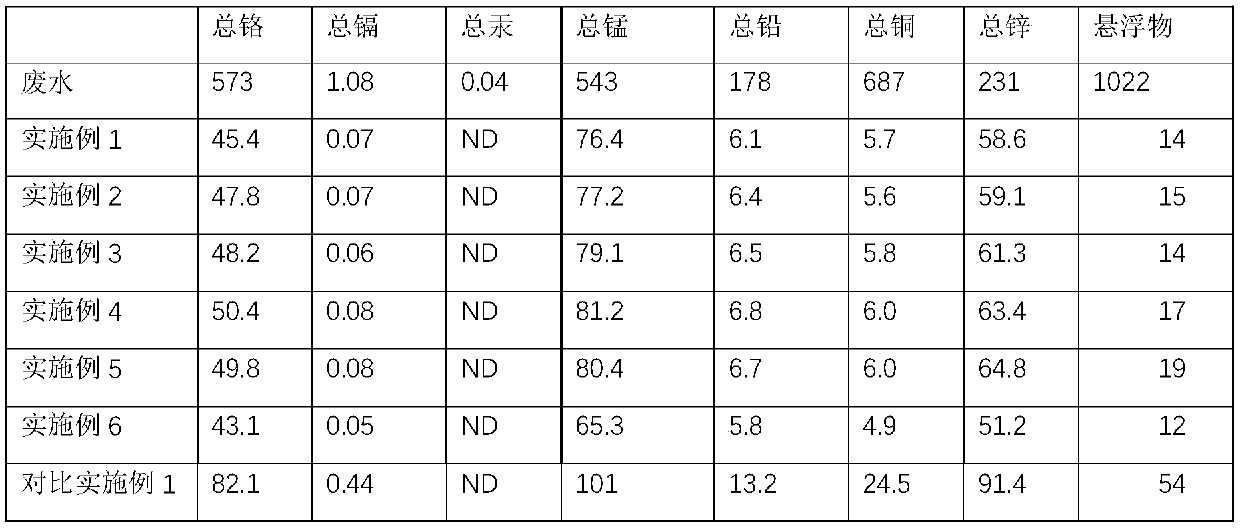

[0063] A wastewater treatment process, using the wastewater treatment system disclosed in Embodiment 1 to perform the following process: after the cleaning wastewater is generated, it is first discharged into the regulating tank 1 for preliminary precipitation, and then pumped into the demulsification coagulation reaction tank 21 through the liquid inlet pump 241, Add reagent A to the demulsification coagulation reaction tank 21 and make the stirring mechanism 29 stir at a speed of 50-70 rpm for 7-10 minutes. To break the emulsification, change the surface potential of dispersed solid suspensions, and destroy the electrical balance of metal ions, so that the oil stains in the wastewater are cleared, the solid suspensions are gradually gathered, and the Coulomb repulsion between metal ions is reduced, making these Oil stains, suspended solids and metal ions are mixed together to form a large number of aggregates. In this embodiment, reagent A includes: 75 parts by weight of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com