Purification and recovery system for dichloromethane waste gas

A methylene chloride and recovery system technology, applied in gas treatment, organic chemistry, chemical instruments and methods, etc., can solve problems such as harsh adsorption conditions and adsorption efficiency problems, and achieve economical purification treatment, stable operation, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

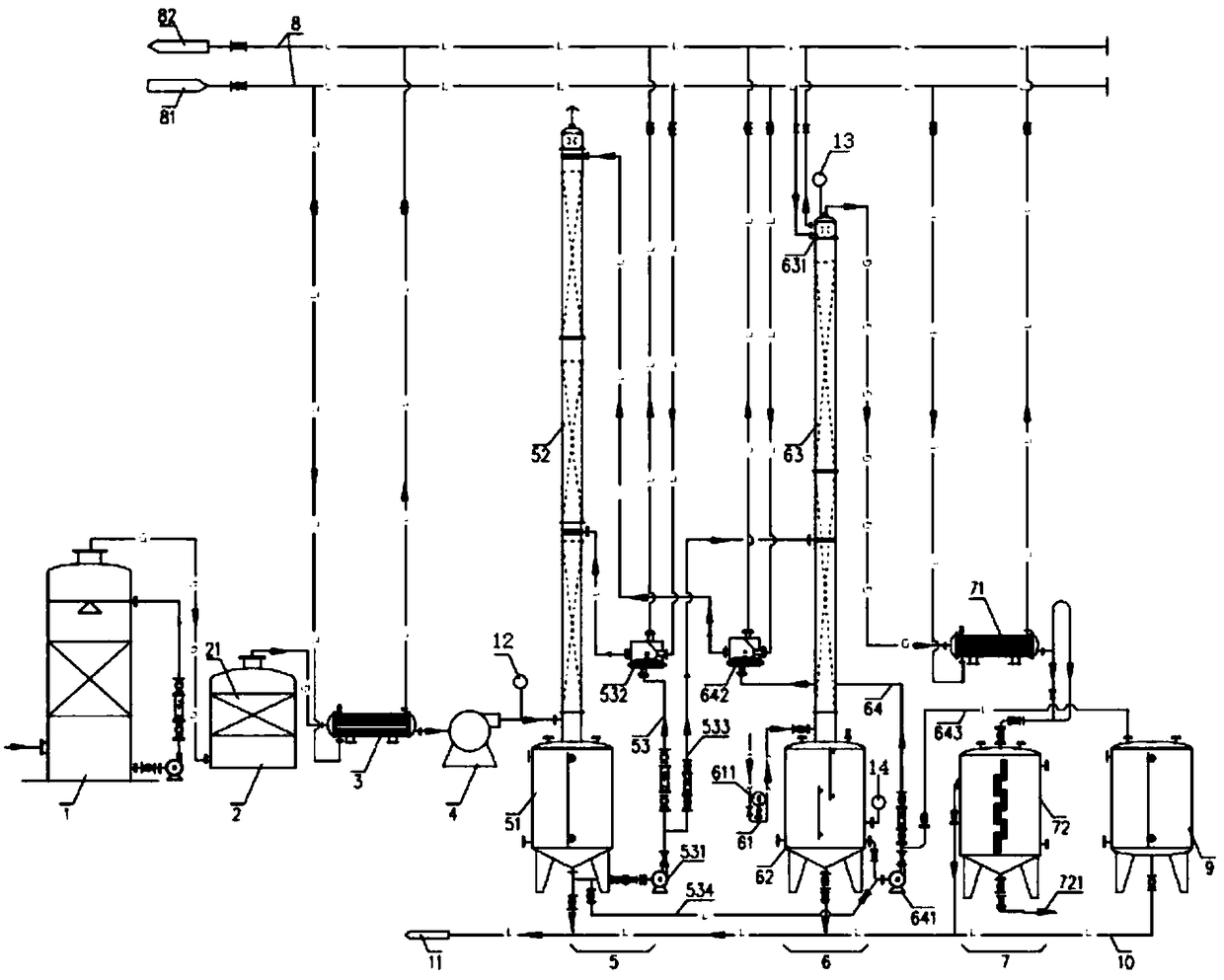

[0035] Such as figure 1 As shown, the present invention relates to a purification and recovery system of dichloromethane waste gas, the system includes a water spray tower 1 dedicated to removing soluble organic matter in the waste gas connected in sequence, and a demister tower 2 dedicated to removing water mist in the waste gas , Exclusive first tubular condenser for cooling and dehumidifying exhaust gas 3, Exclusive induced draft fan for pulling exhaust gas 4, Exclusive white oil absorption system for removing dichloromethane in exhaust gas 5, Exclusive absorption liquid for dichloromethane saturation A white oil desorption system 6 for desorption, a dichloromethane recovery system 7 dedicated to condensing and recovering high-concentration dichloromethane waste gas after desorption, and a waste water storage tank 9 connected to the white oil desorption system 6 exclusively for collecting waste water, A refrigerated brine circulation system exclusively connected to the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com