Modified composite flocculant for improving settling property of paper-making wastewater

A composite flocculant and settling performance technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, secondary pollution, poor flocculation effect, etc. Achieve the effect of promoting sedimentation, compaction of sedimentation, and optimization of electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

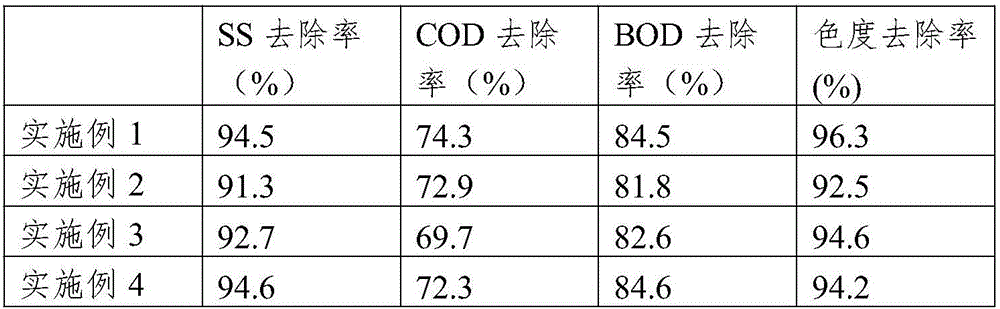

Examples

Embodiment 1

[0025] A modified composite flocculant for improving the settling performance of papermaking wastewater, consisting of the following mass fractions of raw materials:

[0026] Polyaluminum sulfate: 46wt%;

[0027] Bacillus subtilis liquid: 12wt%;

[0028] Bacteroides succinate producing liquid: 12wt%;

[0029] Alkyl polyglycosides: 2.5wt%;

[0030] Anionic polyacrylamide: 0.5wt%;

[0031] Bottom mud: 23wt%;

[0032] EDTA: 4 wt%.

Embodiment 2

[0034] A modified composite flocculant for improving the settling performance of papermaking wastewater, consisting of the following mass fractions of raw materials:

[0035] Alum: 30wt%;

[0036] Rhodococcus bacterium liquid: 12wt%;

[0037] White rot fungus liquid: 13wt%;

[0038] Alkyl polyglycosides: 4%;

[0039] Anionic polyacrylamide: 1wt%;

[0040] Activated silica: 35wt%;

[0041] EDTA: 5 wt%.

Embodiment 3

[0043] A modified composite flocculant for improving the settling performance of papermaking wastewater, consisting of the following mass fractions of raw materials:

[0044] Polyaluminum sulfate: 52wt%;

[0045] Bacillus subtilis liquid: 9wt%;

[0046] Rhodococcus erythropolis liquid: 5wt%;

[0047] Bacteroides succinate producing liquid: 4wt%;

[0048] Alkyl polyglycosides: 0.9wt%;

[0049] Anionic polyacrylamide: 4.1wt%;

[0050] Bottom mud: 20wt%;

[0051] EDTA: 5 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com