Numerical control machine tool noise reduction protective door

A technology of CNC machine tools and protective doors, which is applied in the field of CNC machine tools, can solve the problems of inconvenient use and large space occupation of CNC machine tools, and achieve the effects of reducing noise emission, enhancing cleaning, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

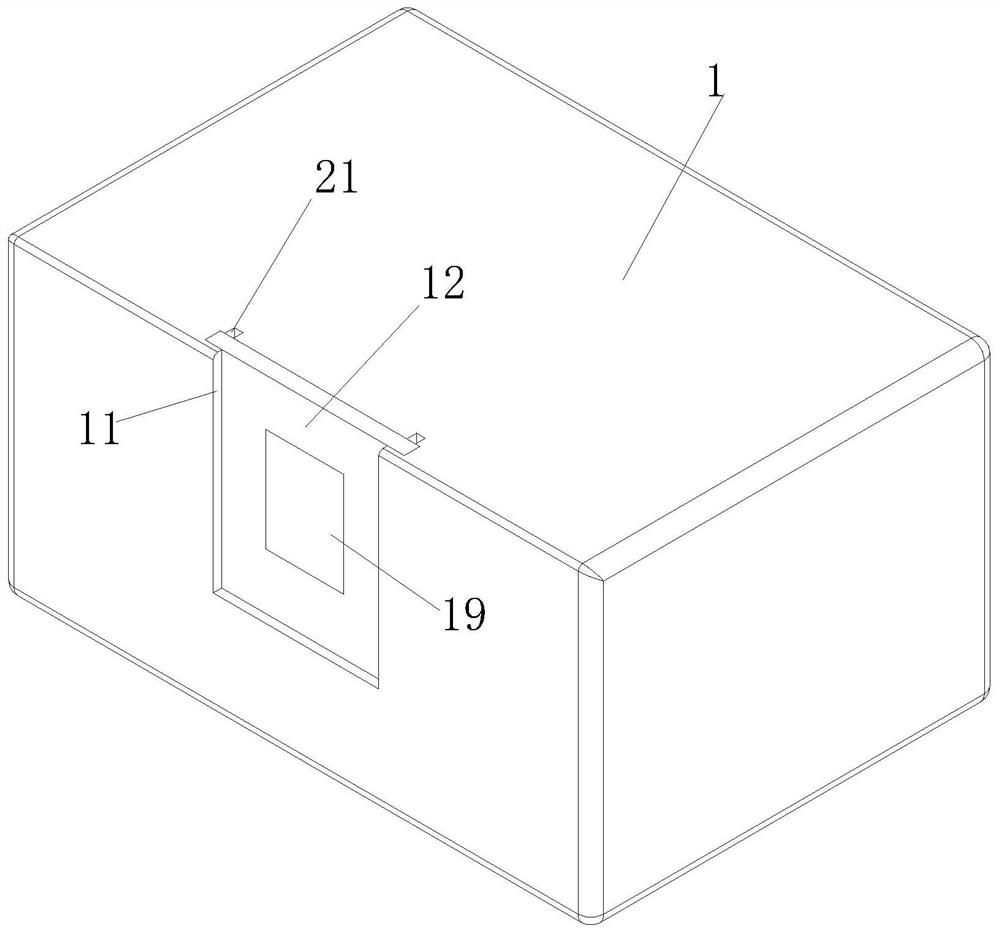

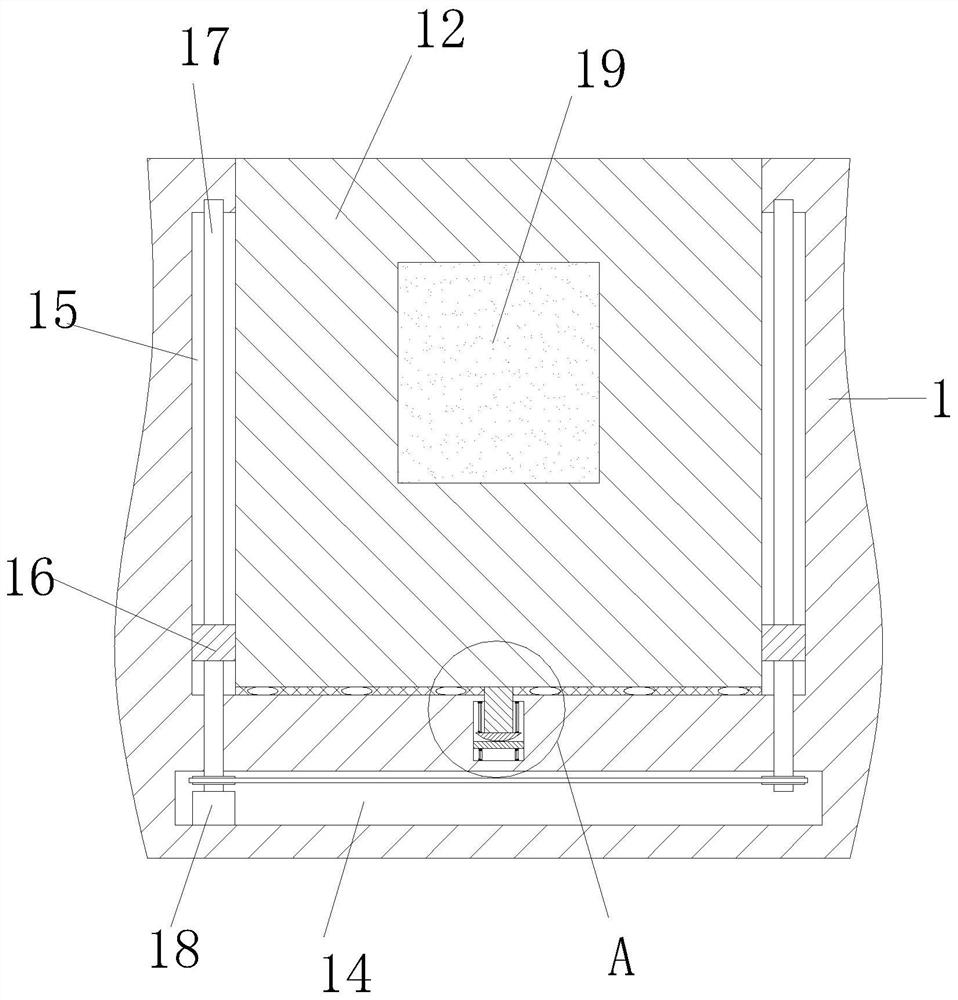

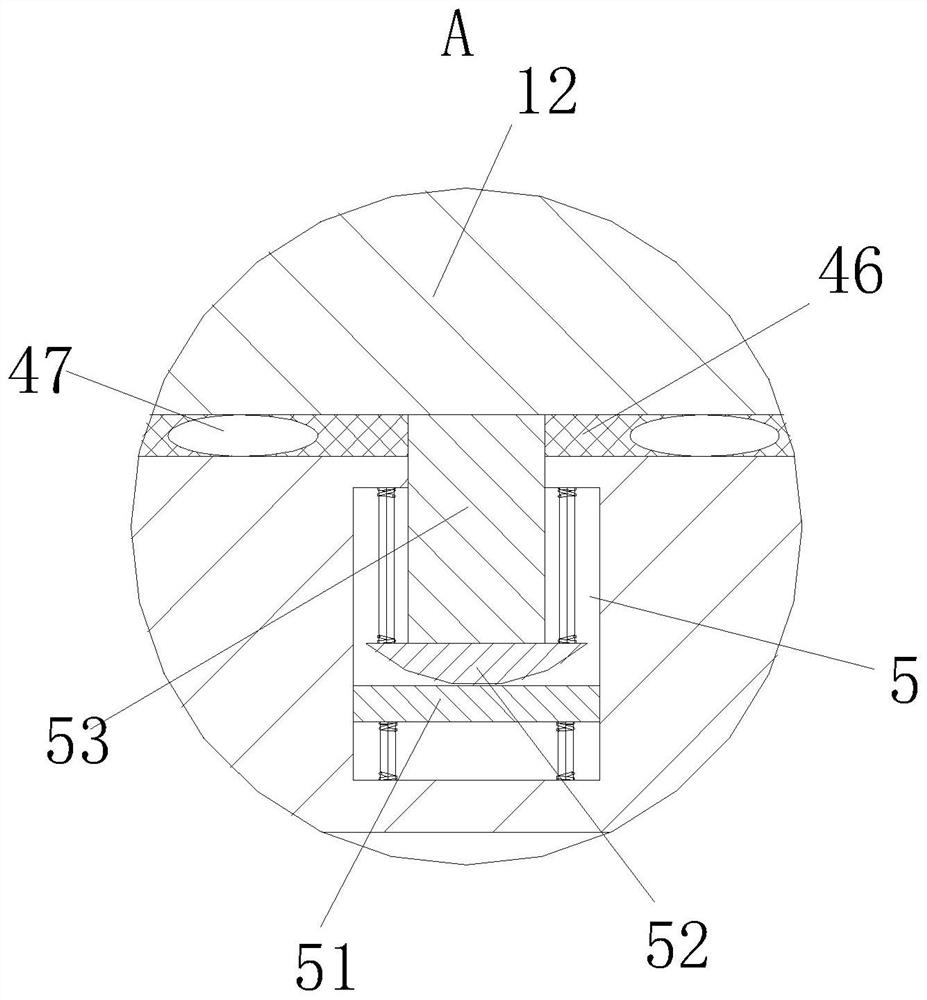

[0033] Such as Figure 1 to Figure 8 As shown, a kind of numerical control machine tool noise reduction protection door described in the present invention comprises a bed 1; the side wall of the bed 1 is provided with a door slot 11, and the side wall of the door slot 11 is provided with a surrounding slot 13; A protective door 12 is slidably connected to the surrounding groove 13; an observation window 19 is provided on the protective door 12, and double-layer glass is fixed in the observation window 19; a first cavity 14 is opened in the bottom of the surrounding groove 13 , and the groove bottom on both sides of the surrounding groove 13 is provided with a first groove 15; the top side wall of the first groove 15 is rotatably connected with a lead screw 17, and the bottom end of the lead screw 17 extends into the first cavity 14 , and the lead screw 17 stretches into the bar of the first cavity 14 and is fixedly connected with a sprocket; between the sprockets, it is driven...

Embodiment 2

[0043] see Figure 9 As shown in Comparative Example 1, as another embodiment of the present invention, a collection box 41 is affixed to the bottom end of the arc-shaped plate 4; during operation, a collection box 41 is affixed to the bottom end of the arc-shaped plate 4, The impurities thrown off from the cleaning wheel 2 and the impurities cleaned by the cleaning brush 45 will enter the collection chamber through the arc plate 4 .

[0044] Working principle: When it is necessary to open the CNC machine tool to place the product, start the motor 18, the motor 18 rotates through the sprocket and at the same time drives the screw 17 to rotate forward, and the forward rotation of the screw 17 will drive the moving block 16 to move upward in the first groove 15 , the moving block 16 moves to drive the protective door 12 upwards, and the protective door 12 is opened upwards. After the product is put into the bed 1, the motor 18 is turned to drive the lead screw 17 to reverse, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com