Riding law mower

A lawn mower, sitting technology, used in lawn mowers, harvesters, cutters, etc., can solve problems such as burning dry cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

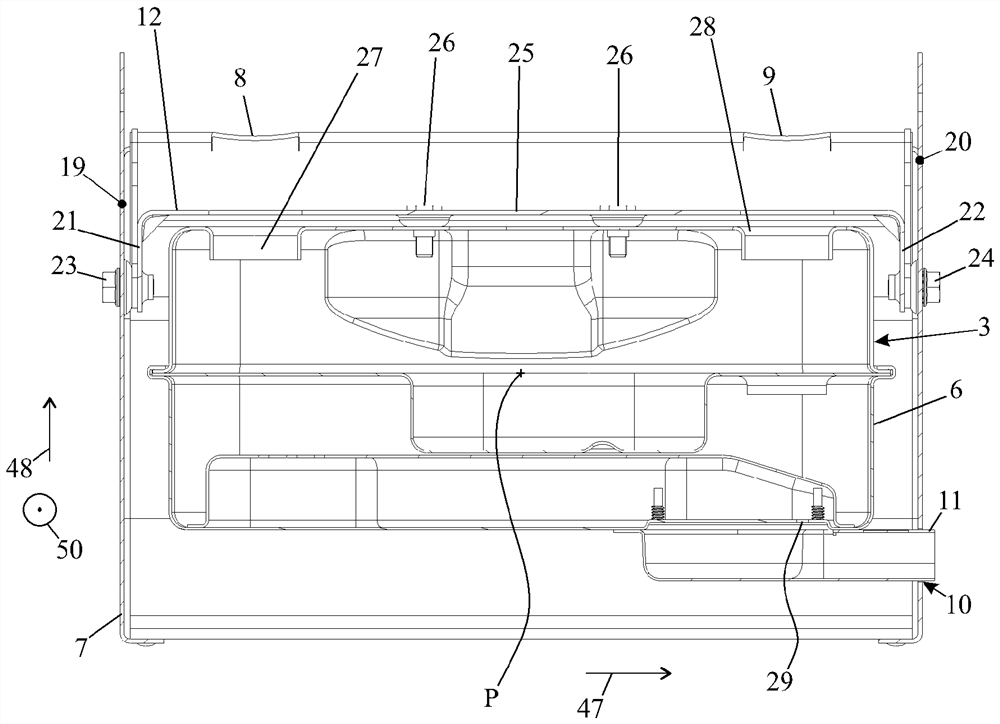

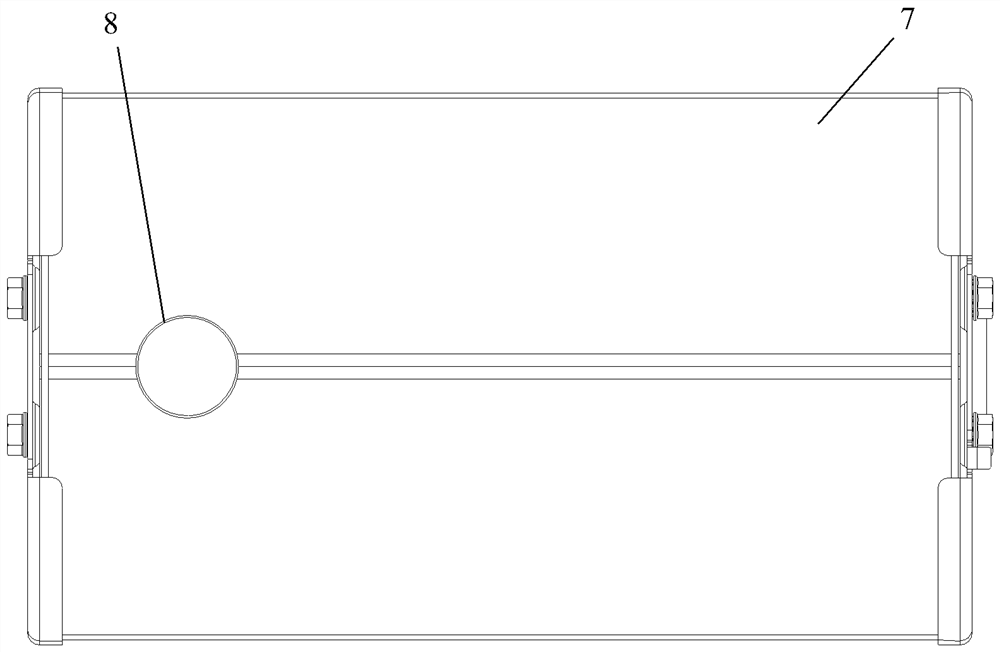

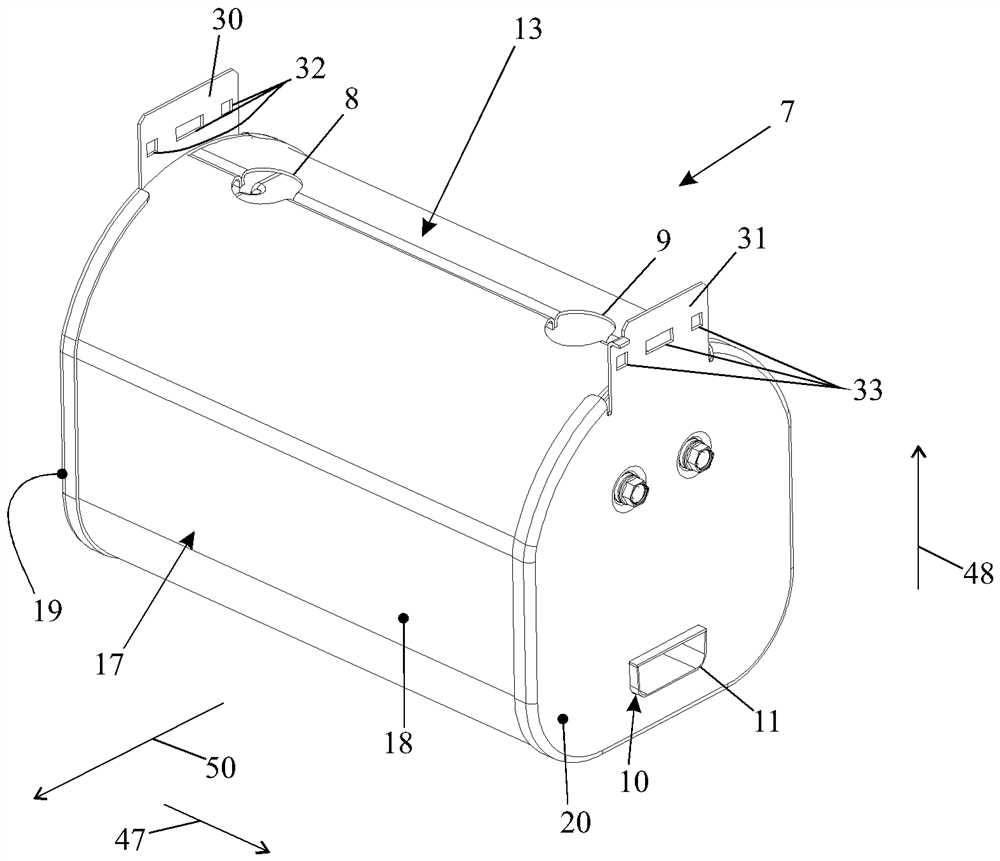

[0029] figure 1 A sit-down lawnmower 1 is shown. The sitting lawn mower 1 includes front wheels 41 . The front wheels 41 can be steered by means of a steering wheel 42 . When the sit-on lawn mower 1 is traveling straight, the sit-on lawn mower 1 travels in the direction of travel 50 . The direction of travel 50 extends in the direction of the longitudinal center axis 46 of the sit-on lawn mower 1 . When the sit-on lawnmower 1 is traveling straight ahead, the front wheels 41 rotate about a common axis of rotation 49 . The axis of rotation 49 runs perpendicular to the longitudinal center axis 46 . Arranged upstream of the axis of rotation 49 in the direction of travel 50 is the muffler 3 enclosed in the second housing 7 . The sound absorber 3 is arranged at the level of the axis of rotation 49 . The muffler 3 is in figure 1 Can't see it.

[0030] as in figure 2 As shown in , the muffler 3 is connected to the combustion motor 2 via a connecting line 4 . The muffler 3 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com