Efficient bearing ball mounting machine

A ball loader and bearing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of height deviation between steel balls and cages, steel balls are not easy to enter the ballway, and bearing service life is reduced, etc. The effect of high rate, good quality of ball loading and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

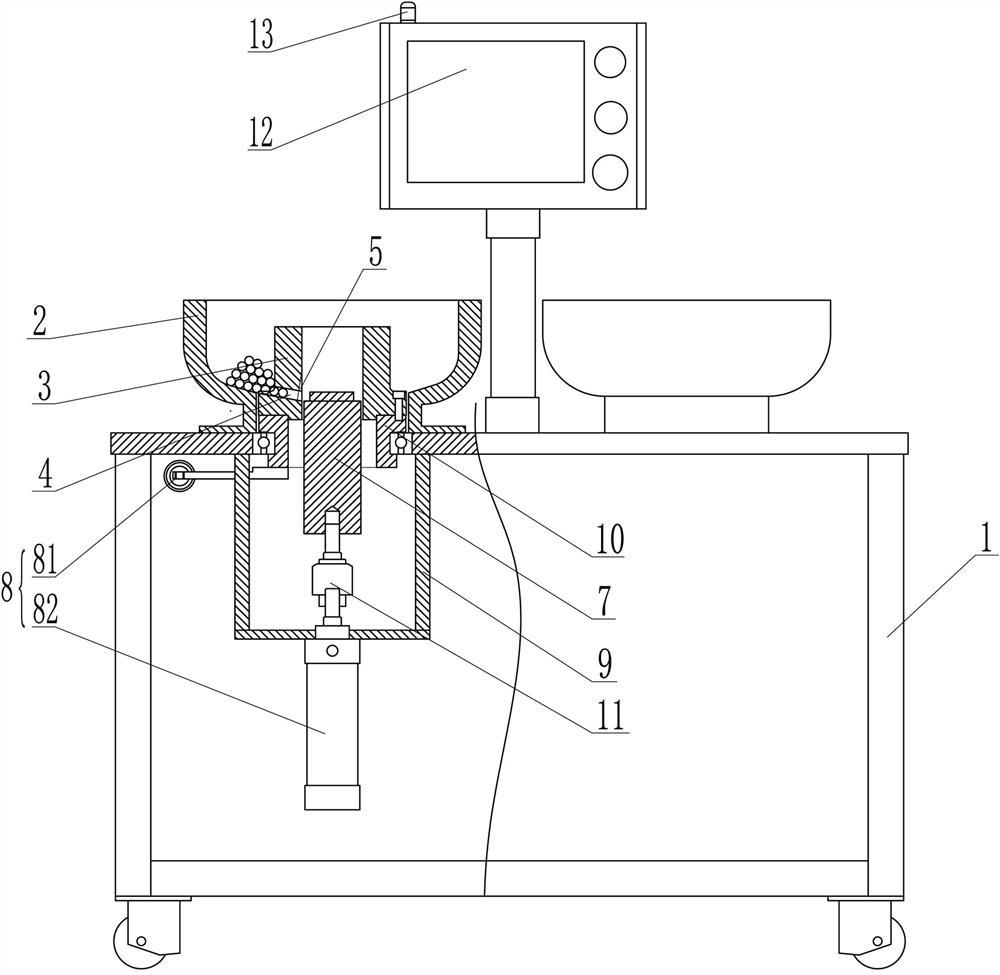

[0025] Embodiment Efficient bearing ball loading machine

[0026] This example figure 1 , figure 2 As shown, a high-efficiency bearing ball loading machine includes a table body 1, a ball loading device and a control device arranged on the table body 1, the table body 1 is provided with a runner, and the ball loading device is provided with two , to form a double station, and the two ball loading devices are controlled by one control device, saving production costs.

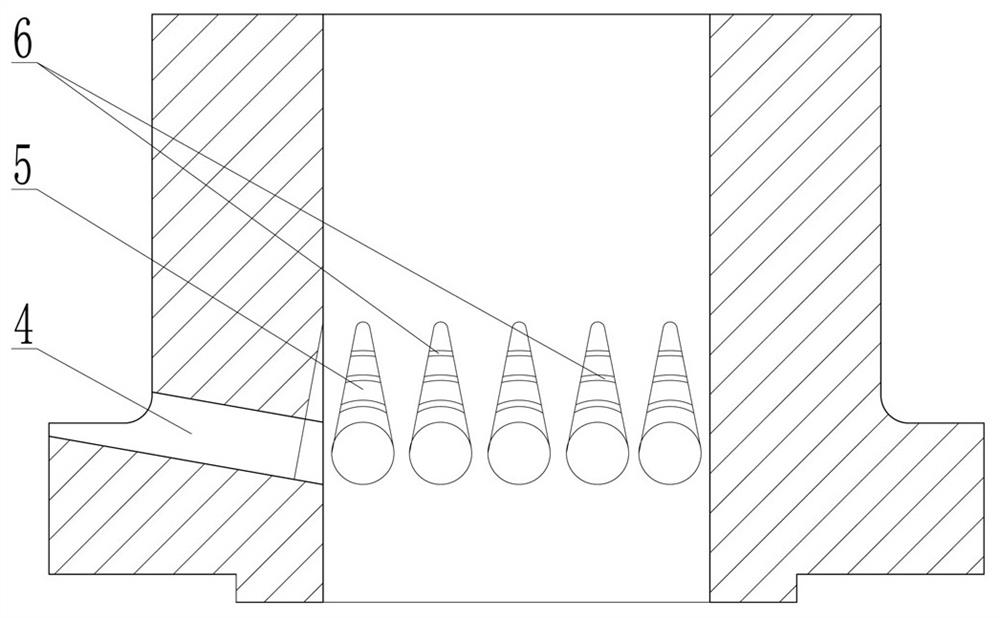

[0027] The ball loading device comprises a ball loading basin 2, a material distribution mold 3, a holder mold 7 and a driving device 8, and the ball loading basin 2 is fixed on the table top of the table body 1, and the inside of the ball loading basin 2 is Conical shape inclined towards the center, the center of the ball-loading basin 2 is provided with a circular hole for placing the distribution mold 3 .

[0028] The position corresponding to the round hole of the ball basin 2 on the table body 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com