Method for improving cutting utilization rate of glass

A glass cutting and utilization technology, applied in glass cutting devices, glass manufacturing equipment, data processing applications, etc., can solve the problems of reducing production line productivity, quality loss, return, etc., to achieve better quality, improve ease of use and efficiency , The effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

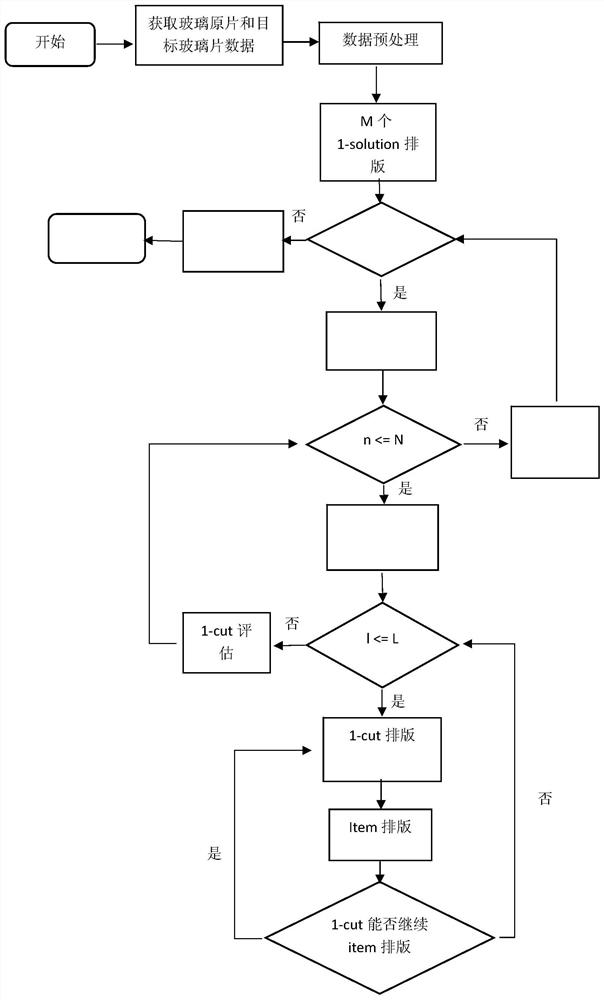

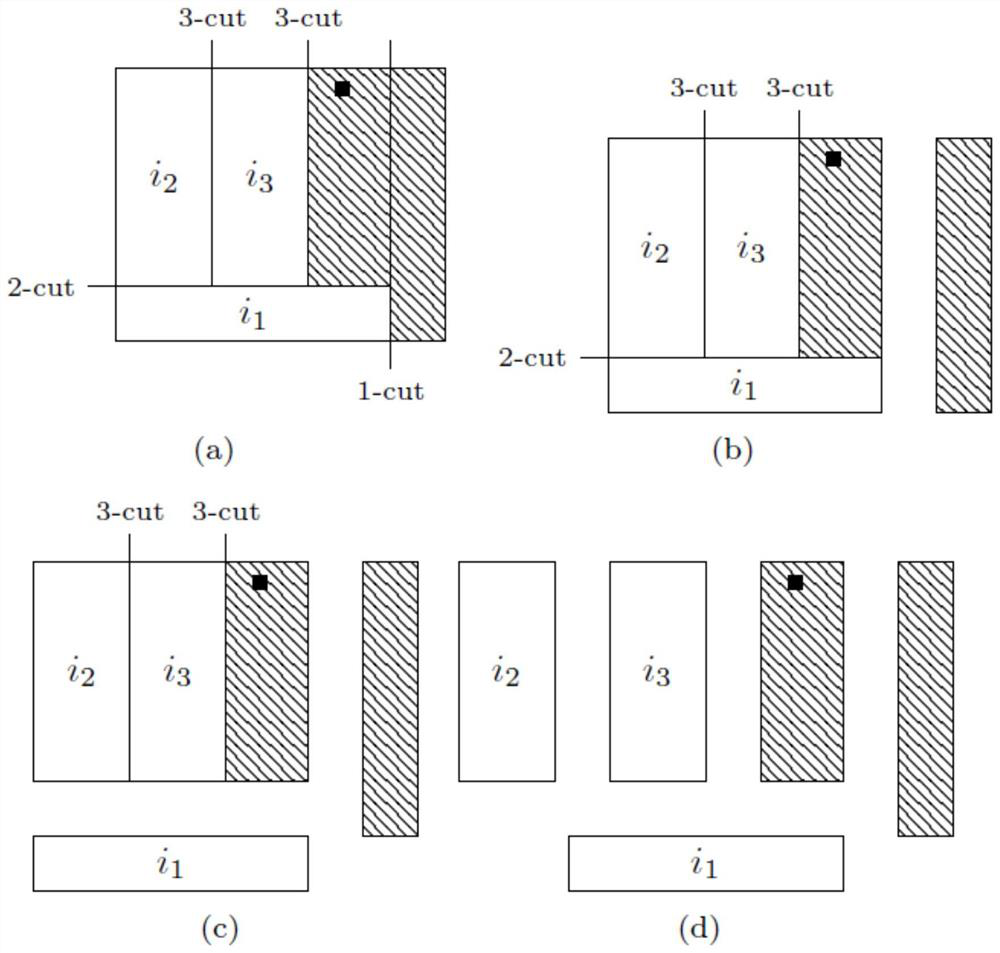

[0032] refer to figure 1 A method for improving the utilization rate of glass cutting provided by the present invention, the method includes obtaining glass information; the glass information includes size information of a target glass sheet and glass original sheet data, and the glass original sheet data includes original sheet size and Defect location and size information; according to the glass information, design a cutting and layout method for the original glass sheet through a heuristic cutting algorithm; cut the original glass sheet according to the cutting and layout method to obtain the target glass sheet.

[0033] The method is described in detail below:

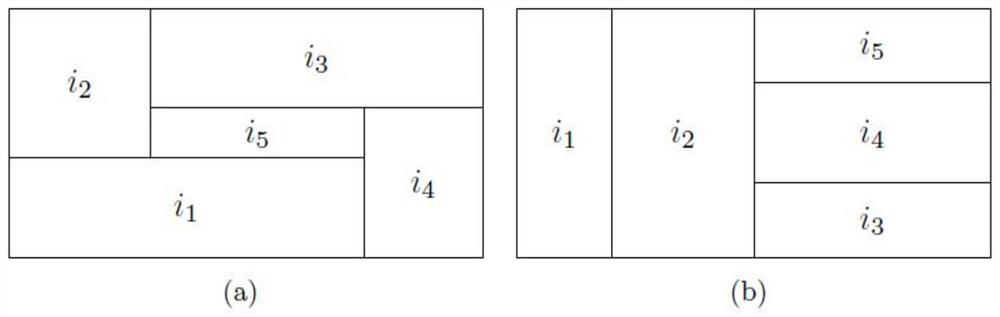

[0034] S11. Collect the information of the original glass plate (plate), such as: length, width, size of the defect, position of the defect, etc., and collect the length, width, stack (stack) and number of objects in the stack of the target glass plate (item). Sort (i 1 , i 2 , i 3 ...), for two terms i 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com