Laser power control method for building pipeline positioning and positioning equipment

A technology of laser power and control method, which is applied in the field of construction engineering, can solve the problems of economic loss of manpower and material resources, large error of pipeline position positioning, large error of floor slab size, etc., and achieve the effect of reducing construction cost and eliminating rework phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

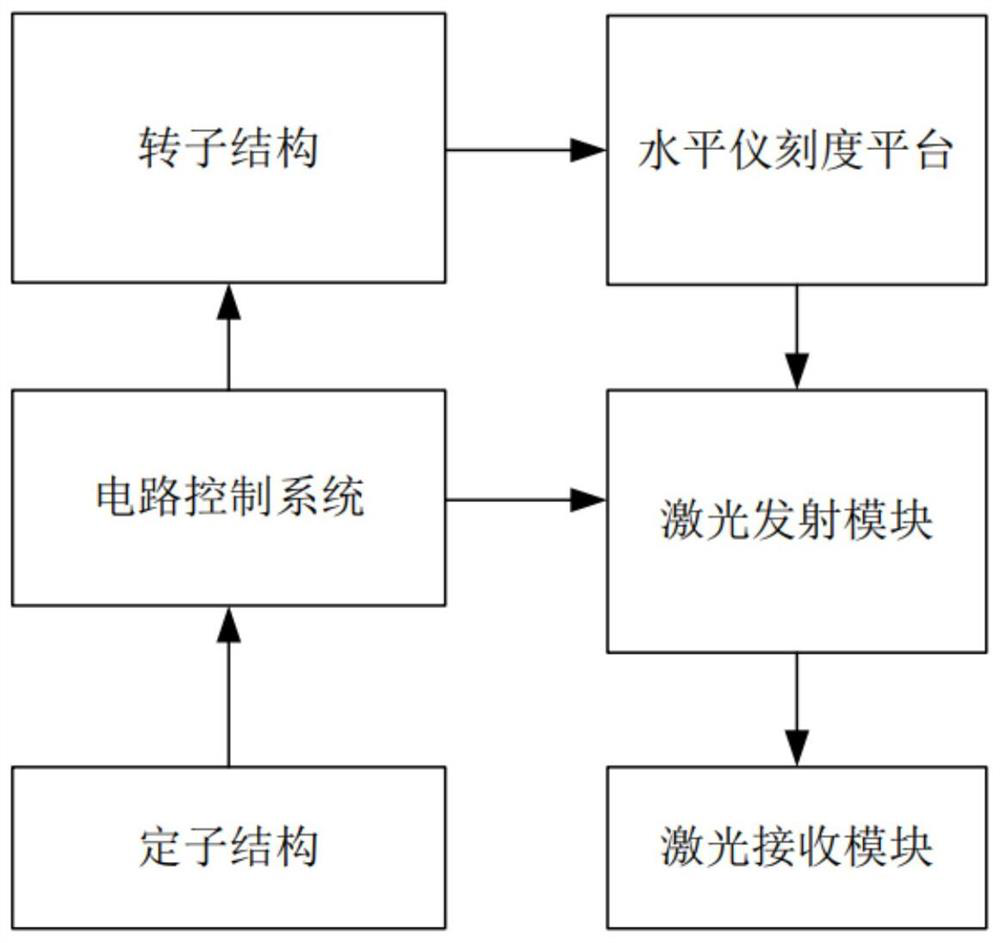

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A laser power control method for building pipeline positioning, comprising step 1, positioning the laser emitting module at the installation position of the bottom vertical pipeline of a high-rise or multi-storey building, as a reference positioning area; step 2, selecting a laser receiving module, the laser The characteristics of the receiving module are satisfied: a point mark with the same diameter as the laser beam can be displayed through laser irradiation, and when the laser beam keeps irradiating and moving, the point mark continues to be connected into a line mark; step 3, set the installation position of the laser receiving module The lower surface of the slab to be poured on each floor corresponding to the laser emitting module, and use this position as the set mark area; step 4, determine the vertical distance R between the reference positioning area and the set mark area of each floor according to the architectural drawings Step 5, according to the paramete...

Embodiment 2

[0056] On the basis of Embodiment 1, this embodiment has made further improvements, specifically:

[0057] In the step 6, the process of designing the positioning device includes the following specific steps:

[0058] Concrete steps B1, record the number of floors corresponding to the number of floors where the current intensity of the laser emission module required when each floor is marked by a temperature test paper, and write the data of each stall into the software of the circuit control system, and then write The software is downloaded to the main chip of the circuit control system;

[0059] Concrete step B2, according to the floor height data of the architectural drawings, convert the vertical distance R into the number of floors, and design the human-computer interaction device 4 based on this, that is, at least set the number of floors by clicking or inputting the floor on the human-computer interaction device 4 The operation module that can output the current intens...

Embodiment 3

[0062] On the basis of Embodiment 2, this embodiment has made further improvements, specifically:

[0063] Such as Figure 1-6 Shown:

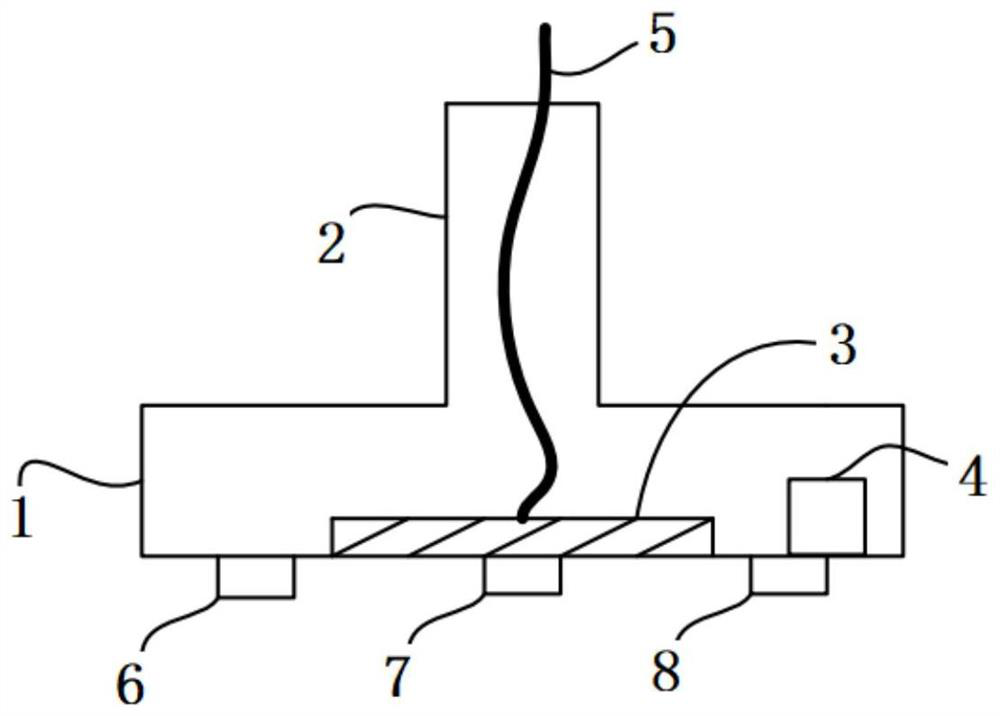

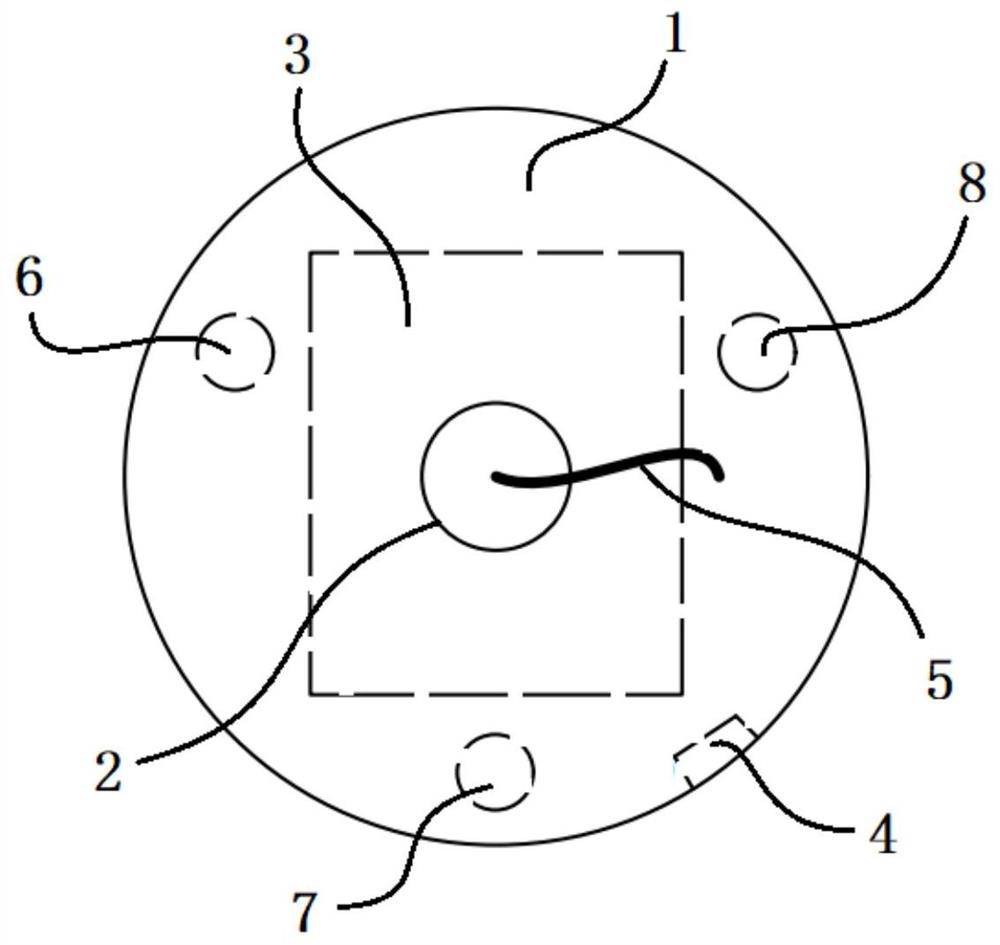

[0064] A positioning device of the present invention comprises a base 1, a stator 2 fixed longitudinally on the center of the upper surface of the base 1, a rotor 18 rotatably connected to the upper end of the stator 2, a level scale platform 11 fixedly connected to the upper end of the rotor 18, and a connecting The laser emission module 17 on the scale platform 11 of the level, the level 9 located on the upper surface of the scale platform 11, the circuit control system 3 installed on the base 1, the human-computer interaction device 4 installed on the outer surface of the base 1, and The laser receiving module 14, the base 1, the stator 2, the rotor 18, and the scale platform 11 of the level are coaxially arranged, and the laser emitting module 17 is detachably positioned on the upper surface of the scale platform 11 of the level through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com