Energy-saving and efficient honey concentrating device and honey concentrating method

A concentrating device and technology for honey, applied in separation methods, chemical instruments and methods, multi-effect evaporation, etc., can solve the problems of low commodity value and difficult sales for beekeepers, and achieve good social benefits, high clarity and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

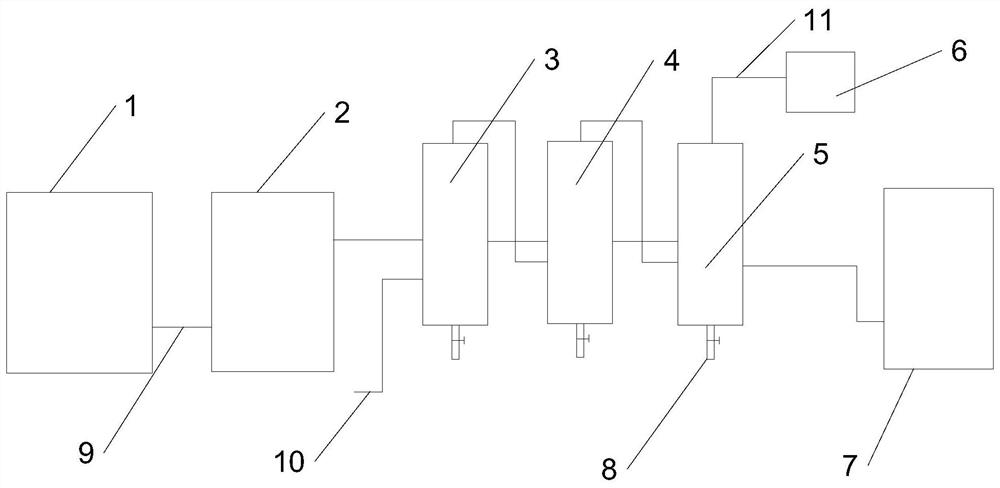

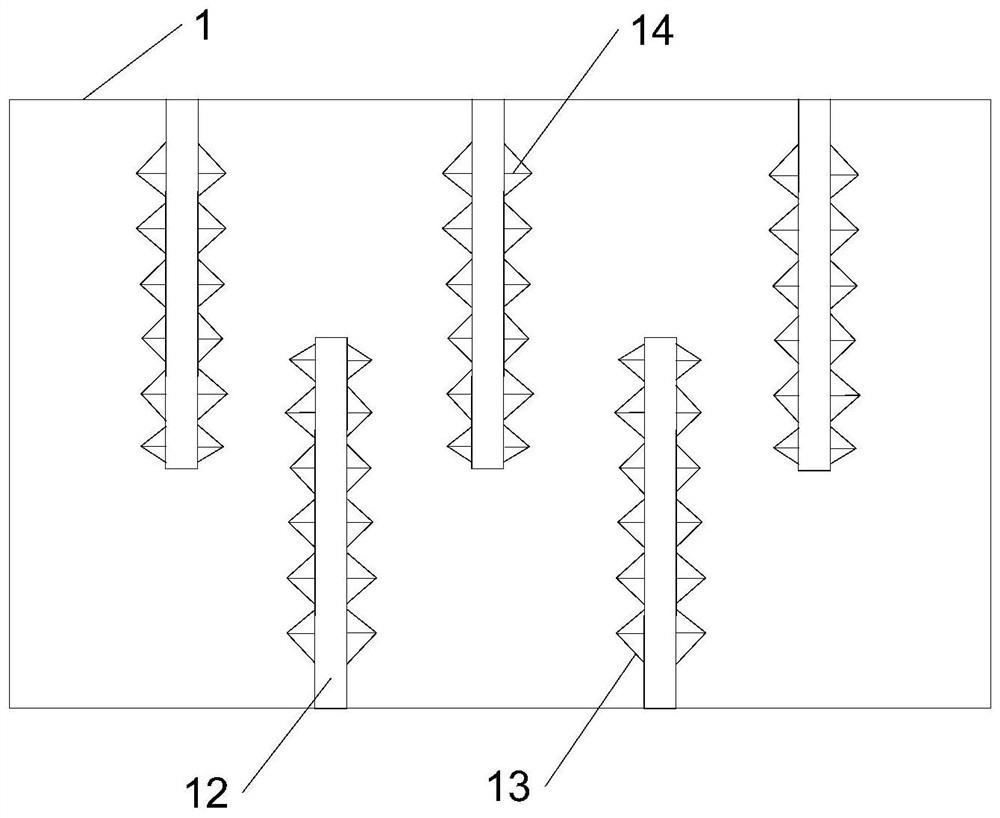

[0035] An energy-saving and high-efficiency honey concentration device includes a filter chamber, a buffer tank, a concentration device and an electric heating raw material tank, and the concentration device includes a first evaporator, a second evaporator and a third evaporator. The bottom of each evaporator of the concentration device is provided with a condensed water outlet pipe.

[0036] The lower part of the side wall of the filter chamber communicates with the lower part of the side wall of the buffer tank through the raw material pipe; the upper part of the opposite side wall of the buffer tank communicates with the middle part of the first evaporator through the raw material pipe; the side wall of the first evaporator is located below the raw material pipe and also With steam pipe.

[0037] The top of the first evaporator communicates with the middle part of the side wall of the second evaporator through a steam pipe, and the top of the second evaporator communicates ...

Embodiment 2

[0040] The present embodiment provides a kind of method utilizing the device of embodiment 1 to concentrate honey, comprises the steps:

[0041] (1) Get the linden tree honey with a moisture content of 23%, heat and melt to melt the liquid honey, then filter through the filter chamber, the macromolecular impurities are retained by the filter screen, and then enter the buffer tank through the raw material pipe;

[0042] (2) The filtered raw honey enters the first evaporator from the buffer tank, and simultaneously passes the steam from the steam pipe through the first evaporator to heat the raw honey;

[0043] (3) Raw honey passes through the second evaporator and the third evaporator successively from the first evaporator, and the steam from the top of the first evaporator enters the second evaporator and the third evaporator in turn, and heats and concentrates the raw honey, The raw honey enters the raw material tank after three-effect evaporation and concentration;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com