Numerically-controlled machine tool waste separating device and working method thereof

A technology of separation device and CNC machine tool, which is applied in the direction of magnetic separation, cleaning device, solid separation, etc., can solve the problems of troublesome waste treatment, inability to separate iron materials, and reduce waste treatment efficiency, so as to save electric energy, avoid repeated transportation, Reduce the effect of separation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

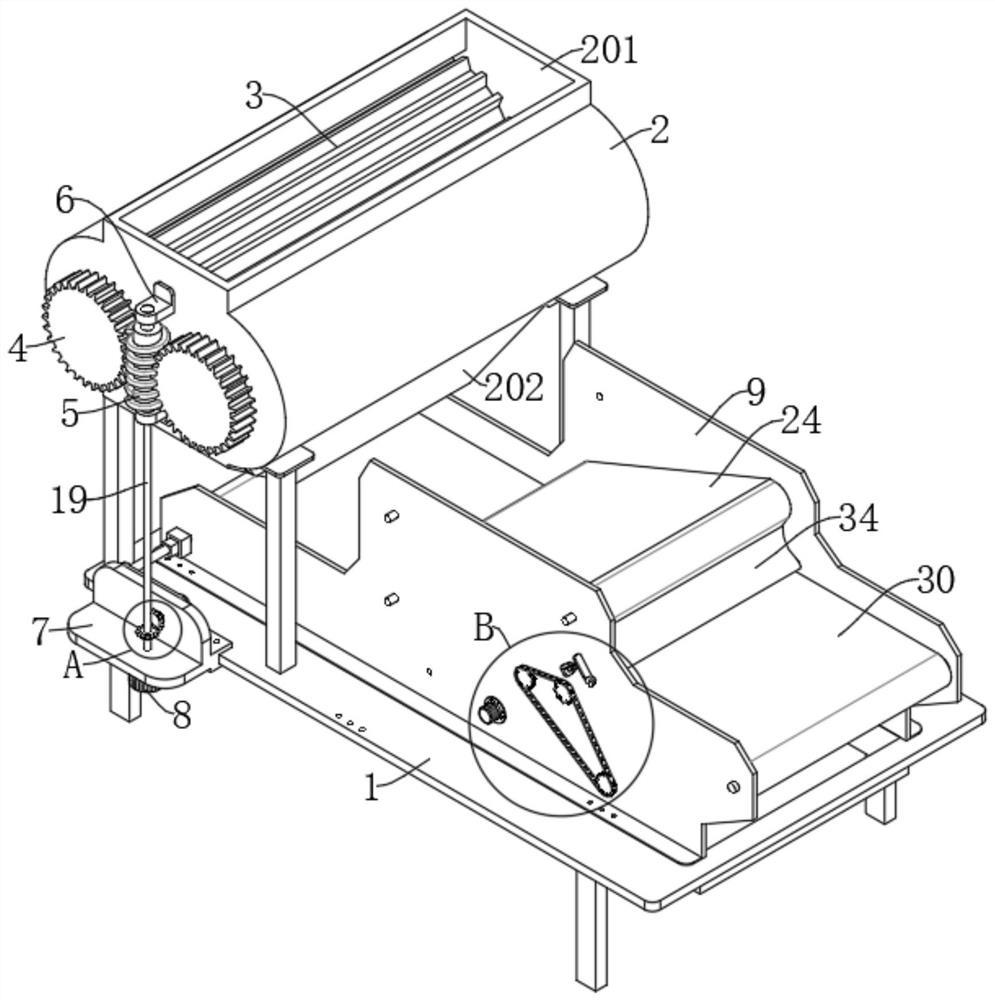

[0044] see Figure 1-10 , the technical solution provided by this embodiment is as follows:

[0045] A CNC machine tool waste separation device, comprising:

[0046] Workbench 1;

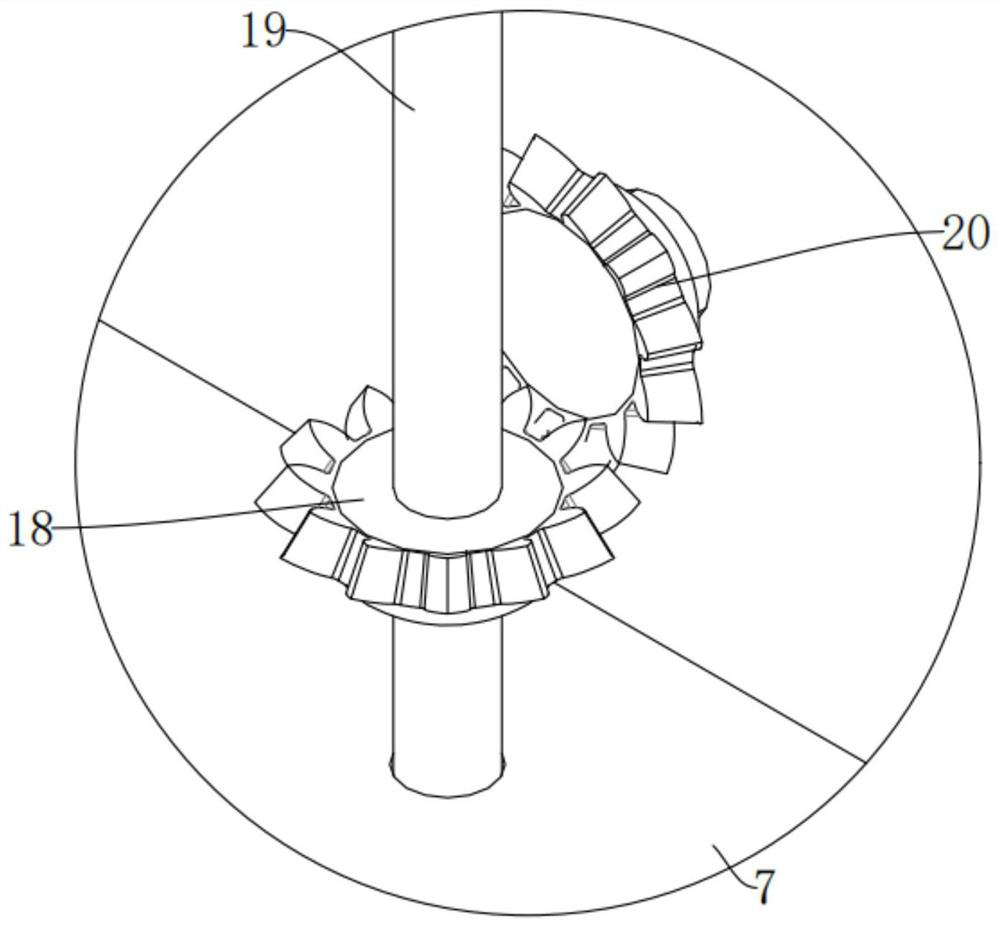

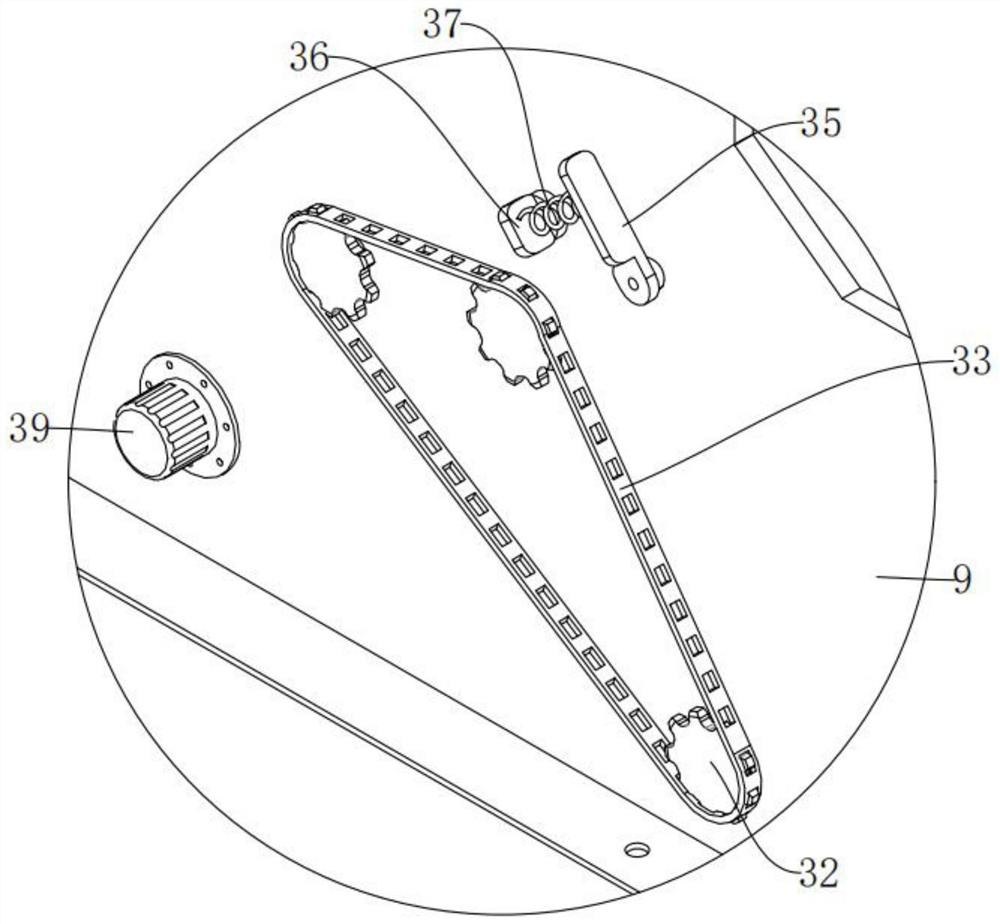

[0047] The crushing bin 2 is fixedly connected to the top of the workbench 1. The crushing bin 2 is provided with a feed port 201, a discharge port 202 and a crushing mechanism. The side of the workbench 1 is connected with a mounting frame 7 by bolts. The mounting frame 7 is provided with a driving mechanism, which is connected with the crushing mechanism to achieve crushing. The crushing mechanism includes two crushing teeth 3, two worm wheels 4 and a worm 5, and the two crushing teeth 3 are Rotationally connected between the side walls of the crushing bin 2, the two worm gears 4 are both rotatably connected to the side of the crushing bin 2, the axes of the two worm wheels 4 are fixedly connected to the crushing teeth 3 respectively, and the crushing bins Two mounting plates 6 are fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com