Efficient internal spraying type flotation machine

A flotation machine, high-efficiency technology, applied in the field of flotation machines, can solve the problems of increasing the difficulty of cleaning, the valve cannot be closed, and low work efficiency, so as to improve the overall work efficiency, improve the efficiency of feeding materials, and reduce the difficulty of cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

[0032] The present invention will be further described in detail below in conjunction with the examples and specific implementations.

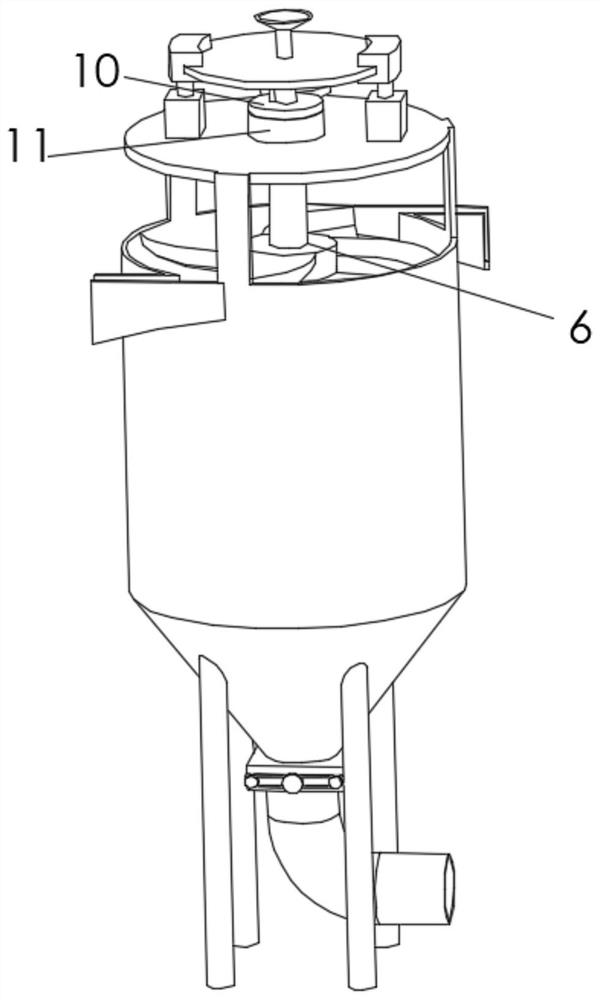

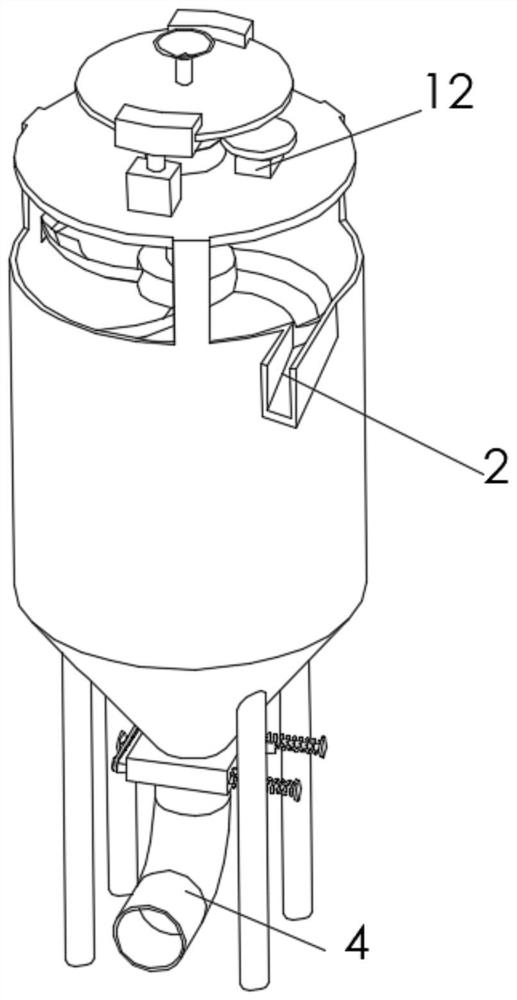

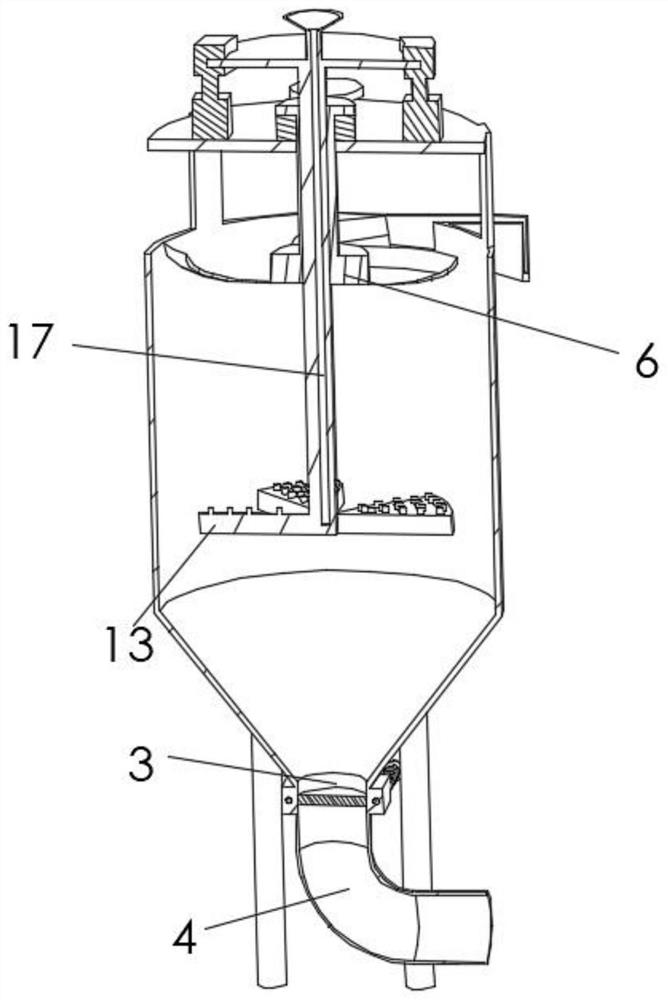

[0033] like figure 2 , Figure 4 As shown, a high-efficiency internal spray flotation machine includes: a mixing tank 1, and three supporting columns 32 are fixedly connected to the bottom of the mixing tank 1. The top of the mixing barrel 1 is provided with an opening, the open end of the mixing barrel 1 is provided with two concentrate discharge ports 2, and the mixing barrel 1 is arranged in a trumpet shape gradually narrowing from the middle end to the bottom end.

[0034] like image 3 , Figure 4 As shown, the bottom end of the mixing barrel 1 is provided with a tailings outlet 3, and the mixing barrel 1 is arranged in a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com