Cluster type steel coal storage hopper

A clustering and coal storage technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of large building plane size and unfavorable overall safety of the coal bunker structure, and achieve high lateral rigidity, simple structural internal force analysis, The effect of improving the anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

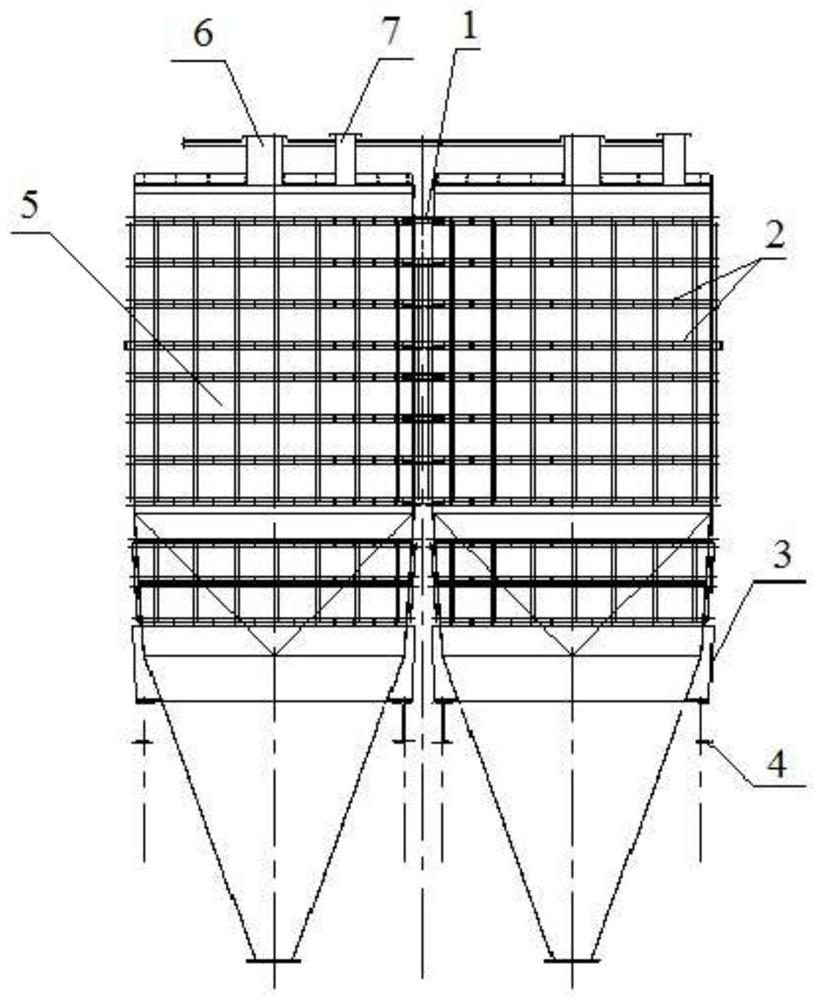

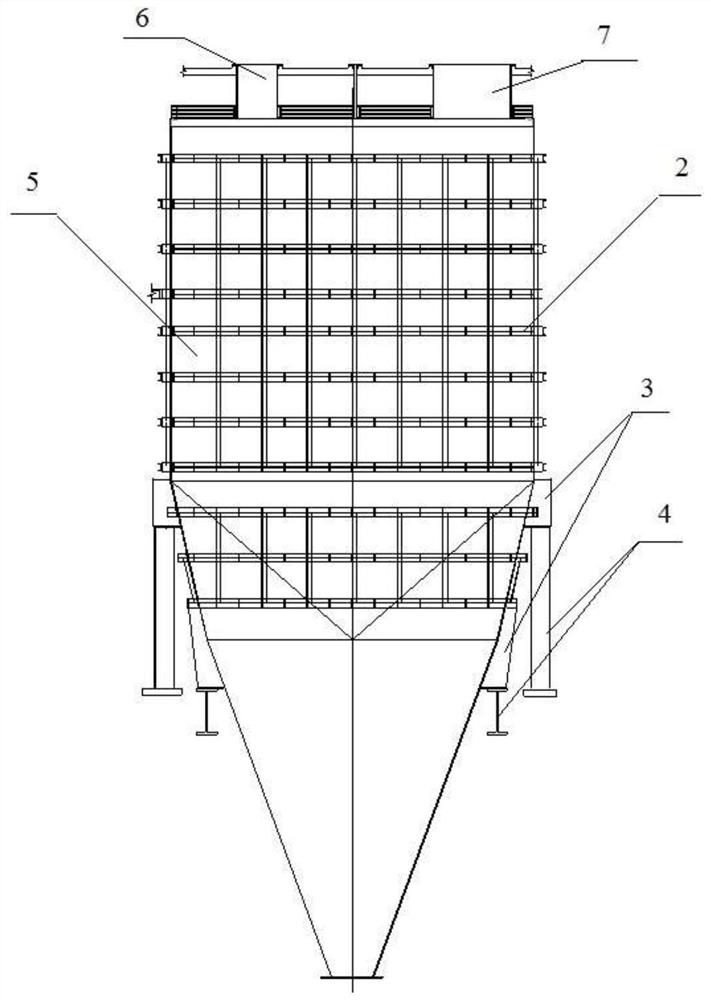

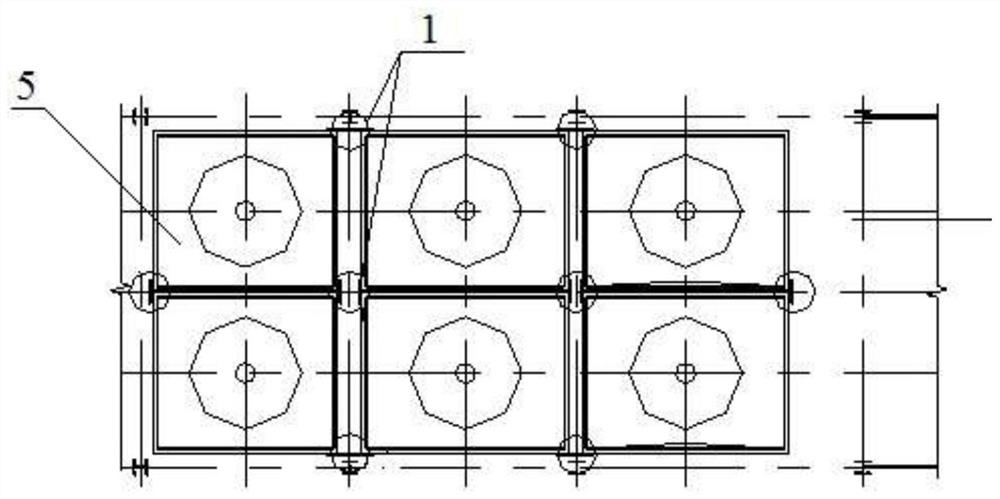

[0024] A cluster steel coal storage hopper, such as Figure 1-3 As shown, it includes a plurality of coal storage hoppers 5 arranged between the frame columns. The coal storage hopper 5 includes a rectangular straight section and a cone bucket section connected up and down, and the transition part of the rectangular straight section and the cone bucket section is provided with There are stiffeners 2 distributed horizontally and vertically, and a steel roof is provided on the top of the rectangular straight section, and the steel roof is provided with a coal drop hole 6 and a dust removal hole 7, and the position of the dust removal hole 7 is determined by the equipment requirements. The coal storage hopper 5 is fixed on the frame column through the coal storage hopper support 3 arranged on the side and the support beam 4 arranged below the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com