Method for hydrothermally assisted production of lignin activated carbon with high specific surface area

A high specific surface area, hydrothermally assisted technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of high production cost, complex activation process, limited range of lignin value-added, etc., and achieve production cost. Low cost, simple process operation and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

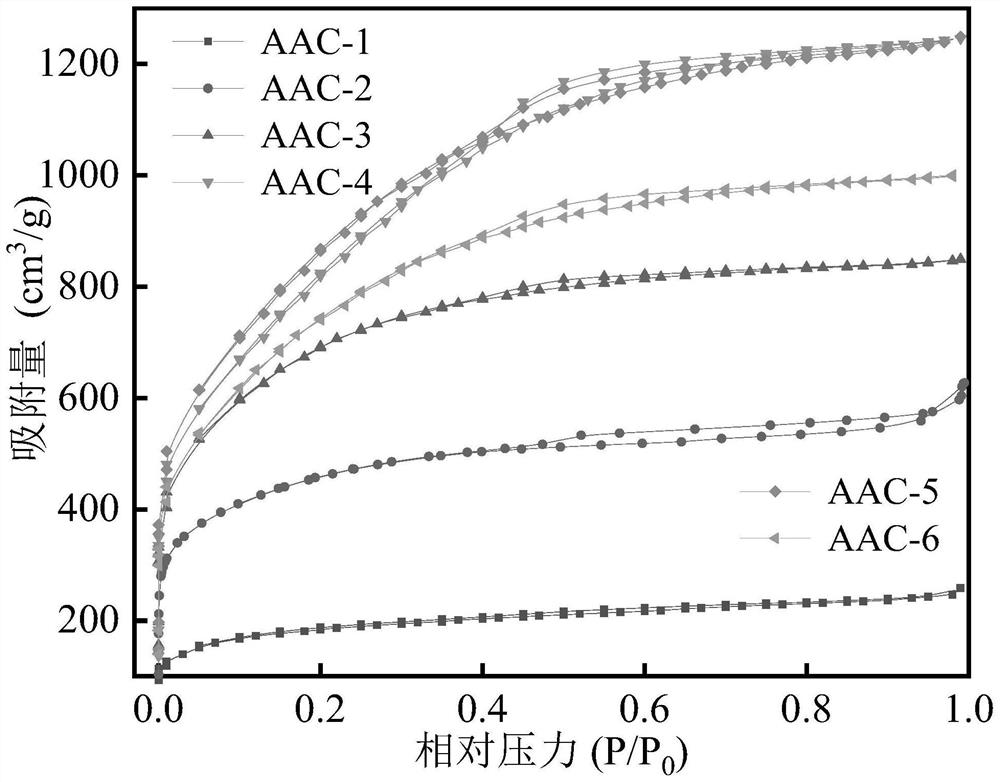

[0027] The nickel ark containing 5 g of lignin was placed in a high-temperature tube furnace, and the temperature was raised from room temperature to 900 °C at a rate of 10 °C / min in a nitrogen atmosphere of 200 mL / min, and kept at this temperature for 80 min. The tube furnace was cooled to room temperature, the samples were taken out, washed with water until neutral, and then dried in an oven at 105 °C to constant weight. That is, lignin pyrolytic carbon (named AAC-1) is obtained. through figure 2 Nitrogen adsorption-desorption curve test (analyzed by Autosorb-iQ automatic gas adsorption analyzer, the same below), the specific surface area of AAC-1 is 669.27 m 2 / g.

Embodiment 2

[0029] Put 5 g of lignin in a nickel ark, add 10 g of KOH and 10 mL of deionized water, and stir slowly until the mixture is uniform. Then, the nickel ark containing the mixture was placed in a high-temperature tube furnace, and the temperature was raised from room temperature to 900 °C at a rate of 10 °C / min in a nitrogen atmosphere of 200 mL / min, and kept at this temperature for 80 min. The tube furnace was cooled to room temperature, the samples were taken out, washed with acid and water until neutral, and then dried in an oven at 105 °C to constant weight. That is, a lignin activated carbon with a higher specific surface area (named AAC-2) is obtained. According to the nitrogen adsorption-desorption curve test, the specific surface area of AAC-2 is 1643.93 m 2 / g.

Embodiment 3

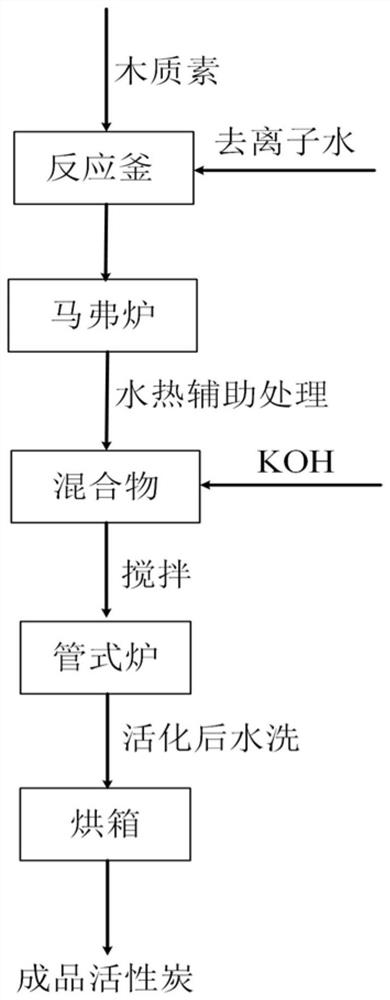

[0031] Such as figure 1 As shown, 5 g of lignin and 60 mL of deionized water were placed in the reactor and mixed evenly, and then the reactor was placed in a muffle furnace at 100 °C for 2 hours. The reactor was cooled to room temperature, poured out the hydrothermally assisted treated mixture into a nickel ark and added 10 g KOH, and stirred slowly until the mixture was uniform. Then put the nickel ark containing the mixture (mixed evenly) in a high-temperature tube furnace, in a nitrogen atmosphere of 200 mL / min, from room temperature to 900 °C at a rate of 10 °C / min, and at this temperature Keep warm for 80 min. The tube furnace was cooled to room temperature, the samples were taken out, washed with acid and water until neutral, and then dried in an oven at 105 °C to constant weight. That is, lignin activated carbon with high specific surface area (named AAC-3) is obtained. According to the nitrogen adsorption-desorption curve test, the specific surface area of AAC-3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com