Antique white-green glaze and preparation method thereof, and preparation method of antique white-green glaze ceramic product

A technology of ceramic products and white-green glaze, applied in the field of ceramics, can solve problems such as broken and achieve the effect of stable molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

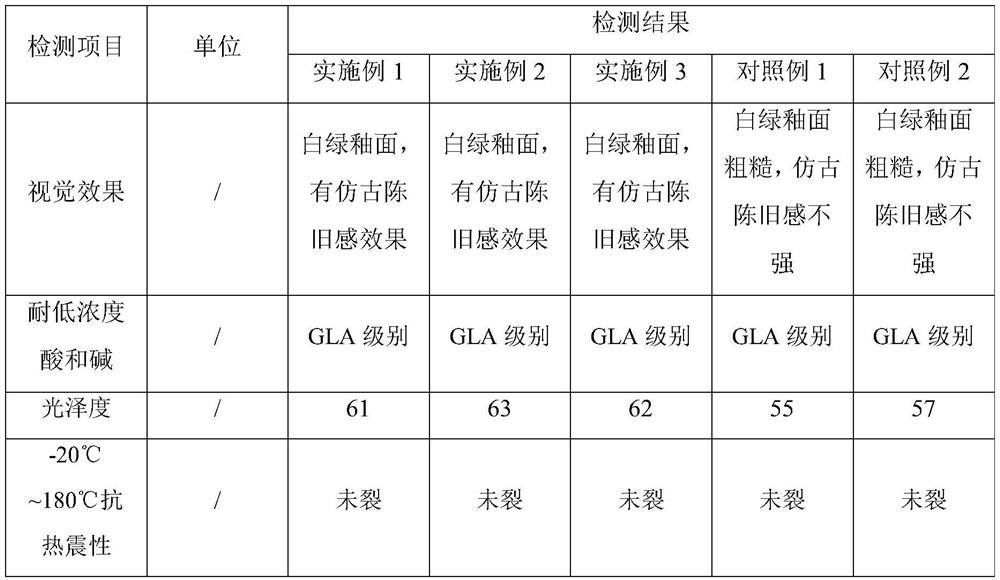

Examples

Embodiment 1

[0031] The antique white-green glaze includes the following components in parts by mass: 70 parts of kaolin, 6 parts of feldspar, 5 parts of quartz, 2 parts of zinc oxide, 3 parts of calcium carbonate, 13 parts of antimony ore, and 7 parts of wollastonite 6 parts of chalk, 11 parts of diabase, 1 part of iron oxide, and 5 parts of medical stone.

[0032] The preparation method of antique white-green glaze comprises the following steps:

[0033] Step 1. Broken

[0034] According to the number of parts by mass, the kaolin, feldspar, quartz, calcium carbonate, antimony ore, wollastonite, chalk, diabase and medical stone are respectively crushed and then mixed and stirred to obtain crushed material, and sieved for later use;

[0035] Step two, ball milling

[0036] According to the number of parts by mass, the crushed material obtained in step 1 is mixed with the zinc oxide and iron oxide, then ball milled, and sieved to obtain a ball mill;

[0037] Step 3. Beating

[0038] Be...

Embodiment 2

[0049] Antique white and green glaze, including the following components in terms of parts by mass: 75 parts of kaolin, 7 parts of feldspar, 6 parts of quartz, 3 parts of zinc oxide, 5 parts of calcium carbonate, 16 parts of antimony ore, and 8 parts of wollastonite 7 parts of chalk, 14 parts of diabase, 2 parts of iron oxide, 7 parts of medical stone.

[0050] The preparation method of antique white-green glaze comprises the following steps:

[0051] Step 1. Broken

[0052] According to the number of parts by mass, the kaolin, feldspar, quartz, calcium carbonate, antimony ore, wollastonite, chalk, diabase and medical stone are respectively crushed and then mixed and stirred to obtain crushed material, and sieved for later use;

[0053] Step two, ball milling

[0054] According to the number of parts by mass, the crushed material obtained in step 1 is mixed with the zinc oxide and iron oxide, then ball milled, and sieved to obtain a ball mill;

[0055] Step 3. Beating

[...

Embodiment 3

[0067] Antique white and green glaze, including the following components in parts by mass: 80 parts of kaolin, 8 parts of feldspar, 7 parts of quartz, 5 parts of zinc oxide, 6 parts of calcium carbonate, 20 parts of antimony ore, and 8 parts of wollastonite 9 parts of chalk, 17 parts of diabase, 3 parts of iron oxide, 11 parts of medical stone.

[0068]The preparation method of antique white-green glaze comprises the following steps:

[0069] Step 1. Broken

[0070] According to the number of parts by mass, the kaolin, feldspar, quartz, calcium carbonate, antimony ore, wollastonite, chalk, diabase and medical stone are respectively crushed and then mixed and stirred to obtain crushed material, and sieved for later use;

[0071] Step two, ball milling

[0072] According to the number of parts by mass, the crushed material obtained in step 1 is mixed with the zinc oxide and iron oxide, then ball milled, and sieved to obtain a ball mill;

[0073] Step 3. Beating

[0074] Bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com