Mortar pasting system for building external wall insulation board

A technology for building exterior walls and thermal insulation boards, which is applied in construction, building structure, and building material processing, etc., can solve the problems of falling off, affecting the construction period, and low bonding efficiency, and achieves the effect of uniform thickness, high speed and the same spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

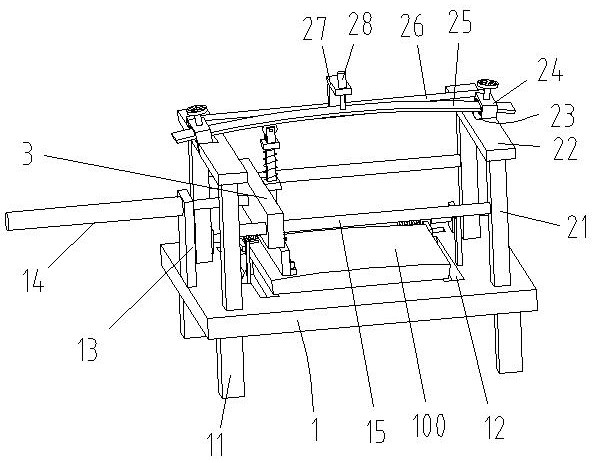

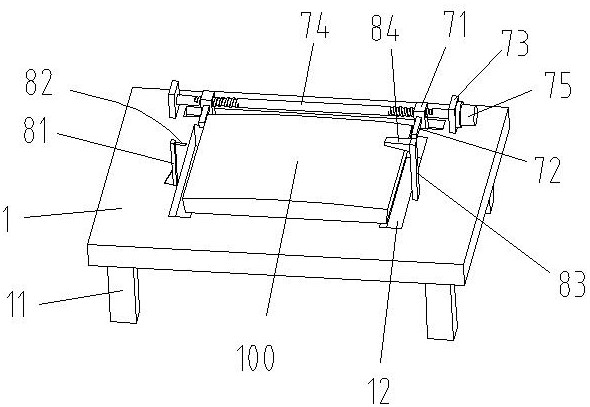

[0028] Such as Figure 1-Figure 8 As shown, a mortar system for pasting thermal insulation boards of building exterior walls provided by the present invention includes a base plate 1, a plurality of support columns 11 are fixedly connected to the bottom of the base plate 1, and a clamping device for clamping the thermal insulation board is provided on the upper side of the base plate 1. The tightening device comprises two vertical plates 73 arranged in parallel, and the two vertical plates 73 are all fixed on the upper side of the base plate 1, and the rotating shaft 74 is connected between the vertical plates 73, and the rotating shaft 74 is provided with a left-handed thread segment and a right-handed thread segment, and the base plate 1. Guide grooves are provided on the upper side, and slide blocks 71 are slidably connected in each guide groove. One of the slide blocks 71 is provided with a left-handed threaded hole, and the other slide block 71 is provided with a right-han...

Embodiment 2

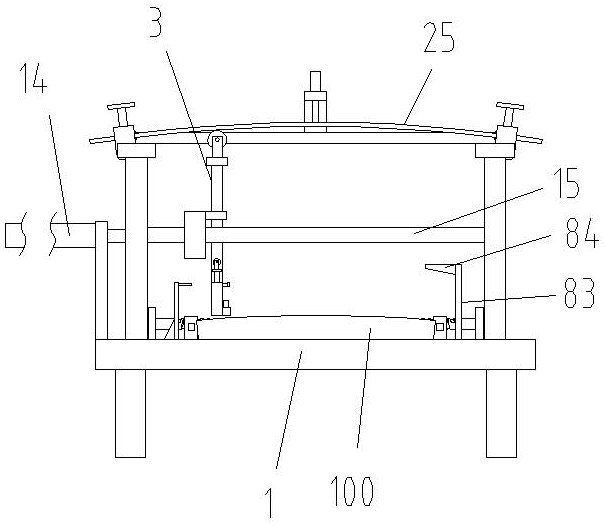

[0033]Since part of the wall is arc-shaped, and the insulation board of this type of wall is also arc-shaped, in order to apply cement mortar to the arc-shaped insulation board, a curvature adjustment device 2 is installed on the upper side of the bottom plate 1, and the curvature The adjusting device 2 includes two supports, and the supports include a top beam 22 , and the top beam 22 is supported and fixed by two supporting shafts 21 . The fixed shaft 15 is fixedly connected between the brackets. One side of the base plate 31 is provided with a fixed hole. The fixed shaft 15 passes through the fixed hole. The base plate 31 can slide along the fixed shaft 15 outlets through the fixed hole. Each top beam 22 is provided with Hinged groove 23, all rotations connect fixed block 24 in each hinged groove 23, each fixed block 24 one side is all provided with installation groove, is provided with elastic plate 25 between two fixed blocks 24, and elastic plate 25 two ends insert respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com